Preparation method of hybrid hydrolase formulation for promoting methane yield from fermentation

A biogas fermentation and hydrolase technology is applied in the field of preparation of supplementary exogenous enzymes, which can solve the problems of time difference, high requirements for enzyme activity indicators, and no production method for mixed enzyme preparations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

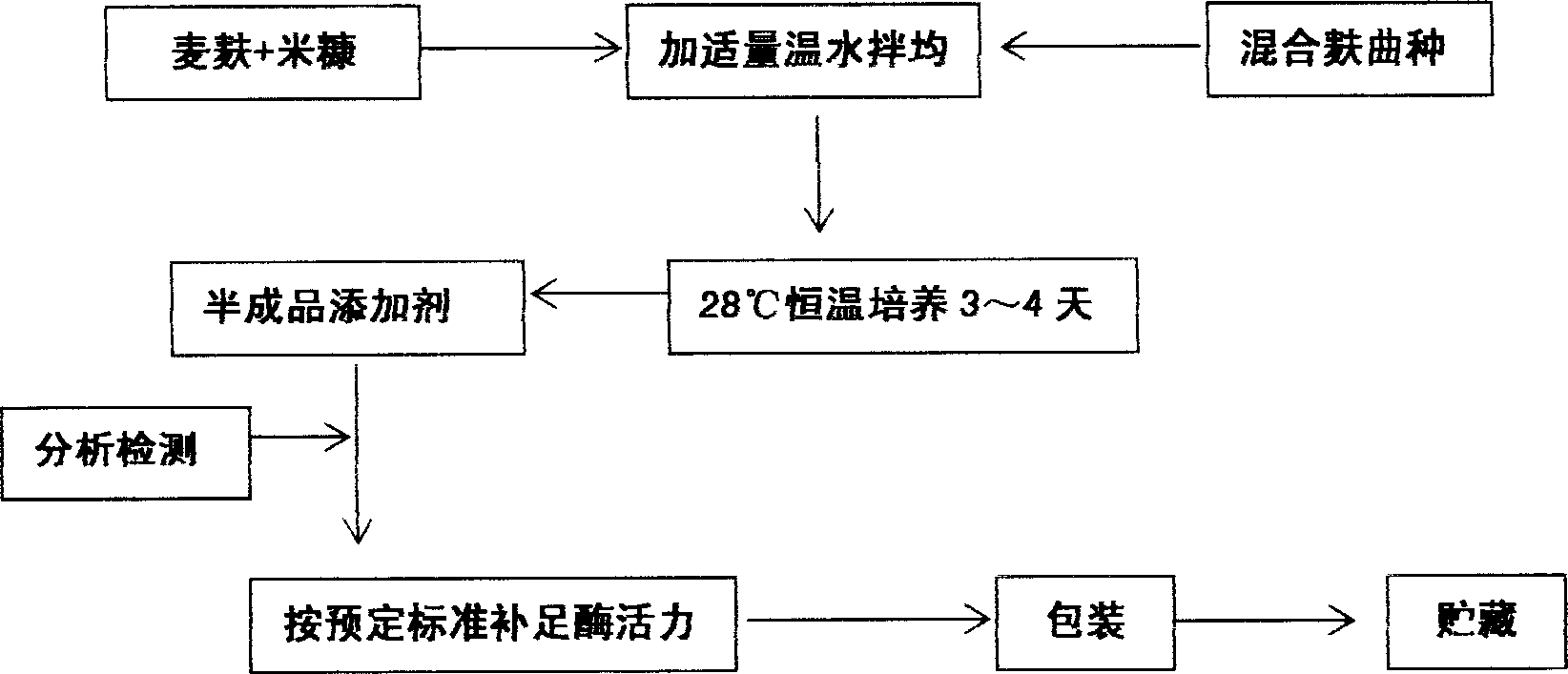

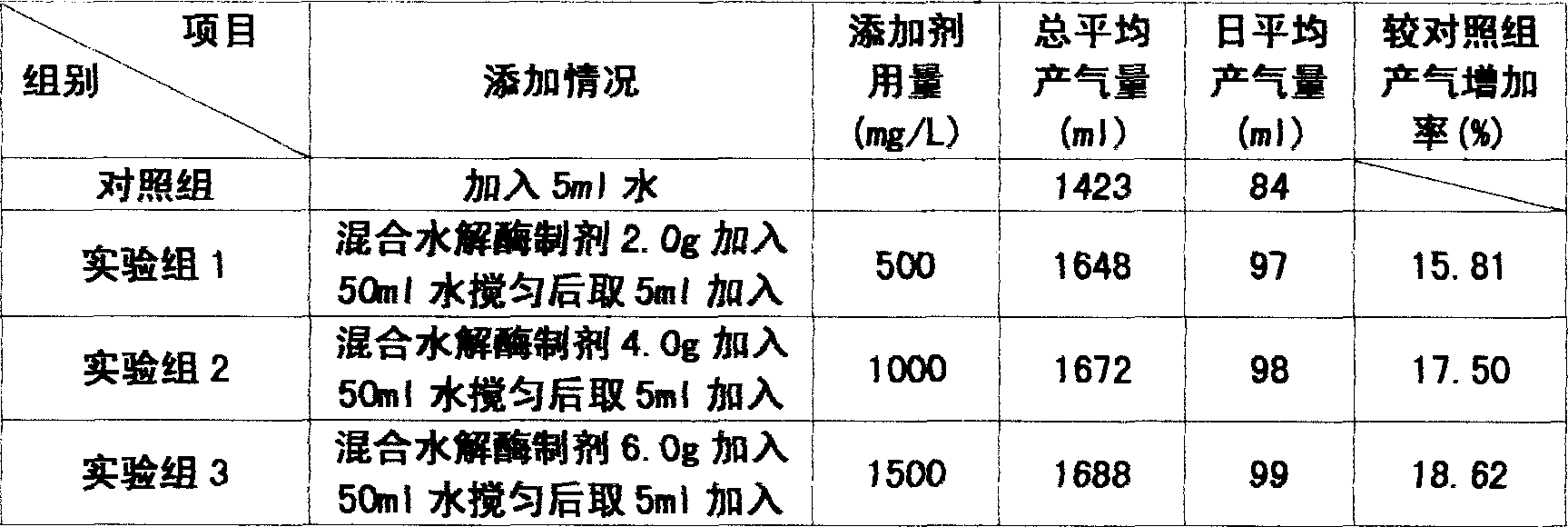

[0016] (1) Preparation of mixed hydrolytic enzyme preparation

[0017] The preparation of the mixed hydrolytic enzyme preparation of the present invention involves two parts: seed production and product production. The first is that the seed production process adopts pure strain solid-state method to sterilize the clinker to expand, and cultivate the seeds for gluten production; the other is that the product production process adopts Wheat bran raw materials are fermented, and commercial enzyme preparations are added appropriately.

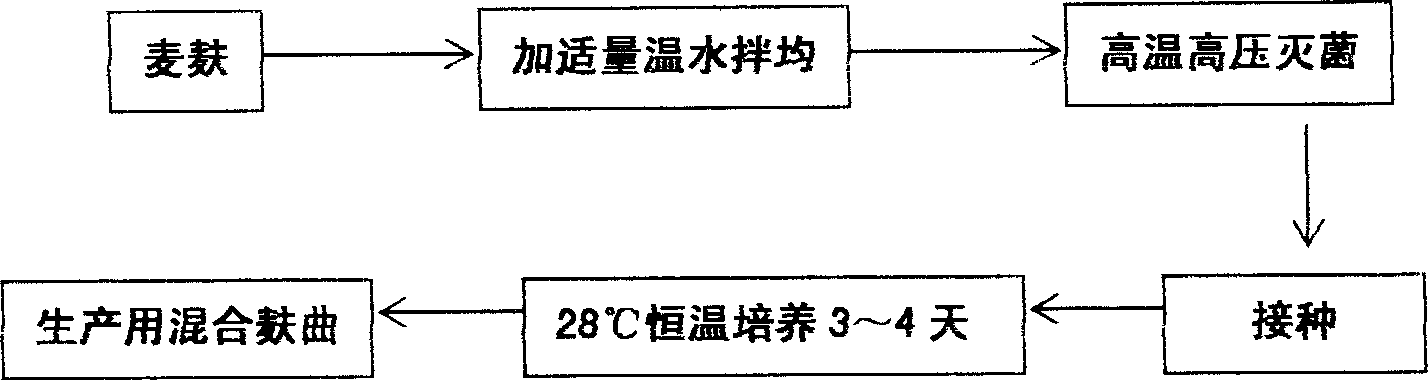

[0018] Such as figure 1 , using wheat bran as the medium, adding water until the water content of wheat bran is 60-70% to make a slurry, distributing them in test tubes or 250mL Erlenmeyer flasks, sterilizing at 121°C for 30 minutes, and putting them into the required ingredients after cooling. For the pure slant strains of the strains, cultivate them at a constant temperature of 28°C until the strains are covered with whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com