Heat-resistant polylactic acid composite material with short degradation cycle and preparation method of composite material

A degradation cycle and composite material technology, applied in sustainable manufacturing/processing, flexible coverings, bio-packaging, etc., can solve the problems of not being able to meet the harsh conditions of composting, not being able to fully achieve degradation, and degradation is not very common, etc., to achieve Expand usage scenarios, achieve controllable degradation, and fast degradation rate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

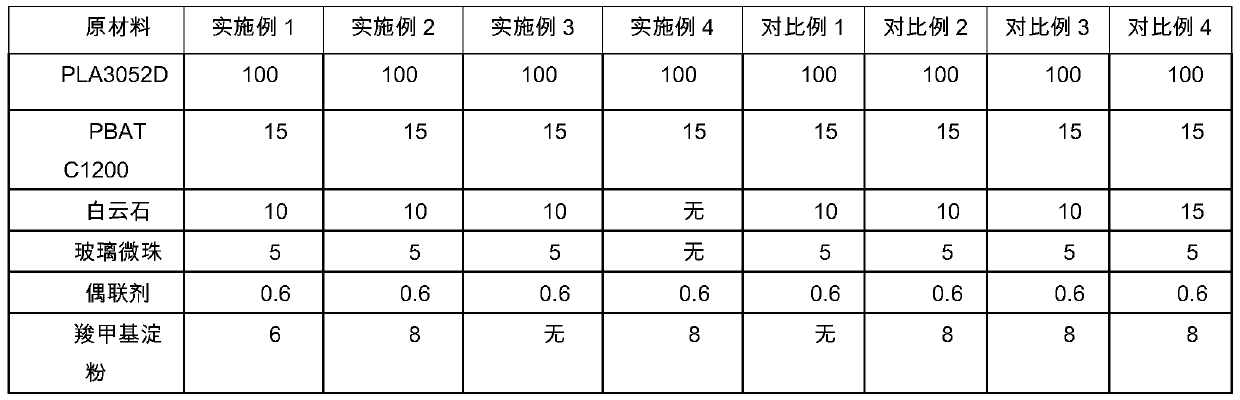

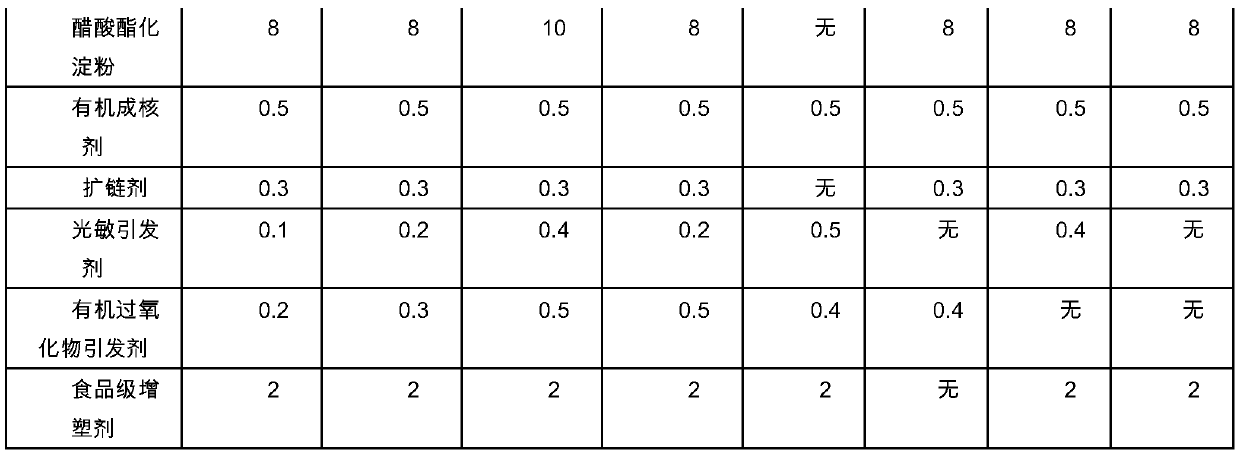

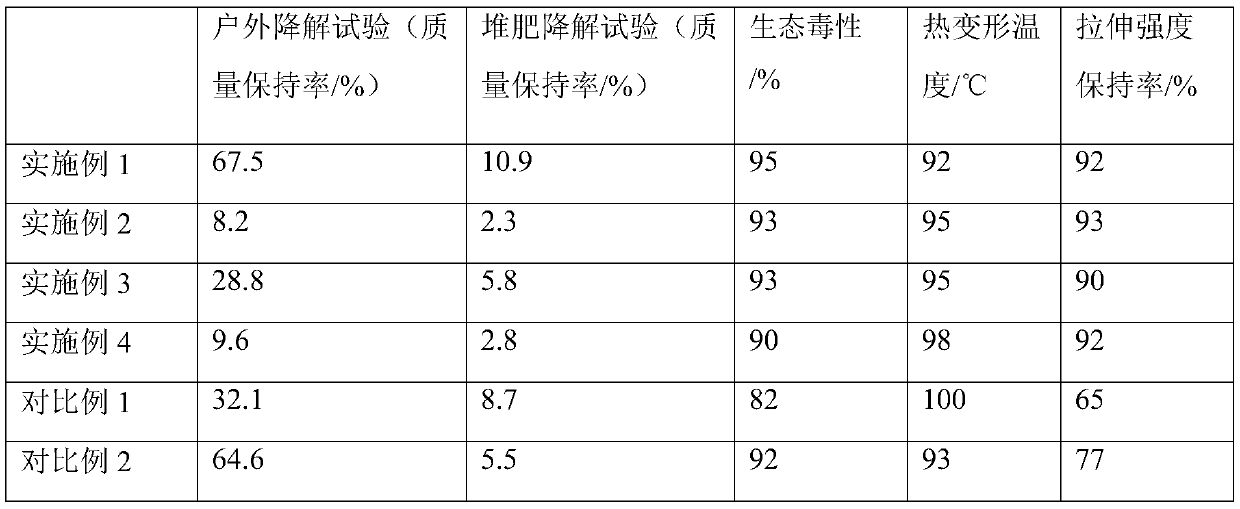

Examples

preparation example Construction

[0045] The preparation method of the heat-resistant polylactic acid composite material made of above-mentioned raw material components comprises the following steps:

[0046] (1) Dry the polylactic acid resin, PBAT resin, inorganic filler and modified starch for use, the drying time is 3 to 5 hours, and the temperature is 80°C;

[0047] (2) Mix modified starch, organic nucleating agent, chain extender, thermo-oxidative degradation initiator, and compound photoinitiator in a high-mixer according to the mass ratio, and the rotating speed is 600r / min, the time is 5min, and the temperature Control at 60°C to obtain a degradation aid premix in which the thermo-oxidative degradation initiator and compound photoinitiator are fully coated with modified starch;

[0048] (3) Put the polylactic acid resin, PBAT resin, inorganic filler, and coupling agent in a high-speed mixer according to the mass ratio, mix and stir evenly, the rotation speed is 800r / min, the time is 5min, and the tempe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com