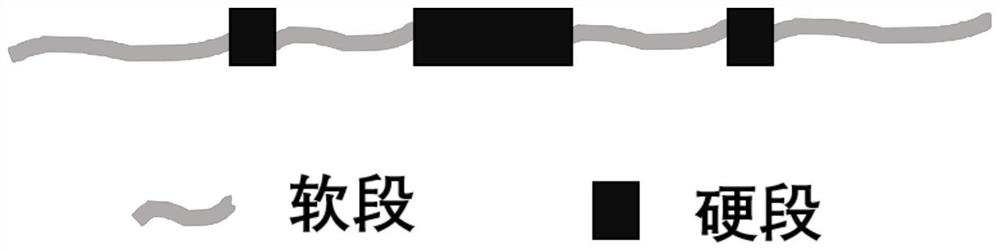

A self-healing anti-aging controllable degradable polyurethane and its preparation method and application

An anti-aging, self-healing technology, applied in the field of polyurethane, to achieve the effect of simple process, not easy to degrade, and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

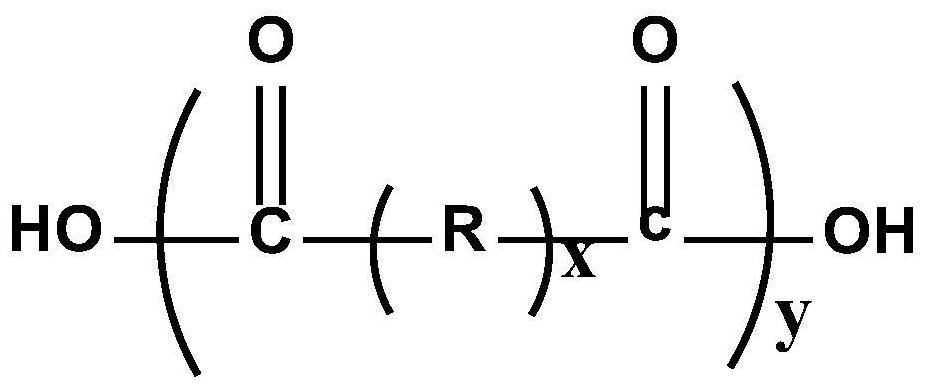

[0049] Another aspect of the embodiments of the present invention also provides a method for preparing the self-healing anti-aging controllable degradation polyurethane, which includes:

[0050] Under a protective atmosphere, the mixed reaction system comprising polydiol, isocyanate, chain extender, catalyst, isocyanate and solvent is reacted at 25-100°C for 1-48 hours to prepare self-healing anti-aging controllable degradation polyurethane.

[0051] In some more specific embodiments, the preparation method specifically includes:

[0052] In a protective atmosphere, mix polyglycol, isocyanate, chain extender, catalyst and solvent and heat at 25-100°C until completely dissolved, then add isocyanate to form the mixed reaction system, and control the reactant in the mixed reaction system The concentration is 10-50 wt%, and then reacted at 25-100° C. for 1-48 hours, and then after-treatment to obtain the self-healing anti-aging controllable degradable polyurethane.

[0053] Furth...

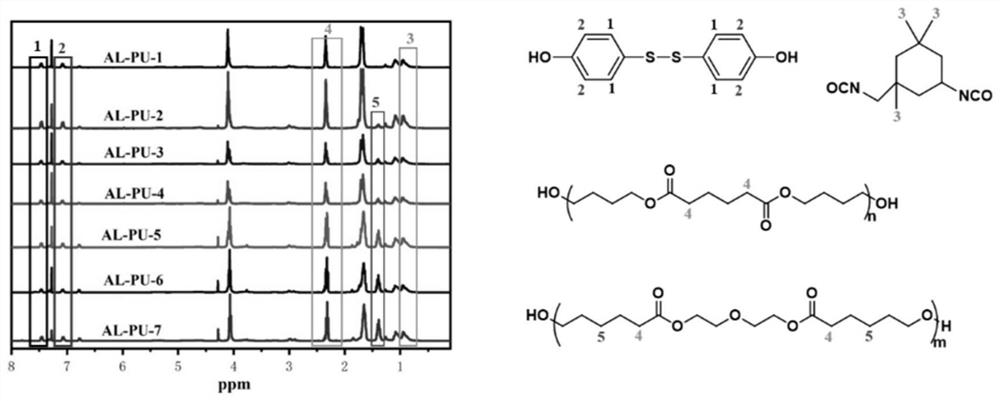

Embodiment 1

[0070] In a glove box filled with 99.999% Ar, fresh polybutylene adipate diol, polycaprolactone diol, bis(4-hydroxyphenyl) disulfide, dibutyltin dilaurate and Tetrahydrofuran is added to a three-neck reactor equipped with a mechanical stirrer for a one-step reaction, wherein [polybutylene adipate diol + polycaprolactone diol] / [bis(4-hydroxyphenyl) diol] Sulfur ether]=1 / 99 (mass ratio), the molecular weight of polybutylene adipate diol and polycaprolactone diol is 600g / mol, polybutylene adipate diol and polycaprolactone The molar ratio of ester diol is 1:1, dibutyltin dilaurate accounts for 0.1wt% of the total mass of reactants, the molar ratio of hydroxyl groups to isocyanate groups is 0.5:1, and the concentration of all reactants is 10wt%, The reaction temperature is 25°C, and the reaction time is 1h. Finally, the polymer precipitate is washed several times with distilled water, and vacuum-dried at 60°C for 12h to constant weight to obtain the polyurethane PU-1 (see image...

Embodiment 2

[0072] In a glove box filled with 99.999% Ar, fresh polybutylene adipate diol, polycaprolactone diol, bis(4-hydroxyphenyl) disulfide, dibutyltin dilaurate and Tetrahydrofuran was added into a three-neck reactor equipped with a mechanical stirrer for one-step reaction. Among them, [polybutylene adipate diol + polycaprolactone diol] / [bis (4-hydroxyphenyl) disulfide] = 50 / 50 (mass ratio), polybutylene adipate The molecular weight of alcohol ester diol and polycaprolactone diol is 600g / mol, the molar ratio of polybutylene adipate diol to polycaprolactone diol is 1:1, dibutyltin dilaurate accounts for the reaction 0.1wt% of the total mass of the reactants, the molar ratio of hydroxyl groups to isocyanate groups is 0.5:1, the concentration of all reactants is 10wt%, the reaction temperature is 25 ° C, the reaction time is 1h, and finally the polymer is precipitated with distilled water After washing several times, vacuum-dry at 60° C. for 12 h to constant weight to obtain the pol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com