Method for preparing mesoporous silica spherical nanoparticles

A mesoporous silica and nanoparticle technology, applied in the direction of silica, silicon oxide, nanotechnology, etc., can solve the problems of unfavorable large-scale production, irregular particle shape, harsh conditions, etc., and achieve the convenience of macro-synthesis, The effect of uniform pore size and regular shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

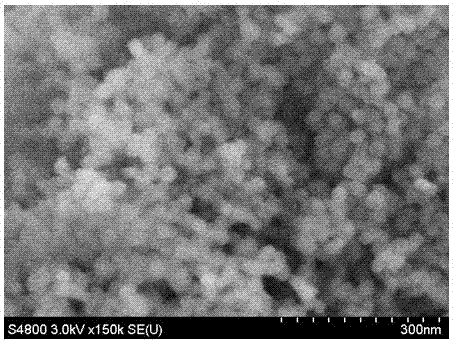

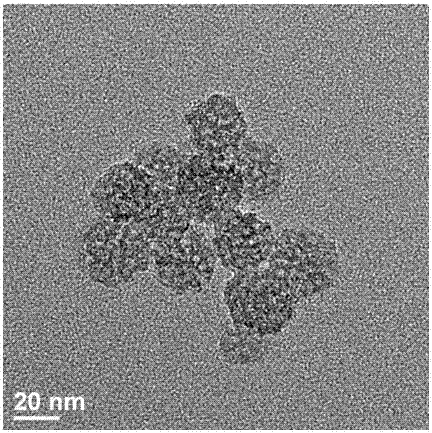

Embodiment 1

[0017] First, add 1.05g cetyltrimethylammonium bromide (CTAB) to 69.12ml deionized water, 6.2g sodium methoxide (CH 3 ONa), 0.238g triethanolamine (TEAH 3 In the beaker of ), stir at 80°C for 1 hour until the solution becomes clear, then add 10g of tetraethoxysilicate (TEOS) dropwise into the beaker, and continue to stir at 80°C for 2 hours to obtain a white precipitate. The molar composition of the mixture is SiO 2 :CTAB:TEAH 3 :H 2 O: CH 3 ONa = 1:0.06:0.026:80:0. 1; the obtained mixture is directly filtered, washed, and dried to obtain mesoporous SiO 2 Nano particles, the yield is 94%, and the average particle size is 31nm. The method of high temperature roasting or acid treatment can be used to remove the surfactant in the pores in one step. The specific methods are as follows: (1) 1.0g raw powder is directly roasted in a muffle furnace at 550°C for 6 hours; (2) 1.0g raw powder is in 40ml 1M In the hydrochloric acid ethanol solution, stirred at room temperature for 1 hour, f...

Embodiment 2

[0019] First, 1.05g cetyltrimethylpara-methylammonium bromide (CTAB) was added to 69.12ml deionized water, 0.123g sodium methoxide, 2.38g triethanolamine (TEAH 3 In the beaker of ), stir at 80°C for 1 hour until the solution becomes clear, then add 10g of tetraethoxysilicate (TEOS) dropwise into the beaker, and continue to stir at 80°C for 2 hours to obtain a white precipitate. The molar composition of the mixture is SiO 2 :CTAB:TEAH 3 :H 2 O: CH 3 ONa = 1:0.06:0. 26:80:0.002; the obtained mixture is directly filtered, washed, and dried to obtain mesoporous SiO 2 Nano particles, the yield is 95%, and the average particle size is 42nm. Change CH 3 With the molar ratio of ONa, mesoporous silica nanoparticles of different particle sizes can be obtained.

Embodiment 3

[0021] First, add 1.05g cetyltrimethyl-p-methylammonium bromide (CTAB) to 248.83ml deionized water, 0.123g sodium methoxide, 0.238g triethanolamine (TEAH 3 In the beaker of ), stir at 80°C for 1 hour until the solution becomes clear, then add 10g of tetraethoxysilicate (TEOS) dropwise into the beaker, and continue to stir at 80°C for 2 hours to obtain a white precipitate. The molar composition of the mixture is SiO 2 :CTAB:TEAH 3 :H 2 O: CH 3 ONa = 1:0.06:0.026:288:0.002; the obtained mixture is directly filtered, washed, and dried to obtain mesoporous SiO 2 Nano particles, the yield is 95%, and the average particle size is 25 nm. Increasing the water ratio and the amount of sodium methoxide can also reduce the particle size.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com