Aluminum-based composite hydrogen manufacturing material and preparation method thereof

An aluminum-based composite and raw material technology, applied in the energy field, can solve the problems of low maximum hydrogen production rate and achieve the effects of reducing storage costs, increasing specific surface area, and high activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Load the sample in the glove box, under the protection of argon, put 150g of steel balls and 5g of raw materials into the ball mill tank at a ratio of 30:1; Composite hydrogen production material; the raw materials are: Al and SnCl 2 Mix in different mass ratios shown in Table 1.

[0044] Table 1. Al-SnCl 2 mixed in different mass ratios

[0045]

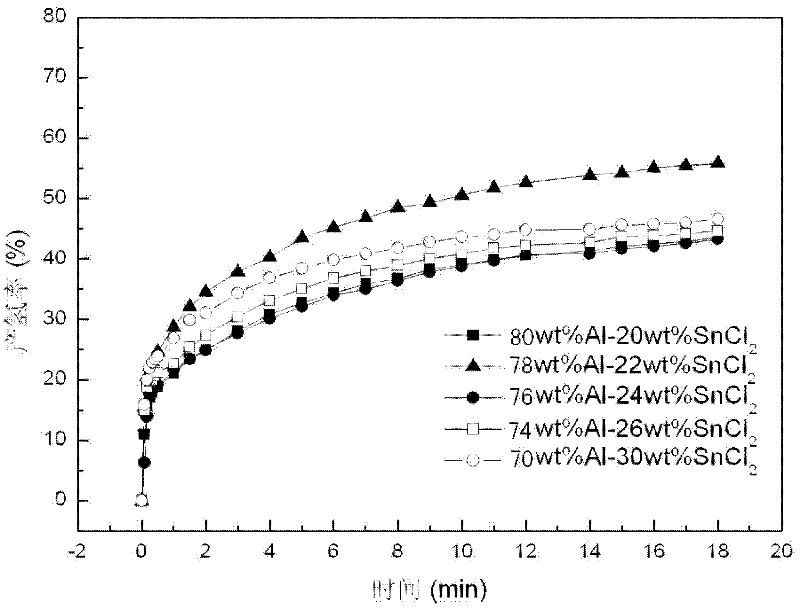

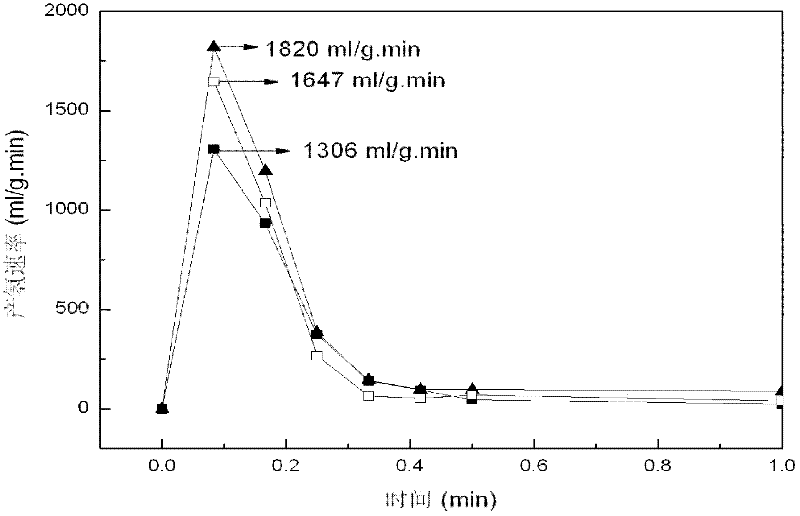

[0046] React the prepared different composite hydrogen production materials with water at room temperature, that is, weigh about 0.1g of composite hydrogen production materials, add 10ml of water, and measure their hydrogen production performance. The results are shown in Figure 1a and Figure 1b .

[0047] Figure 1a Al-SnCl of different mass ratio 2 The hydrogen production rate curve of the aluminum-based composite hydrogen production material reacting with water at room temperature, in which the volume of hydrogen is converted to the volume at 273.15K. The results show that: when SnCl 2 When the contents of the c...

Embodiment 2

[0051] Load the sample in the glove box, and under the protection of argon, put 150g of steel balls and 5g of raw materials into the ball mill tank at a ratio of 30:1; the ball milling speed is set to 450r / min, and the ball milling time is 1h , 2h, 3h and 4h, prepare different composite hydrogen production materials; the raw materials are: 78wt% Al and 22wt% SnCl 2 mix.

[0052] React the prepared different composite hydrogen production materials with water at room temperature, that is, weigh about 0.1g of composite hydrogen production materials, add 10ml of water, and measure their hydrogen production performance. The results are shown in Figure 2a and Figure 2b , the volume of hydrogen in the figure is converted to the volume at 273.15K.

[0053] Figure 2a and Figure 2b The results shown show that: when the ball milling time is 1h, 2h, 3h and 4h, the hydrogen production rates of the obtained composite hydrogen production materials are 29.3%, 39.6%, 55.9% and 45.1%, r...

Embodiment 3

[0055] Load the sample in the glove box, under the protection of argon, put 150g of steel balls and 5g of raw materials into the ball mill tank at a ratio of 30:1; the ball milling speed is set to 450r / min, and the ball milling time is 3h , to prepare different composite hydrogen production materials;

[0056] The raw materials are: 1) 78wt% Al and 22wt% SnCl 2 mixed; or

[0057] 2) 78wt% Al, 14wt% Sn and 8wt% AlCl 3 mix.

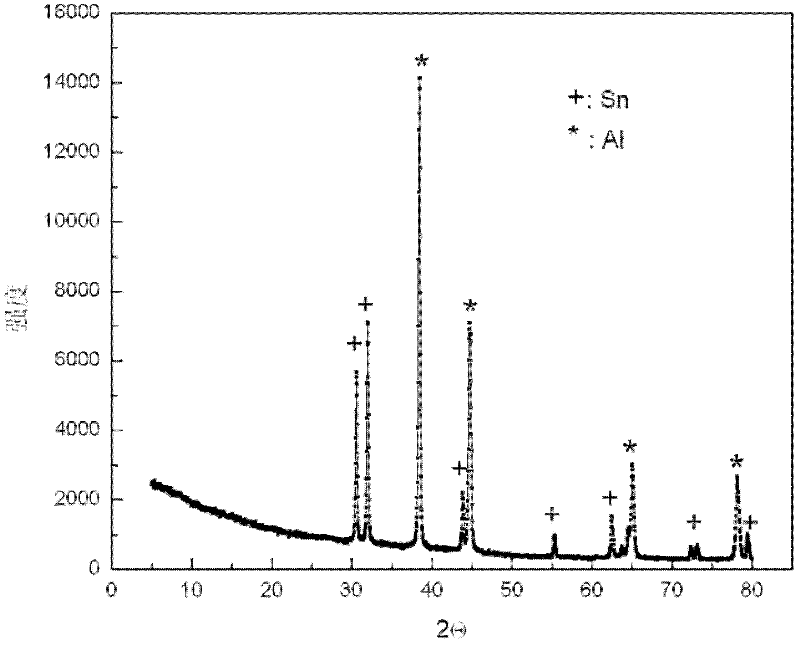

[0058] React the prepared different composite hydrogen production materials with water at room temperature, that is, weigh about 0.1g of composite hydrogen production materials, add 10ml of water, and measure their hydrogen production performance. The results are shown in Figure 3a and Figure 3b . The volume of hydrogen in the figure is converted to the volume at 273.15K.

[0059] Such as Figure 3a and Figure 3b Shown: Al, Sn and AlCl 3 The hydrogen production rate and hydrogen production rate of the composite hydrogen production material obtai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com