Self-repairing polyurethane elastomer based on multiple dynamic reversible effects, and preparation method thereof

A polyurethane elastomer, self-healing technology, applied in the field of functional polyurethane, can solve problems such as harsh conditions, and achieve the effects of improving mechanical strength, high self-healing efficiency, and mild self-healing conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

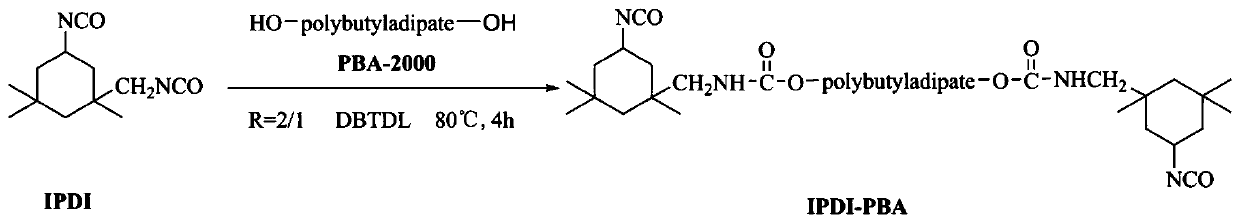

[0038]A method for preparing a self-healing polyurethane elastomer based on multiple dynamic reversible actions, comprising the following process steps:

[0039] Step 1, mix and stir 4.44g isophorone diisocyanate (IPDI) and 20.00g polybutylene adipate (PBA) 2000 evenly, add 0.1g dibutyltin dilaurate in a water bath with a temperature of 80°C Heated and stirred for 4 hours to obtain a prepolymer;

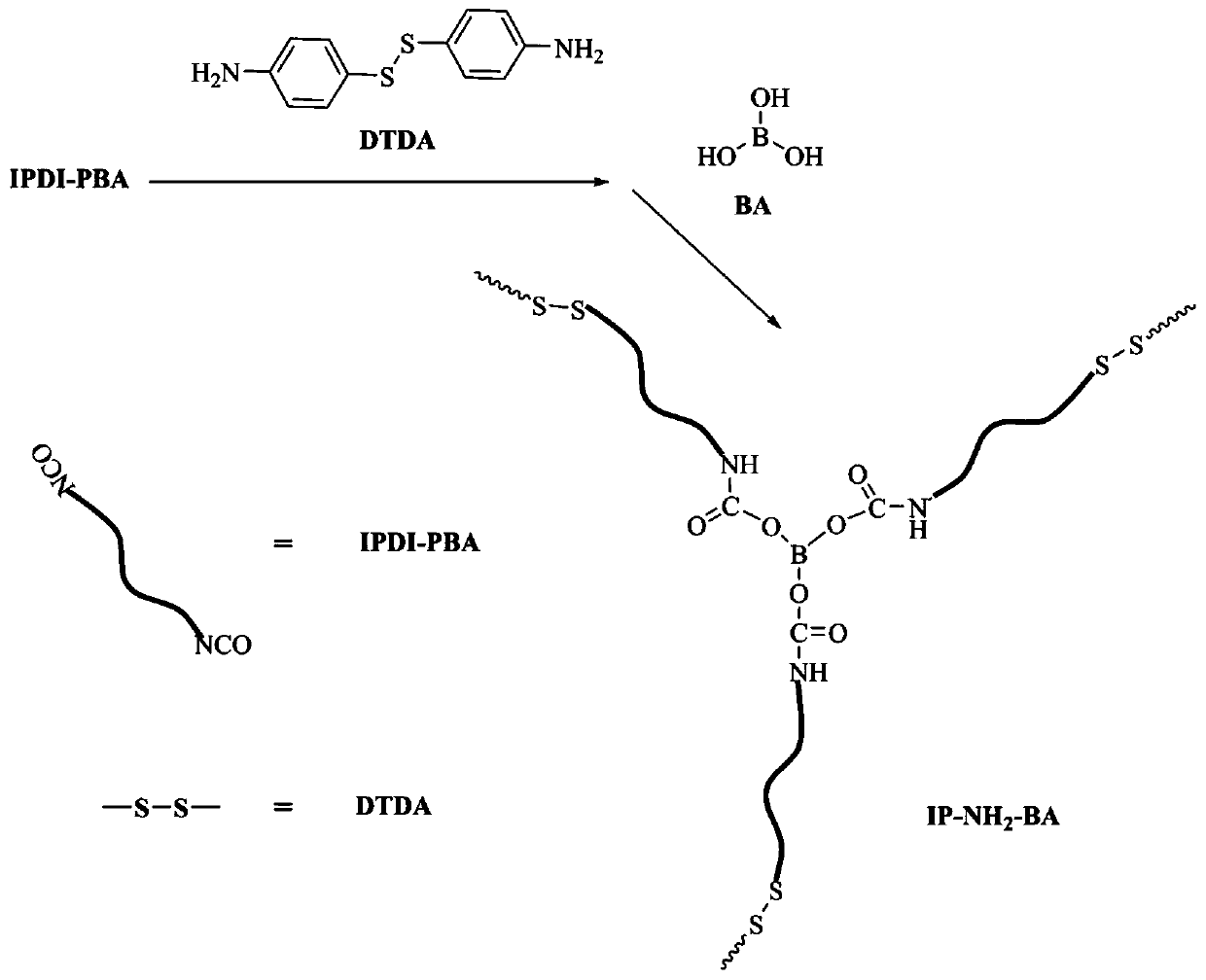

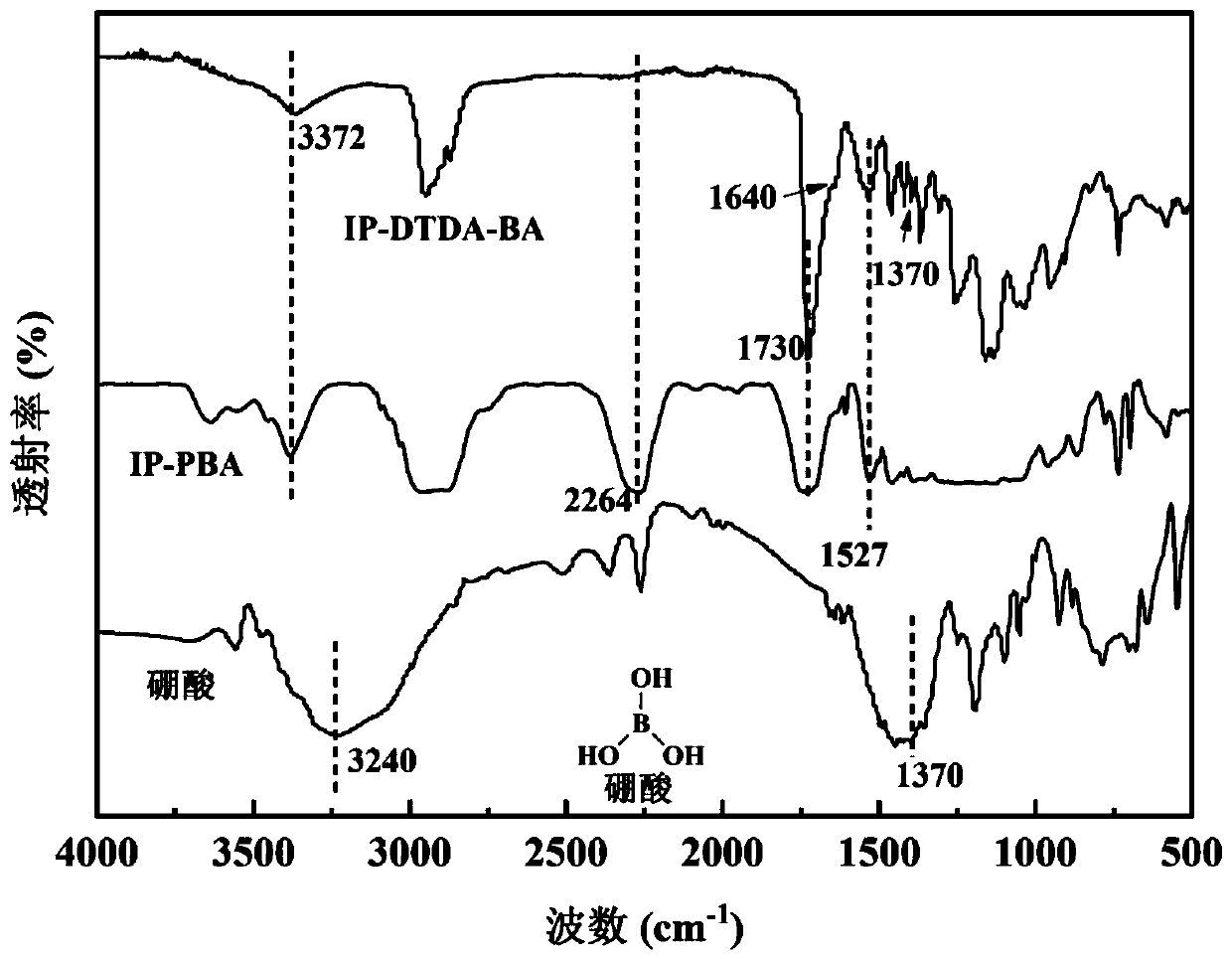

[0040] Step 2: Add 1.24g of 4,4'-diaminodiphenyl disulfide (DTDA) into the prepolymer, react at 80°C for 1 hour, and dilute with 10ml of acetone during this period to prevent gelation;

[0041] Step 3, add 0.44g boric acid into the prepolymer, stop heating and stir for 15min:

[0042] Step 4: After the product obtained in step 3 is mixed and stirred evenly, it is poured into a mold, vacuum defoamed, solidified and formed at 60°C, kept for 1d, and vacuum-dried at 80°C for 24h to constant weight to obtain a self- Repair polyurethane elastomers.

[0043] figure 1 A flow chart for pr...

Embodiment 2

[0048] A method for preparing a self-healing polyurethane elastomer based on multiple dynamic reversible actions, comprising the following process steps:

[0049] Step 1, 3.48g of toluene diisocyanate (TDI) and 20.00g of polybutylene adipate (PBA) 2000 were mixed and stirred evenly, and 0.05g of stannous octoate was added and heated and stirred in a water bath at a temperature of 70°C for 3 hours. get prepolymer;

[0050] Step 2: Add 1.24g of 4,4'-diaminodiphenyl disulfide (DTDA) into the prepolymer, react at 70°C for 1 hour, and dilute with 10ml of N,N-dimethylacetamide during this period to prevent gelation;

[0051] Step 3, add 0.44g boric acid into the prepolymer, stop heating and stir for 10min:

[0052] Step 4: After the product obtained in step 3 is mixed and stirred evenly, it is poured into a mold, vacuum defoamed, solidified and formed at 60°C, kept for 1d, and vacuum-dried at 70°C for 16h to constant weight to obtain a self- Repair polyurethane elastomers.

Embodiment 3

[0054] A method for preparing a self-healing polyurethane elastomer based on multiple dynamic reversible actions, comprising the following process steps:

[0055] Step 1, mix 3.36g 1,6-hexamethylene diisocyanate (HDI) and 20.00g polybutylene adipate (PBA) 2000 and stir evenly, add 0.07g dibutyltin dilaurate at a temperature of 70°C heated and stirred in a water bath for 3 hours to obtain a prepolymer;

[0056] Step 2: Add 1.24g of 4,4'-diaminodiphenyl disulfide (DTDA) into the prepolymer, react at 70°C for 1 hour, and dilute with 10ml of N,N-dimethylformamide during this period to prevent gelation;

[0057] Step 3, add 0.44g boric acid into the prepolymer, stop heating and stir for 10min:

[0058] Step 4: After the product obtained in step 3 is mixed and stirred evenly, it is poured into a mold, vacuum defoamed, solidified and formed at 60°C, kept for 1d, and vacuum-dried at 70°C for 16h to constant weight to obtain a self- Repair polyurethane elastomers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com