Production and processing process of intestinal membrane albumen powder

A technology of intestinal membrane protein powder and processing technology, which is applied in animal feed, animal husbandry, application, etc., can solve the problems of not being suitable for industrialized large-scale production, increasing the cost of drying, and complicated hydrolysis steps, so as to enhance production performance and health level, increase feed conversion rate, increase serum immunoglobulin concentration and effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

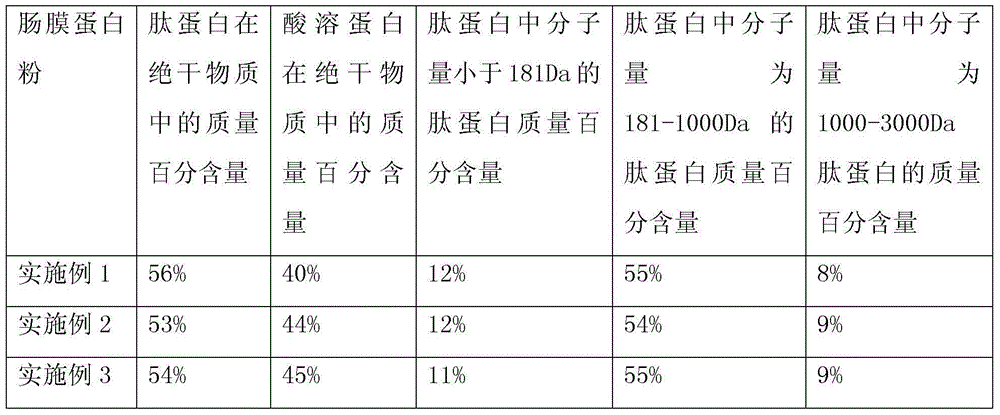

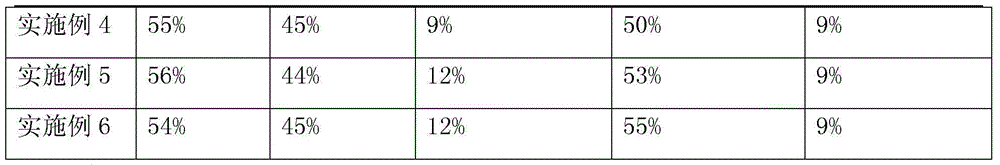

Embodiment 1

[0040] Weigh 1000 kg of intestinal residue after extracting heparin from pig intestinal mucosa, add 150 kg of water, and stir at 25° C. at a speed of 80 rpm for 40 minutes to obtain a mixture of intestinal residue and water. Add 5 kg of alkaline protease to the mixture of intestinal residue and water, raise the temperature to 40°C, add solid sodium hydroxide powder to adjust the pH to 9.0, mix well, and keep it warm at 40°C for 4 hours to obtain a hydrolyzate. The hydrolyzate is spray-dried to obtain intestinal membrane protein powder.

Embodiment 2

[0042] Weigh 1000 kg of intestinal residue after extracting heparin from pig intestinal mucosa, add 200 kg of water, and stir at 150 rpm for 20 minutes at 37° C. to obtain a mixture of intestinal residue and water. Add 0.5kg of alkaline protease to the mixture of intestinal residue and water, raise the temperature to 55°C, add solid sodium hydroxide powder to adjust the pH to 10.0, mix well, and keep it warm at 55°C for 2 hours to obtain a hydrolyzate. The hydrolyzate is spray-dried to obtain intestinal membrane protein powder.

Embodiment 3

[0044] Weigh 1000 kg of intestinal residue after extracting heparin from pig intestinal mucosa, add 250 kg of water, and stir at 100 rpm for 30 minutes at 40°C to obtain a mixture of intestinal residue and water. Add 10kg of alkaline protease to the mixture of intestinal residue and water, raise the temperature to 60°C, add solid sodium hydroxide powder to adjust the pH to 11.0, mix well, and keep it warm at 60°C for 1 hour to obtain a hydrolyzate. The hydrolyzate is spray-dried to obtain intestinal membrane protein powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com