Epoxy low temperature curable powder paint and preparation method thereof

A powder coating, low temperature technology, applied in the field of coatings, can solve the problems of poor leveling, easy pinholes on the surface of the coating film, unsightly appearance, etc., to improve the powder coating rate on the corners, excellent chemical corrosion resistance and electrical Good insulation performance and surface gloss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

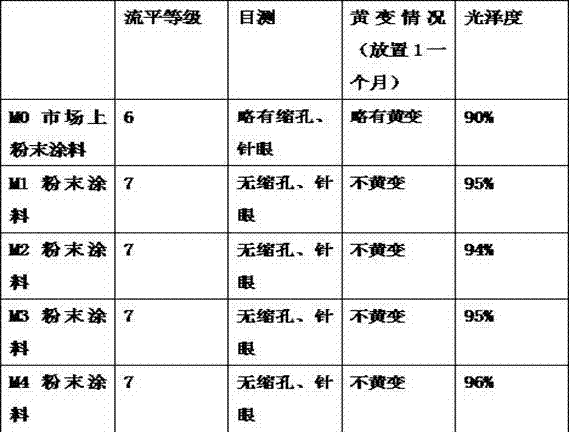

Examples

Embodiment 1

[0037] A kind of epoxy low-temperature curing powder coating, is made up of following parts by weight:

[0038] 35 parts of epoxy resin;

[0039] 20 parts of precipitated barium sulfate and active silica fume filler;

[0040] 0.05 parts of benzyltriethylammonium chloride;

[0041] 5 parts of inorganic pigments;

[0042] 3.5 parts of curing agent;

[0043] 0.5 part of curing aid;

[0044] 1.5 parts of wetting agent;

[0045] Rosin 0.2 parts;

[0046] Other additives 0.5-3 parts. Other additives are composed of components: leveling agent, dispersing agent, brightening agent, degassing agent, antioxidant, leveling agent is carboxymethyl cellulose; dispersing agent is calcium stearate; brightening agent is acrylate Copolymer; degassing agent is modified silicone oil; antioxidant is 2,6-tertiary butyl-4-methylphenol.

[0047] The epoxy resin is a hydrogenated bisphenol A type epoxy resin.

[0048] The wetting agent is selected from pull open powder BX.

Embodiment 2

[0050] A kind of epoxy low-temperature curing powder coating, is made up of following parts by weight:

[0051] 50 parts of epoxy resin;

[0052] 30 parts of precipitated barium sulfate and active silica fume filler;

[0053] 0.5 parts of benzyltriethylammonium chloride;

[0054] 15 parts of inorganic pigments;

[0055] 5.5 parts of curing agent;

[0056] 1.5 parts of curing aid;

[0057] 2.5 parts of wetting agent;

[0058] Rosin 0.5 part;

[0059] 3 parts of other additives.

[0060] Other additives are composed of components: leveling agent, dispersant, brightening agent, degassing agent, antioxidant. The leveling agent is carboxymethyl cellulose; the dispersant is calcium stearate; the brightener is acrylic ester copolymer; the degassing agent is modified silicone oil; the antioxidant is 2,6-tertiary butyl-4- methyl phenol.

[0061] The epoxy resin is a hydrogenated bisphenol A type epoxy resin.

[0062] The wetting agent is selected from pull open powder BX.

Embodiment 3

[0064] A preparation method for medium density fiberboard powder coating, comprising the following steps:

[0065]P1 mixed, the epoxy resin disclosed in Example 1 and Example 2, precipitated barium sulfate and active silica fume powder filler, benzyl triethylammonium chloride, inorganic pigment, curing agent, curing aid, other auxiliary The agent is mixed according to the parts by weight. After the mixing is completed, it is fully stirred at 65°C-80°C, and the wetting agent is added according to the parts by weight while stirring, and the mixture is uniform;

[0066] P2 is melted, and after the mixing is completed, add rosin weighed in parts by weight and melt and extrude together;

[0067] P3 tableting, tableting while cooling;

[0068] P4 is pulverized, and the coating after P3 tableting is pulverized;

[0069] P5 is sieved and passed through a 160 mesh sieve.

[0070] During the P2 melting process, the melting temperature is set in a 3-stage gradient, melting at 110°C fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com