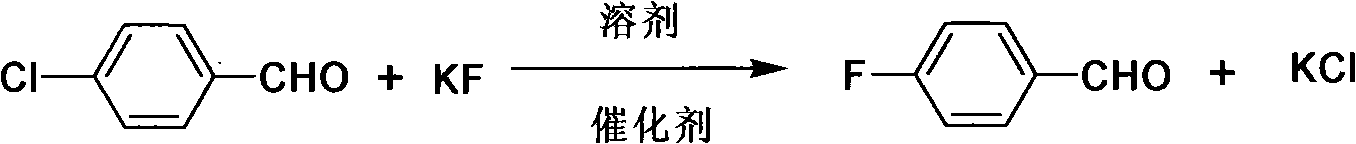

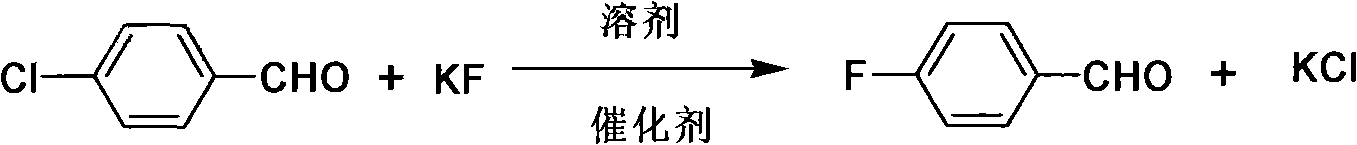

Synthetic method of 4-fluorobenzaldehyde

A technology for p-fluorobenzaldehyde and a synthesis method, which is applied in chemical instruments and methods, preparation of carbon-based compounds, preparation of organic compounds, etc., can solve the problems of high technical difficulty, complex process, and difficulty in obtaining cerium salts, and achieves a synthesis route. The effect of short, cheap, and cheap raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] In a 500ml autoclave, put 50g of p-chlorobenzaldehyde, 40g of anhydrous potassium fluoride, 5g of cetyltrimethylammonium chloride, and 250g of dimethylformamide, and then raise the temperature to 200°C for reaction. After the reaction is completed, the temperature is lowered and filtered, and the filtrate is first decompressed to recover the solvent dimethylformamide, and then the product is collected.

Embodiment 2

[0018] In a 500ml four-necked bottle, put 50g of p-chlorobenzaldehyde, 80g of anhydrous potassium fluoride, 5g of tetraphenylphosphonium bromide, and 200g of sulfolane, and then raise the temperature to 210°C for reaction. After the reaction is completed, filter, and the filtrate is first decompressed to obtain the product, and then the solvent sulfolane is recovered.

Embodiment 3

[0020] In a 500ml four-necked bottle, put 50g of p-chlorobenzaldehyde, 75g of anhydrous potassium fluoride, 4g of benzyltriphenylphosphonium bromide, 3g of polyethylene glycol dimethyl ether, and 300g of o-nitrotoluene, and then raise the temperature to 220°C reaction. After the reaction is completed, filter, and the filtrate is first decompressed to obtain the product, and then the solvent o-nitrotoluene is recovered.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com