Polyarylester-polydimethylsiloxane block copolymer modified polycarbonate and preparation method thereof

A polydimethylsiloxane and block copolymer technology, which is applied in the field of polyarylate-polydimethylsiloxane block copolymer modified polycarbonate and its preparation, can solve the problem of polycarbonate processing Reduced fluidity and other problems, to achieve good mechanical properties, excellent heat resistance and rigidity, and good lubricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

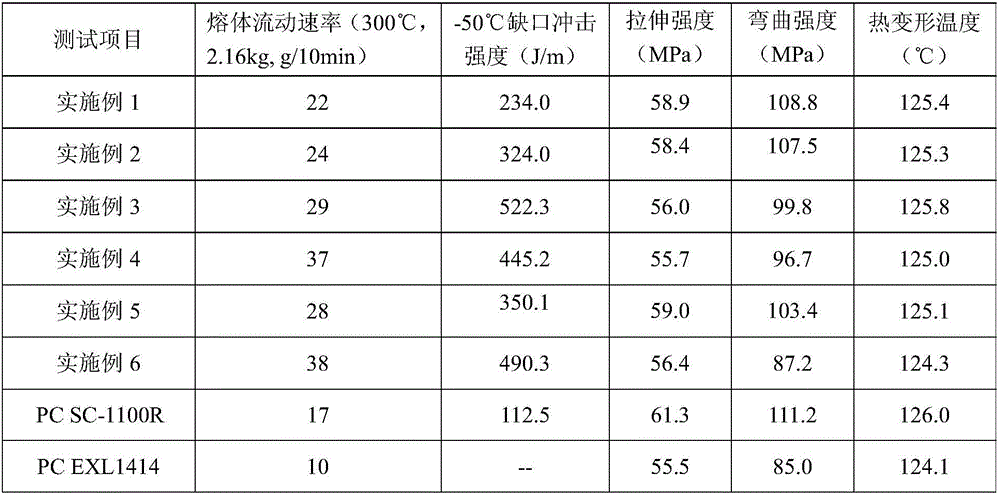

Examples

Embodiment 1

[0029] The preparation method of polyarylate-polydimethylsiloxane block copolymer: add 3.75mmol bisphenol A, 7.5mmol sodium hydroxide, and 5.0g deionized water into a three-necked flask equipped with mechanical stirring in sequence, and wait for two After phenol A is completely dissolved, add 0.035mmol benzyltriethylammonium chloride to form the aqueous phase; dissolve 4.2mmol isophthaloyl chloride in 20.0g dry dichloromethane to form the organic phase; The phase was slowly added dropwise into the water phase, and the dropping time was controlled to be 8 minutes. After the dropwise addition was completed, the reaction was stirred at 5°C for 60 minutes, the ice bath was removed, and 0.75mmol sodium hydroxide and 0.375mmol average Double-terminated amino polydimethylsiloxane with a molecular weight of 27000, reacted at room temperature for 5 hours to obtain a polyarylate-polydimethylsiloxane block copolymer emulsion; pour the emulsion into a separatory funnel, add The amount of ...

Embodiment 2

[0032]The preparation method of polyarylate-polydimethylsiloxane block copolymer: add 7.5mmol bisphenol A, 15.8mmol sodium hydroxide, and 16.0g deionized water into a three-necked flask equipped with mechanical stirring in sequence, and wait for two After phenol A is completely dissolved, add 0.080mmol benzyltriethylammonium chloride to form an aqueous phase; dissolve 7.95mmol isophthaloyl chloride in 30.0g dry dichloromethane to form an organic phase; phase was slowly added dropwise into the water phase, and the dropping time was controlled to be 15 minutes. After the dropping was completed, the reaction was stirred at 10°C for 40 minutes, and the ice bath was removed, and 1.76mmol sodium hydroxide and 0.84mmol average Double-terminated amino polydimethylsiloxane with a molecular weight of 27000, reacted at room temperature for 6 hours to obtain a polyarylate-polydimethylsiloxane block copolymer emulsion; pour the emulsion into a separatory funnel, add Deionized water, the am...

Embodiment 3

[0035] After mixing 947g polycarbonate, 50g polyarylate-polydimethylsiloxane block copolymer (PARSi2.7W-2) and 3g antioxidant 1098 in a high-speed mixer, pass through a twin-screw extruder Melt, knead, extrude, cool, pelletize and dry to obtain polyarylate-polydimethylsiloxane block copolymer modified polycarbonate pellets. The temperature of the extruder is set as: Zone 1 : 215°C, Zone 2 240°C, Zone 3-9: 260°C, Head: 260°C; Screw speed: 120r / min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com