Combined steel pipe pile for reducing wave force and seawater corrosion

A technology of seawater corrosion and steel pipe piles, which is applied in water conservancy projects, sea area projects, protection devices, etc., can solve the problems of weakening the bearing capacity of pile foundations, pile body fracture, and severe wave action, achieving significant economic benefits and reducing wave force , the effect of less steel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

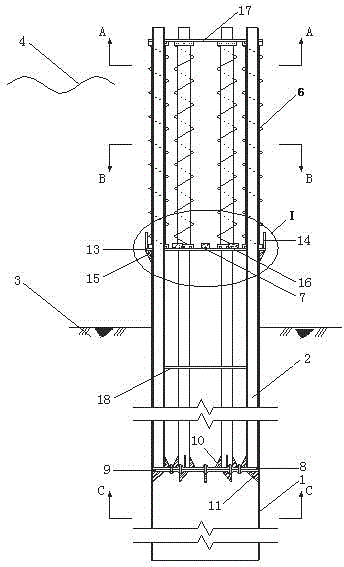

[0037] A project needs to set up pile foundations in an environment where the maximum wave height and water depth are 20m.

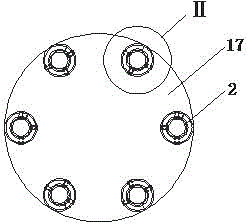

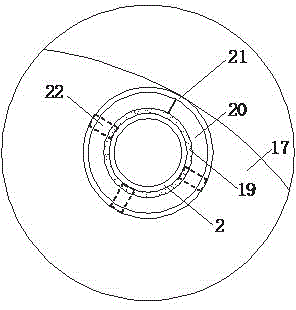

[0038]Large-diameter steel pipe piles 1 with an outer diameter of 2700mm and a wall thickness of 30mm are used. The top is 2m higher than the seabed, and the bottom is 60m below the seabed. The top of the large-diameter steel pipe pile 1 is welded with a reinforcing ring 13. The material of the reinforcing ring 13 is steel, with an inner diameter of 2700mm and an outer diameter of 3060mm. Sixteen ribs B15 are arranged at the junction of the outer wall of the pipe pile 1 . The rib plate B15 is made of a right-angled triangular steel plate with a thickness of 50mm, the side length of the side close to the large-diameter steel pipe pile 1 is 300mm, and the side length of the side close to the reinforcement ring 13 is 150mm.

[0039] The inside of the large-diameter steel pipe pile 1 is provided with an upper flange 8 and a lower flange 9 at 10 m from the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com