Offshore wind turbine single-pile foundation with internal sacrificial anode structure

A sacrificial anode, offshore fan technology, applied in infrastructure engineering, construction, etc., can solve the problems of many artificial welding points, large overall engineering volume, long processing cycle, etc., to reduce offshore construction operation time, obvious economic benefits, reduce The effect of hoisting costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

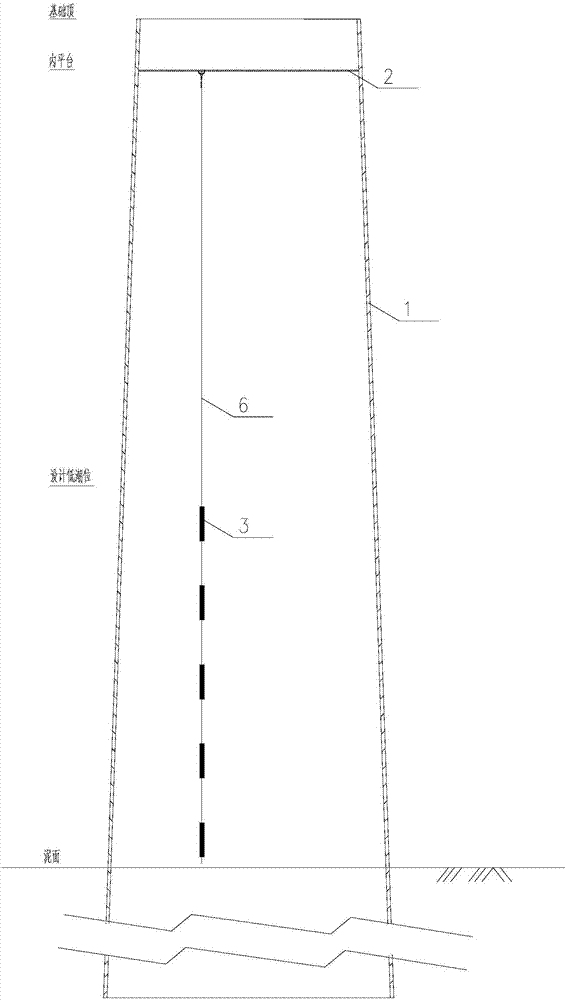

[0018] Such as figure 1 As shown, this embodiment is a single-pile foundation for offshore wind turbines with an internal sacrificial anode structure. The steel pipe pile 1 is provided with an inner platform 2 connected to the steel pipe piles. The inner platform is located 1.2- 1.5 meters away. The lower end surface of the inner platform 2 is evenly arranged with 4-6 strings of sacrificial anodes according to the protection area of the inner wall of the steel pipe pile 1.

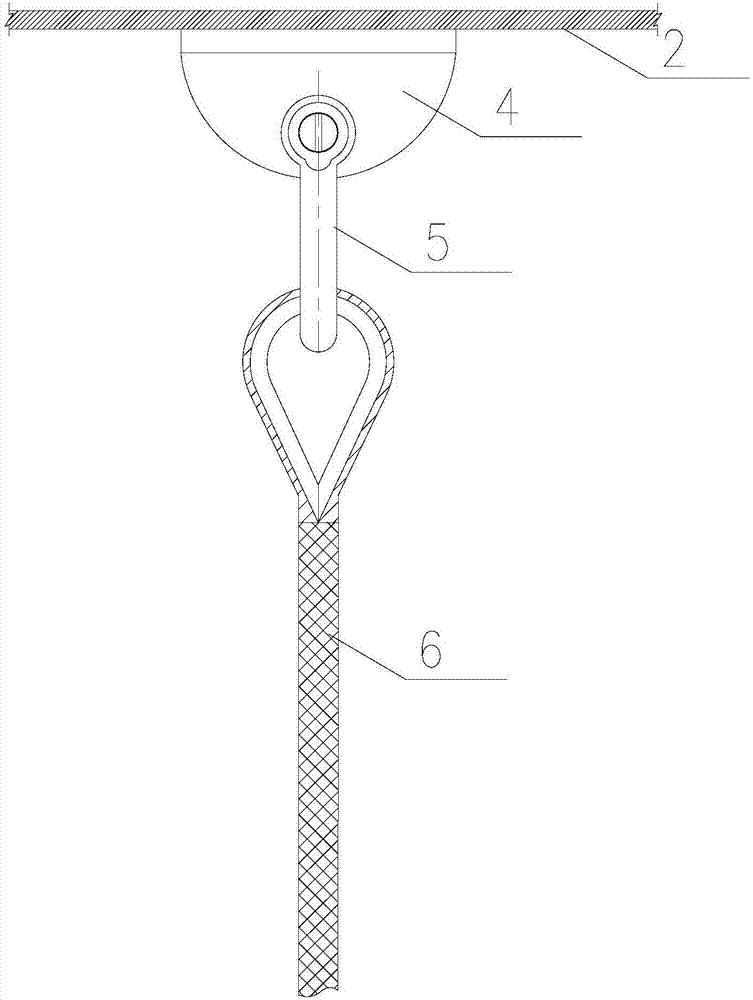

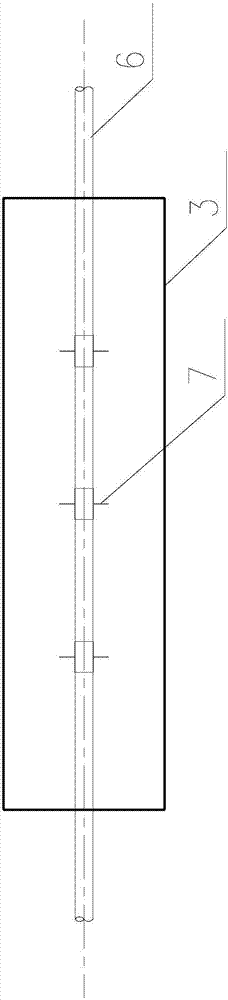

[0019] In the present embodiment, the sacrificial anode string includes a steel wire rope 6 and 5 sacrificial anodes 3 connected in series on the steel wire rope, wherein the upper end of the steel wire rope 6 is suspended on the lug 4 on the lower end surface of the inner platform 2 through a shackle 5 (see figure 2 ), the lower end of the wire rope 6 extends to the mud surface; the sacrificial anode 3 is fixed on the wire rope 6 through the snap ring 7 (see image 3 ), the sacrificial anode 3 is arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com