Corrosion test device and method for steel-concrete composite beam shear connectors

A technology for shear-resistant connectors and test devices, applied in measuring devices, weather resistance/light resistance/corrosion resistance, instruments, etc., can solve the problems of narrow application range, no test method, neglect of corrosion protection of steel beams, etc. wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0035] The following is a further description of the corrosion test method of the connectors in the steel-concrete composite beam in conjunction with the attached drawings:

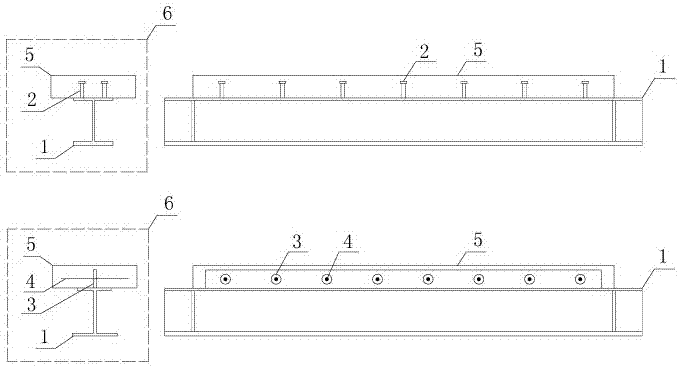

[0036] The test object of this embodiment is steel-concrete composite beam, its structure is as follows figure 1 As shown, a shear connector such as a stud connector 2 or a PBL connector 3 is welded on a steel beam 1 , and then concrete 5 is poured to form a wing plate to form a steel-concrete composite beam 6 . When the PBL connector 3 is used, a penetrating steel bar 4 is pierced thereon.

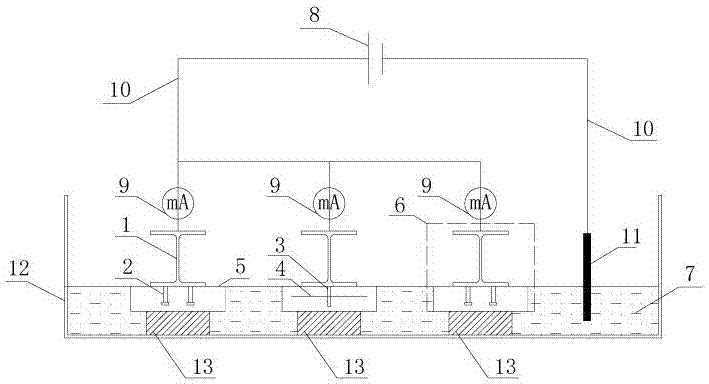

[0037] Such as figure 2 As shown, during the test, the shear connectors were welded on the steel beam, and then concrete 5 was poured to form a steel-concrete composite beam 6, and antirust paint was applied on the surface of the steel beam 1 and the interface with the wing plate. Pour the NaCl solution 7 with a certain concentration in the corrosion pool 12, then put a certain number of pads 13 in the pool, then ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com