Method for producing a steel component provided with a metallic coating providing protection against corrosion

A technology for anti-corrosion protection and steel components, applied in the direction of manufacturing tools, heat treatment equipment, process efficiency improvement, etc., can solve the problem that heating will not achieve layer characteristics, and achieve the effect of reducing moisture absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

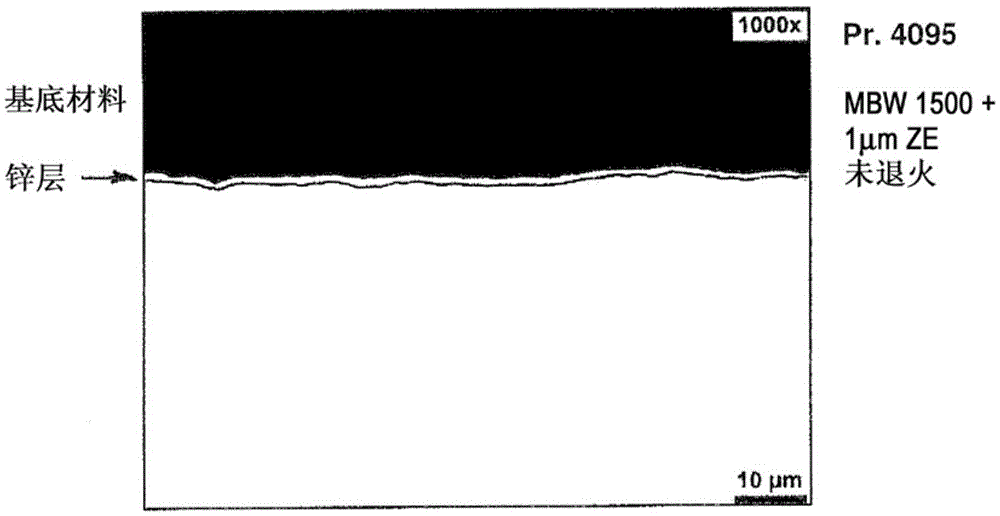

[0063] Annealed cold-rolled strips of steel grade 22MnB5 (1.5528) were degreased with alkaline jetting and additionally with electrolyte. The degreasing basin contains a concentration of about 15g / L of a commercially available cleaner with greater than 25% sodium hydroxide, 1-5% fatty alcohol ether, and 5-10% ethoxylated, acrylic acid Oxylated and methylated C12-18 alcohols. The cell temperature was approximately 65°C. The duration of jet degreasing is about 4-6 s. Followed by scrubbing. In the following process, the strips were electrolytically degreased with a residence time of about 3 s through the anode and cathode at a current density of 15 A / dm2. Subsequently, multi-stage rinsing was performed by using a brush with deionized water at room temperature. The duration during flushing is about 2-4s. Then pickling with hydrochloric acid (20 g / L; temperature 35-38° C.) was carried out with a residence time of about 10-12 s. After continuous rinsing by deionized water for ...

example 2

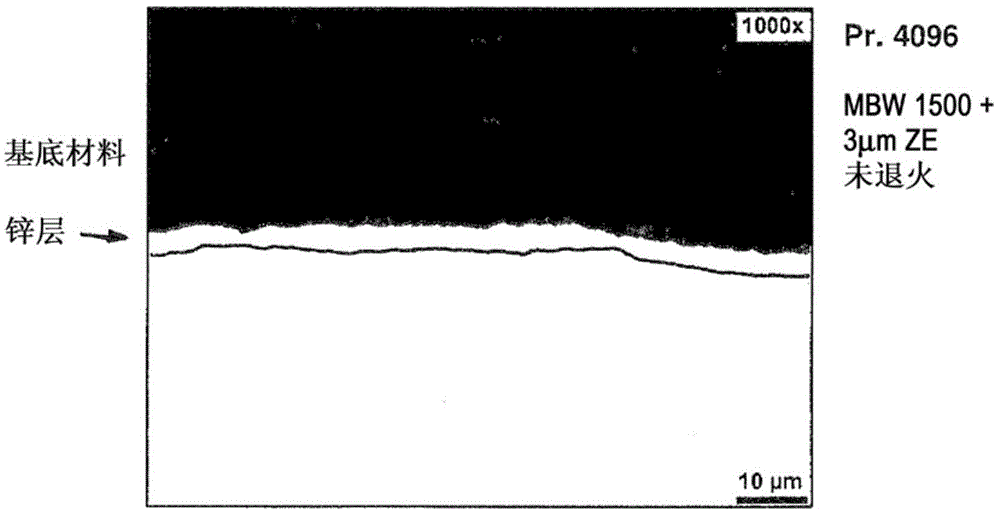

[0073]Hot-rolled strip (pickling) of steel grade 22MnB5 (1.5528) was degreased with alkaline spraying and degreased with electrolyte. The degreasing bath contains a concentration of 20g / L of detergent with greater than 1-5% C12-18 fatty alcohol polyglycol butyl ether and 0.5-2% potassium hydroxide. The cell temperature was approximately 75°C. The duration in the horizontal jet flush is about 10-12 s. Followed by double brushing. In the following process, the strip is electrolytically degreased with a residence time of about 8-10 s through the anode and cathode at a current density of 10 A / dm2. Subsequently, multi-stage rinsing was performed by using a brush with deionized water at room temperature. The duration is about 2-4s. This was followed by a hydrochloric acid pickling (100 g / L; room temperature) with a residence time of about 26-28 s. After combined brushing and fresh water spraying, the plates are transferred after passing through the extrusion device into a horiz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com