Method for obtaining uniform coating of crystallizer copper plate based on finite element simulation

A crystallizer copper plate and uniform coating technology, applied in the direction of design optimization/simulation, CAD numerical modeling, etc., can solve the problem of not obtaining the best shielding position of the shielding plate, so as to improve the plating efficiency and plating uniformity, and reduce the plating The time, the effect of improving the success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to better understand the technical content of the present invention, specific embodiments are given together with the attached drawings for description as follows.

[0037] Aspects of the invention are described in this disclosure with reference to the accompanying drawings, which show a number of illustrated embodiments. The embodiments of the present disclosure are not defined to encompass all aspects of the invention. It should be appreciated that the various concepts and embodiments described above, as well as those described in more detail below, can be implemented in any of numerous ways, since the concepts and embodiments disclosed herein are not limited to any implementation. In addition, some aspects of the present disclosure may be used alone or in any suitable combination with other aspects of the present disclosure.

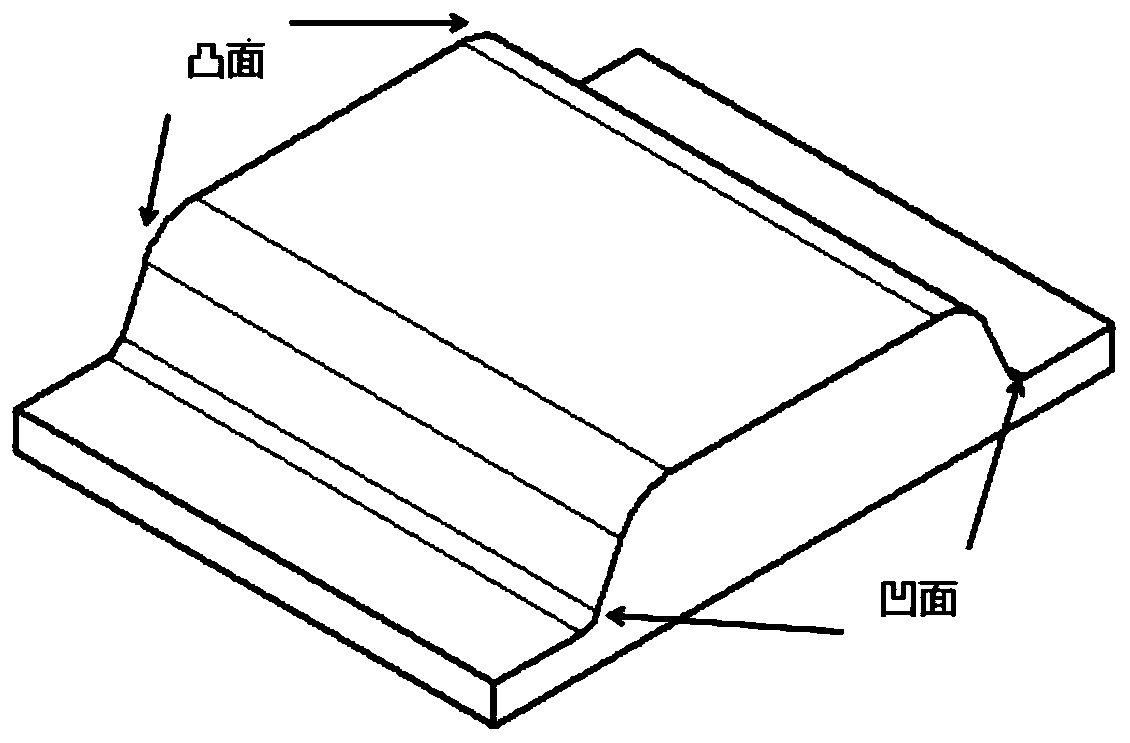

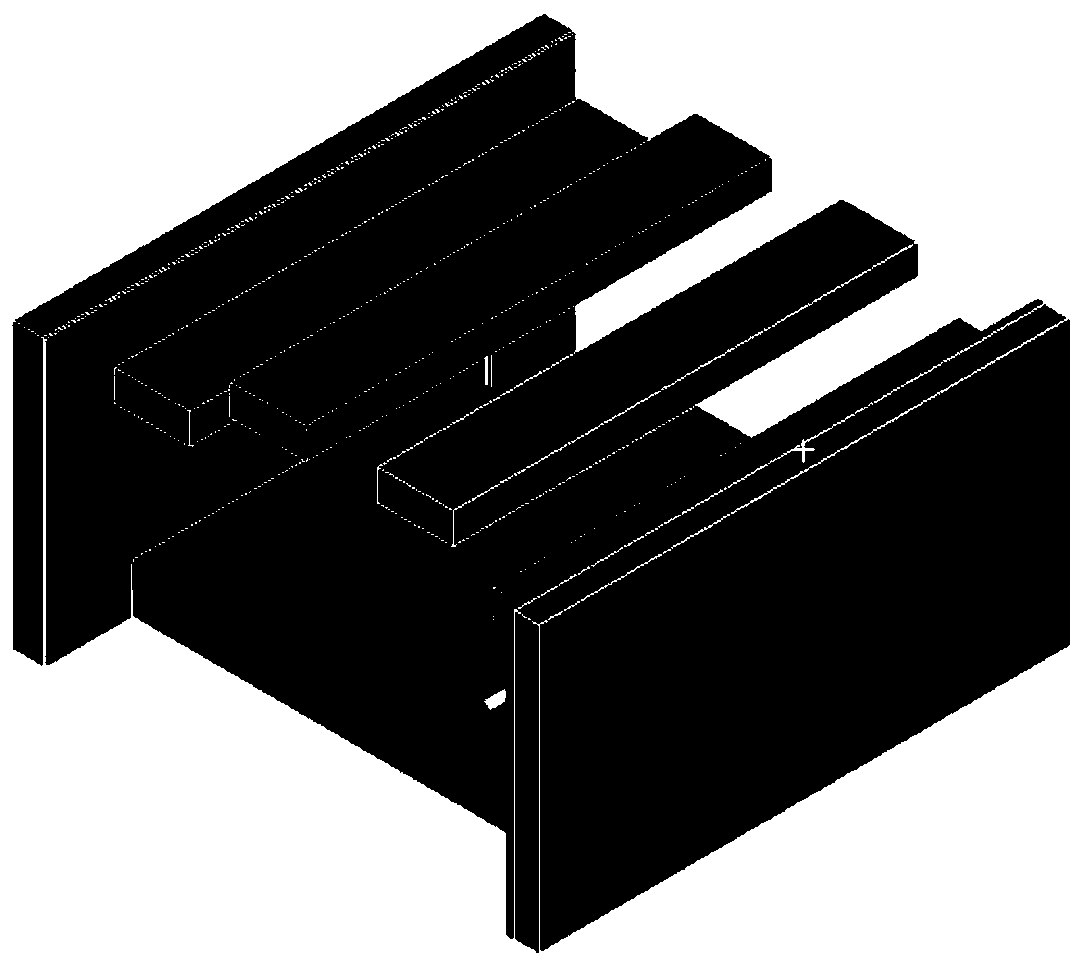

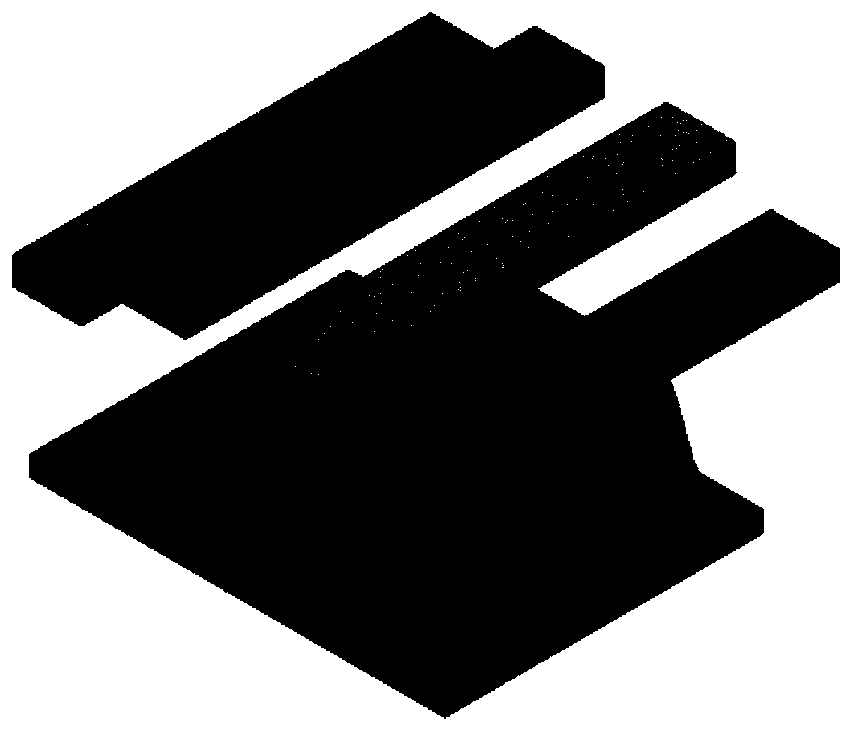

[0038] Based on the lack of shielding plates in the prior art, it may be applied to the electroplating process of the shaped billet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com