Sterilizing and pesticide-residue-reducing low-temperature plasma generator

A low-temperature plasma and generator technology, applied in the direction of plasma, electrical components, etc., can solve the problems of reducing the service life of plasma equipment, small double-electrode plasma processing capacity, and poor plasma penetration, and achieve stable work. , long service life, uniform discharge effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

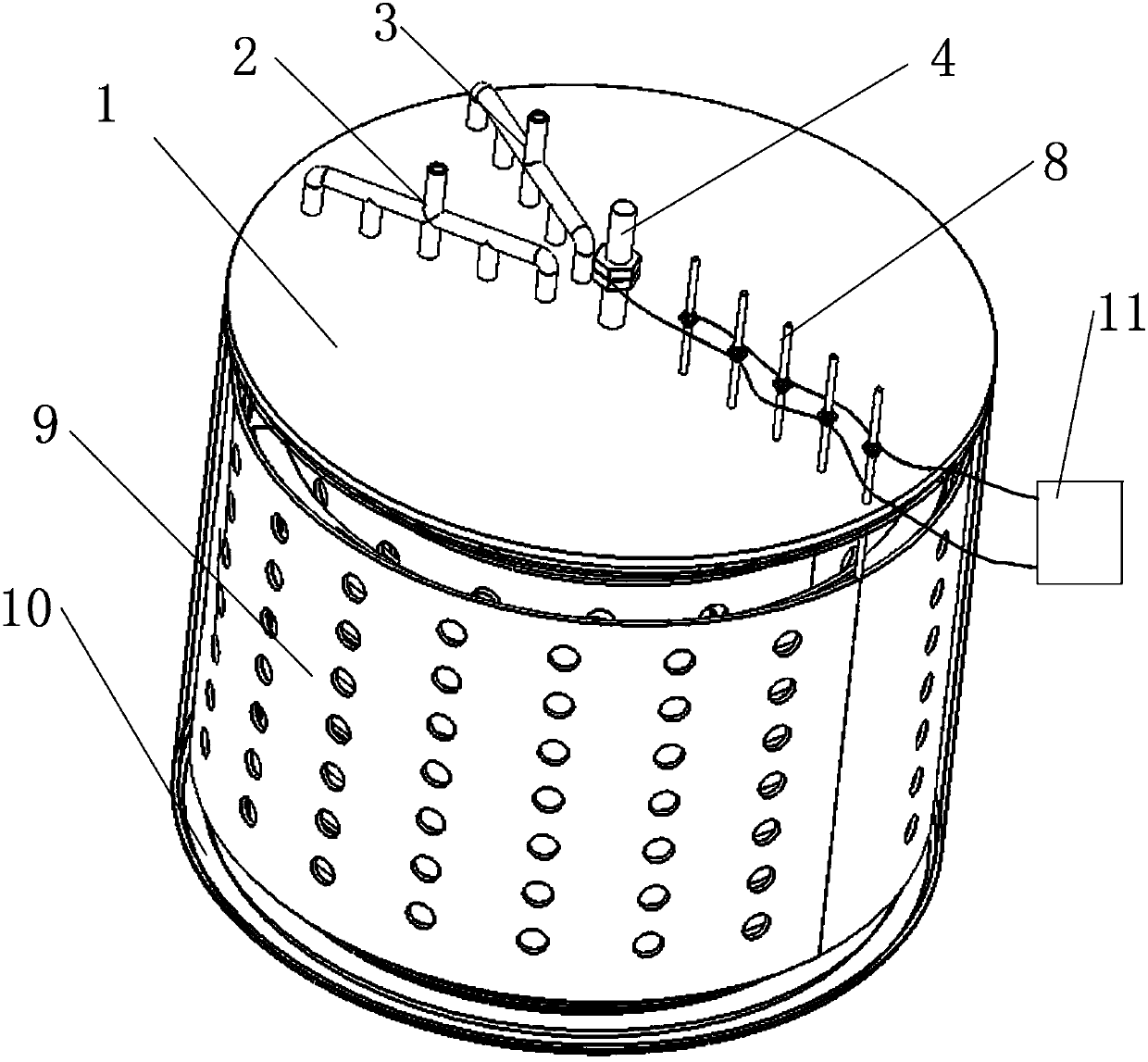

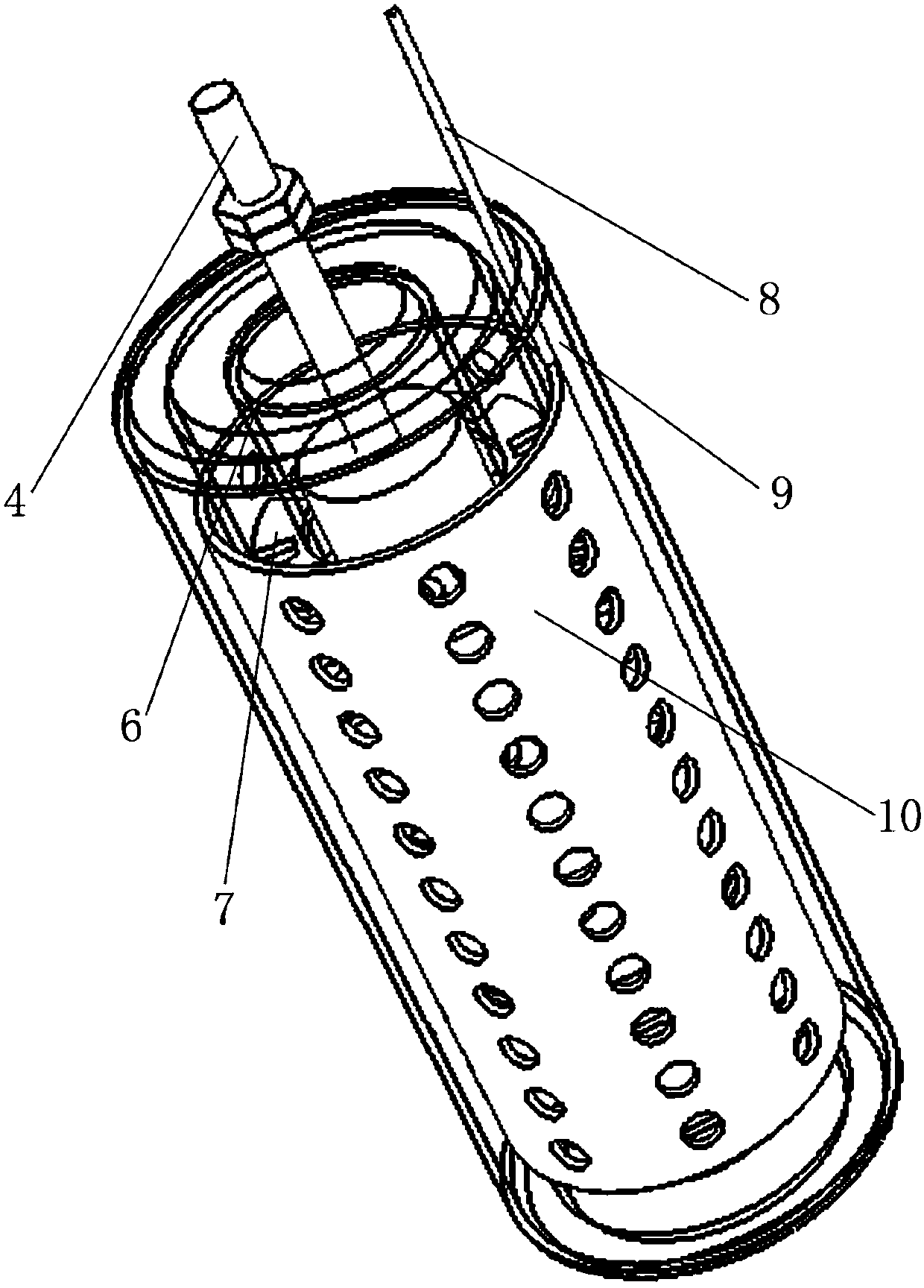

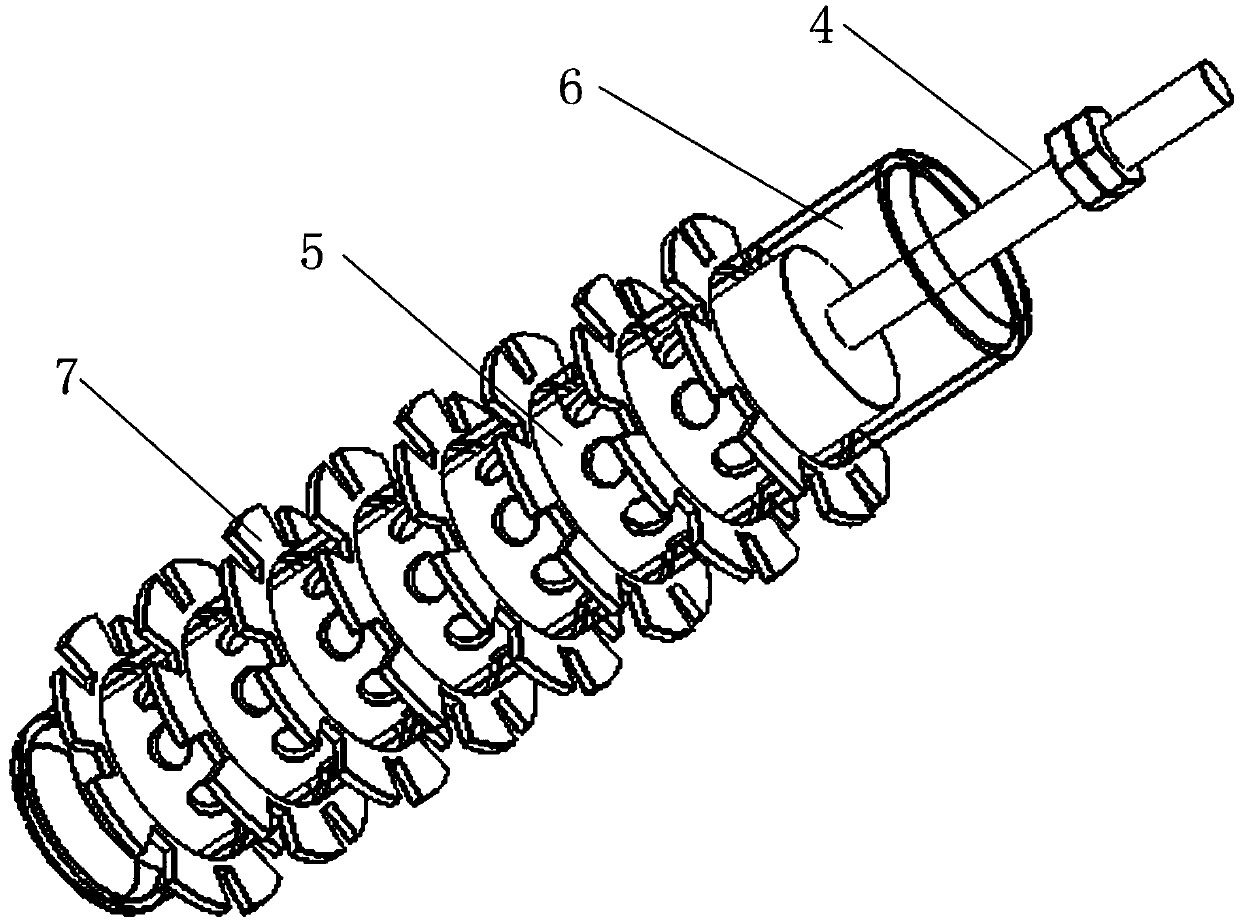

[0022] Such as Figure 1 to Figure 3 A low-temperature plasma generating device for sterilizing and reducing pesticide residues shown includes four parts, an inner tube electrode, a concentric outer tube electrode, a discharge chamber processing device, and a high-voltage power supply. The inner tube electrode is composed of an inner electrode lead wire 4, an inner The electrode tube 5 and the inner electrode glass tube 6 are composed; the concentric outer tube electrode is composed of 2-10 layers of concentric glass tubes with electrodes embedded inside. Here, the first layer of outer tube electrodes is described, and the first layer of outer tube electrodes consists of The lead wire 8, the outer electrode cylinder 9, and the outer electrode glass cylinder 10;

[0023] The inner electrode glass tube 6 is a closed glass tube with a tube height of 100 mm, an outer diameter of 10 mm, and a tube wall thickness of 0.5 mm. It is vacuumed or filled with mercury vapor or argon. The i...

Embodiment 2

[0030] Similar to Example 1, the concentric outer tube electrode is composed of 10 layers of concentric glass tubes with electrodes embedded in them. The inner electrode glass tubes are 200 mm high, 20 mm in outer diameter, and 1 mm in wall thickness. Mercury vapor is filled inside. The inner electrode tubes are 5 Made of copper, the concentric outer tube electrode is composed of 2-10 layers of concentric glass cylinders with electrodes embedded inside. The distance between the electrode cylinders is 10mm, the wall thickness of the glass tube is 1mm, the distance between the two glass tubes is 10mm, and mercury vapor is filled in the middle. , the distance between the outer circle of the inner electrode glass tube 6 and the inner circle of the outer electrode glass tube 10 is 10 mm. The liquid separator ring 7 is arranged vertically at intervals of 40mm in the inner electrode glass tube 6, the high-voltage power supply 11 has a frequency of 10,000 Hz, a voltage of 10,000 volts,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com