Method for on-line detection of surface defects of metal arc-shaped workpiece

A workpiece surface and detection method technology, applied in the field of computer vision, can solve the problems of indistinct background gray value distinction, difficult segmentation of defect areas, and many defect types, achieving good detection accuracy and robustness, reducing grayscale inconsistency. The effect of the average value, the obvious effect of the potential value contrast

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

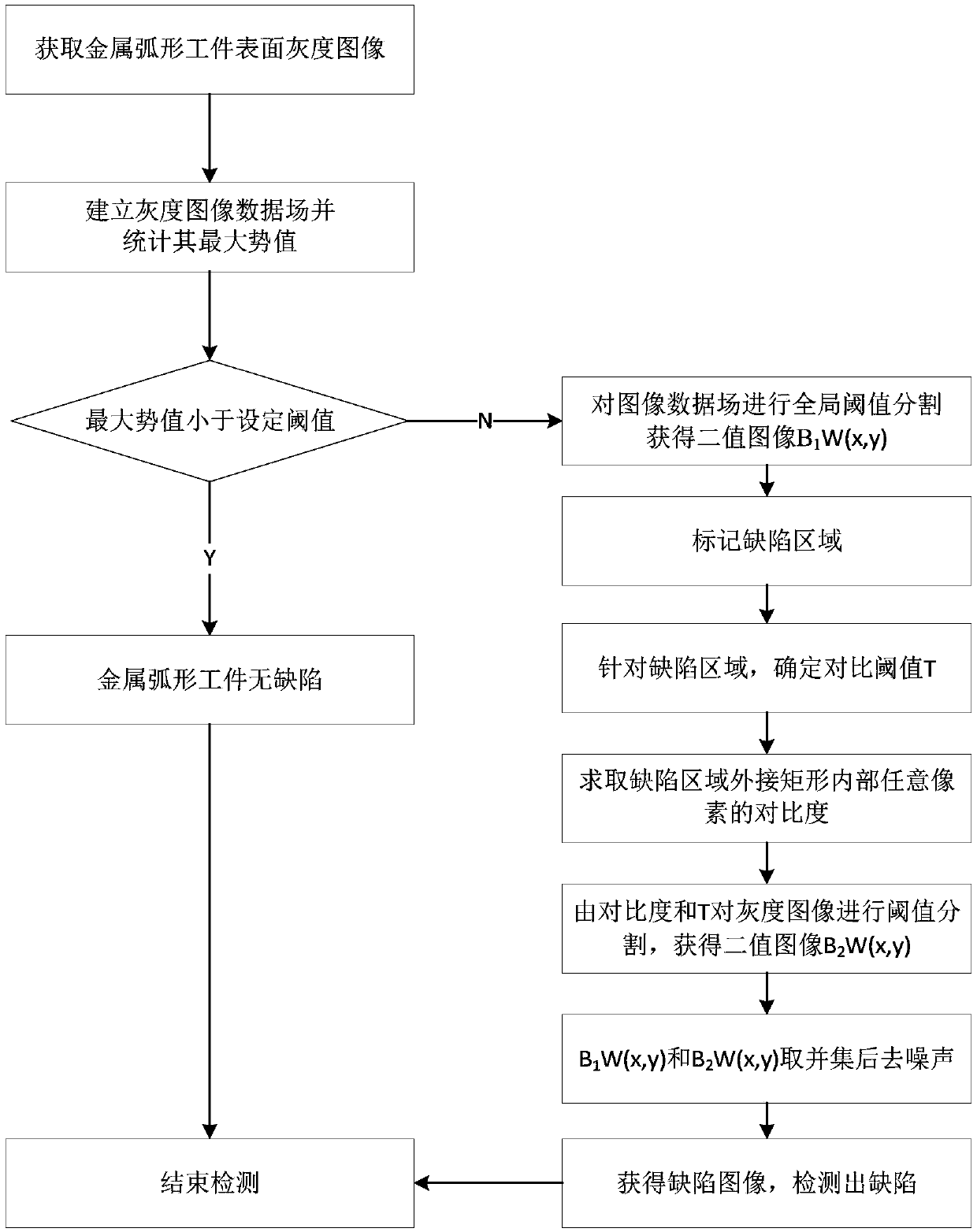

[0048] The online detection method for surface defects of metal arc-shaped workpieces in the embodiment of the present invention, the method includes:

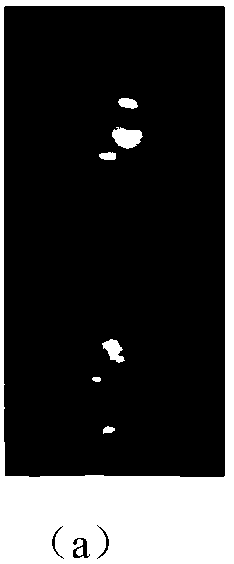

[0049] Step 1. Collect the surface image of the metal arc workpiece and convert it into a grayscale image, then establish the grayscale image data field, and count the maximum potential value of the data field. If the maximum potential value is less than the set threshold, the metal is judged If the arc-shaped workpiece has no defects, end the detection, otherwise go to step 2.

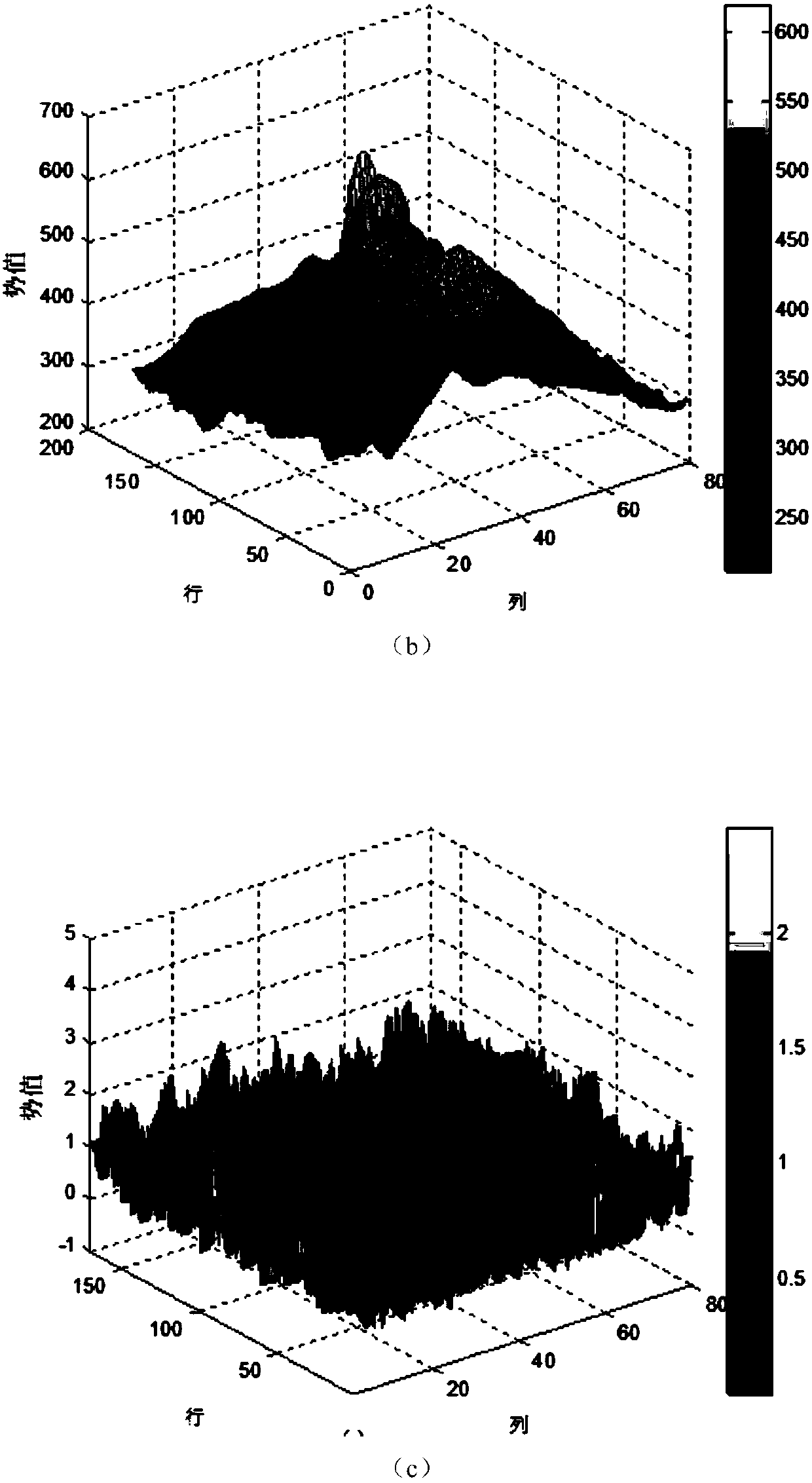

[0050] The established image data field is used to reflect the gray contrast between two pixels, and its expression is:

[0051]

[0052] In the formula, is the potential value generated by pixel point q at pixel point p, m q is the source strength of q, d p,q is the distance between q and p, σ d is an influencing factor that determines the range of action of pixel q.

[0053] At the same time, in order to make the potential value at the junc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com