Internal electrode for composite insulator and equalizing ring configuring method as well as composite insulator thereof

A technology of composite insulators and inner electrodes, applied in the direction of insulators, suspension/strain insulators, circuits, etc., can solve the problems of large size, difficult processing, low mechanical load capacity of mandrels, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The content of the present invention will be further described below in conjunction with the accompanying drawings and embodiments, but the production structure of the actual product of the present invention is not limited to the following embodiments.

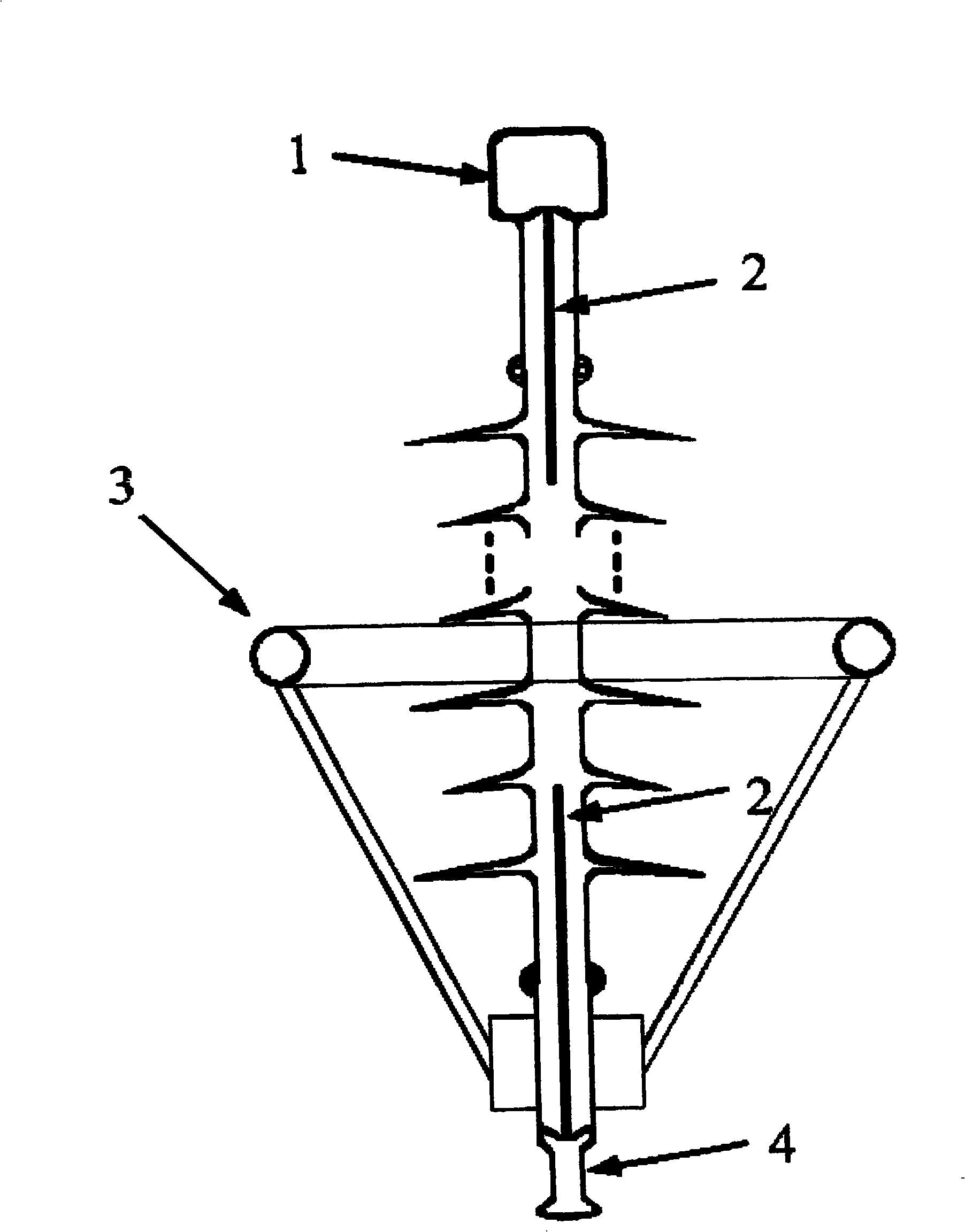

[0013] The configuration method of the present invention is: on the basis of manufacturing the composite insulator with the inner electrode 2, the voltage equalizing ring 3 is installed on the side of the high-voltage conductor of the composite insulator. The grading ring 3 has the same potential as the metal fitting (steel leg) 4 on the wire side of the composite insulator and the high-voltage wire, and a low electric field area is formed between the grading ring, the inner electrode on the wire side of the composite insulator, and the steel leg 4, which can effectively cover the steel The end surface electric field between the foot fitting 4 and the silicone rubber sheath also reduces the electric field intensity on th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com