Method for enhancing jet printing fastness in ink jet digital printing

A digital printing and ink technology, applied in ink, dyeing, textiles and papermaking, etc., can solve the problem that the washing fastness, dry and wet rubbing fastness cannot meet the requirements of clothing fabrics, dry rubbing and wet rubbing color fastness cannot meet the requirements, Waste of water resources and other issues, to achieve the effect of improving hand feel and color fastness, shortening the printing process, and protecting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

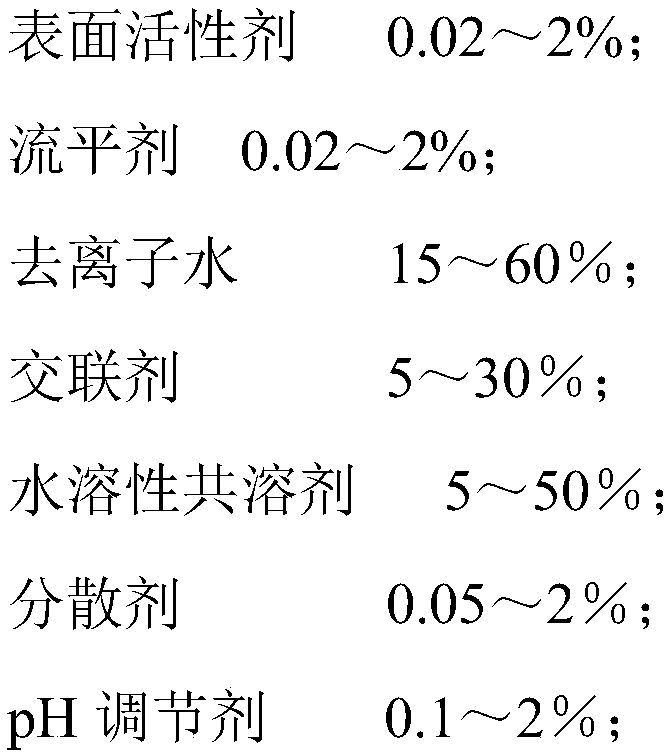

Method used

Image

Examples

Embodiment 1

[0027] A method for enhancing the printing fastness of ink in inkjet digital printing provided by this embodiment is characterized in that it at least includes the following steps:

[0028] In the first step, the water-based transparent paint ink is spray-printed to the position where the pattern needs to be printed on the fabric with a digital printing jet printer to form the first water-based transparent paint ink layer;

[0029] In the second step, the colored ink is spray-printed on the surface of the first water-based transparent paint ink layer with a digital printing jet printer to form a colored ink layer;

[0030] In the third step, the water-based transparent paint ink is spray-printed onto the surface of the colored ink layer with a digital printing jet printer to form a second water-based transparent paint ink layer;

[0031] In the fourth step, the fabric can be cured into a finished product after flash drying.

[0032] Wherein, the thickness of the first water-b...

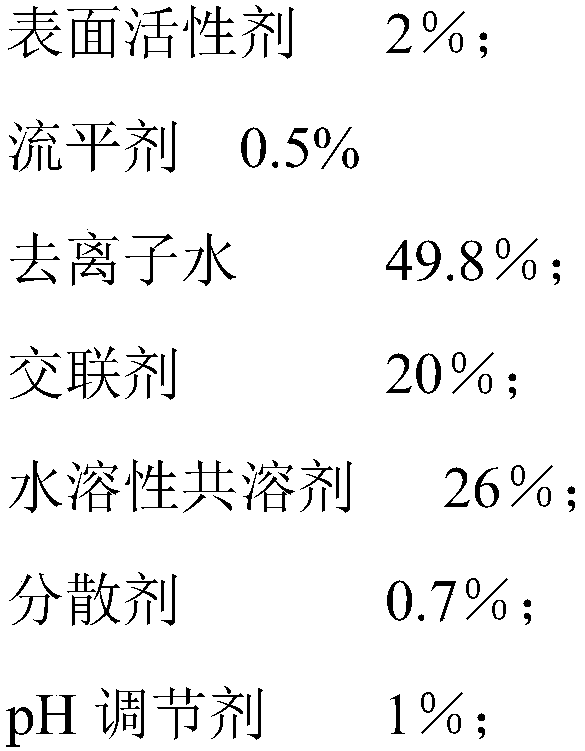

Embodiment 2

[0040] A method for enhancing the printing fastness of ink in inkjet digital printing provided by this embodiment is characterized in that it at least includes the following steps:

[0041] In the first step, the water-based transparent paint ink is spray-printed to the position where the pattern needs to be printed on the fabric with a digital printing jet printer to form the first water-based transparent paint ink layer;

[0042] In the second step, the colored ink is spray-printed on the surface of the first water-based transparent paint ink layer with a digital printing jet printer to form a colored ink layer;

[0043] In the third step, the water-based transparent paint ink is spray-printed onto the surface of the colored ink layer with a digital printing jet printer to form a second water-based transparent paint ink layer;

[0044] In the fourth step, the fabric can be cured into a finished product after natural drying.

[0045] Wherein, the thickness of the first water...

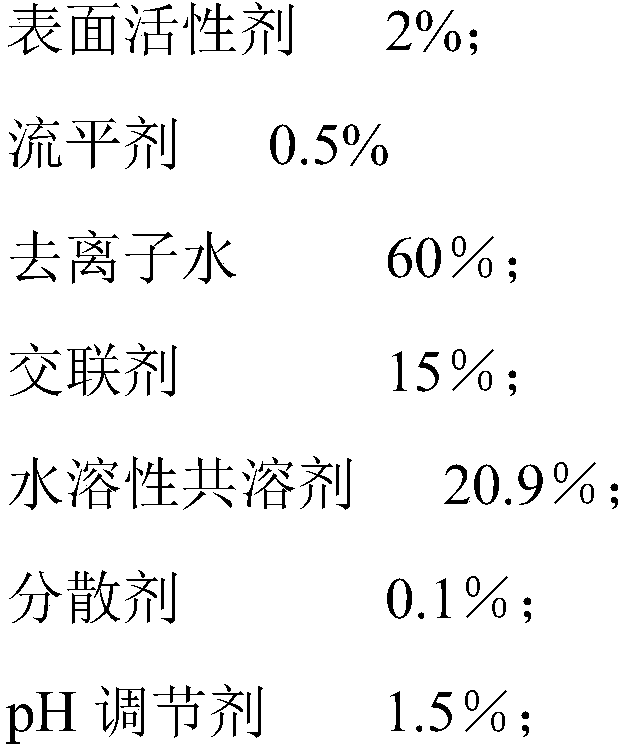

Embodiment 3

[0053] A method for enhancing the printing fastness of ink in inkjet digital printing provided by this embodiment is characterized in that it at least includes the following steps:

[0054] In the first step, the water-based transparent paint ink is spray-printed to the position where the pattern needs to be printed on the fabric with a digital printing jet printer to form the first water-based transparent paint ink layer;

[0055] In the second step, the colored ink is spray-printed on the surface of the first water-based transparent paint ink layer with a digital printing jet printer to form a colored ink layer;

[0056] In the third step, the water-based transparent paint ink is spray-printed onto the surface of the colored ink layer with a digital printing jet printer to form a second water-based transparent paint ink layer;

[0057] In the fourth step, the fabric can be cured into a finished product after flash drying.

[0058] Wherein, the thickness of the first water-b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com