Preparation method for patterns of sensor of capacitance touch screen

A technology of capacitive touch screen and touch screen sensor, which is applied in the direction of instruments, electrical digital data processing, and input/output process of data processing, etc. It can solve the problems of unfavorable popularization, large demand for human resources, and large investment in equipment, so as to save time, Effect of reducing printing process and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

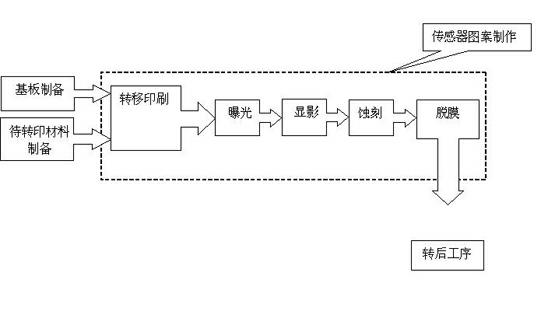

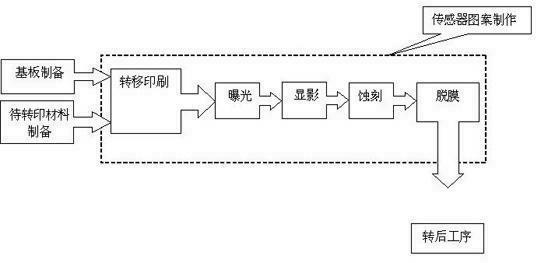

[0015] The technical scheme of the present invention is described in detail below in conjunction with accompanying drawing:

[0016] Such as figure 1 As shown, a method for preparing a pattern of a capacitive touch screen panel includes the following steps: 1) transferring the transparent conductive layer and the photoresist layer to the panel by means of transfer printing, 2) making get the sensor panel.

[0017] The transparent conductive layer and the photoresist layer of the present invention adopt roll-shaped composite materials prepared in advance.

[0018] 1. Substrate preparation: Prepare the base material of the capacitive touch screen panel to the desired state, including strengthening, surface cleaning, and ICON printing (if necessary);

[0019] 2. Preparation of materials to be transferred: prepare transparent conductive layer and photoresist layer to be transferred;

[0020] 3. Transfer printing: transfer the prepared transparent conductive layer and photoresis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com