Three-dimensional printer for horizontally bidirectional printing

A bidirectional printing and printer technology, applied in the field of horizontal bidirectional printing stereoscopic printers, can solve the problems of long printing stroke and low printing efficiency, and achieve the effects of speeding up printing speed, shortening printing stroke and improving stereoscopic printing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

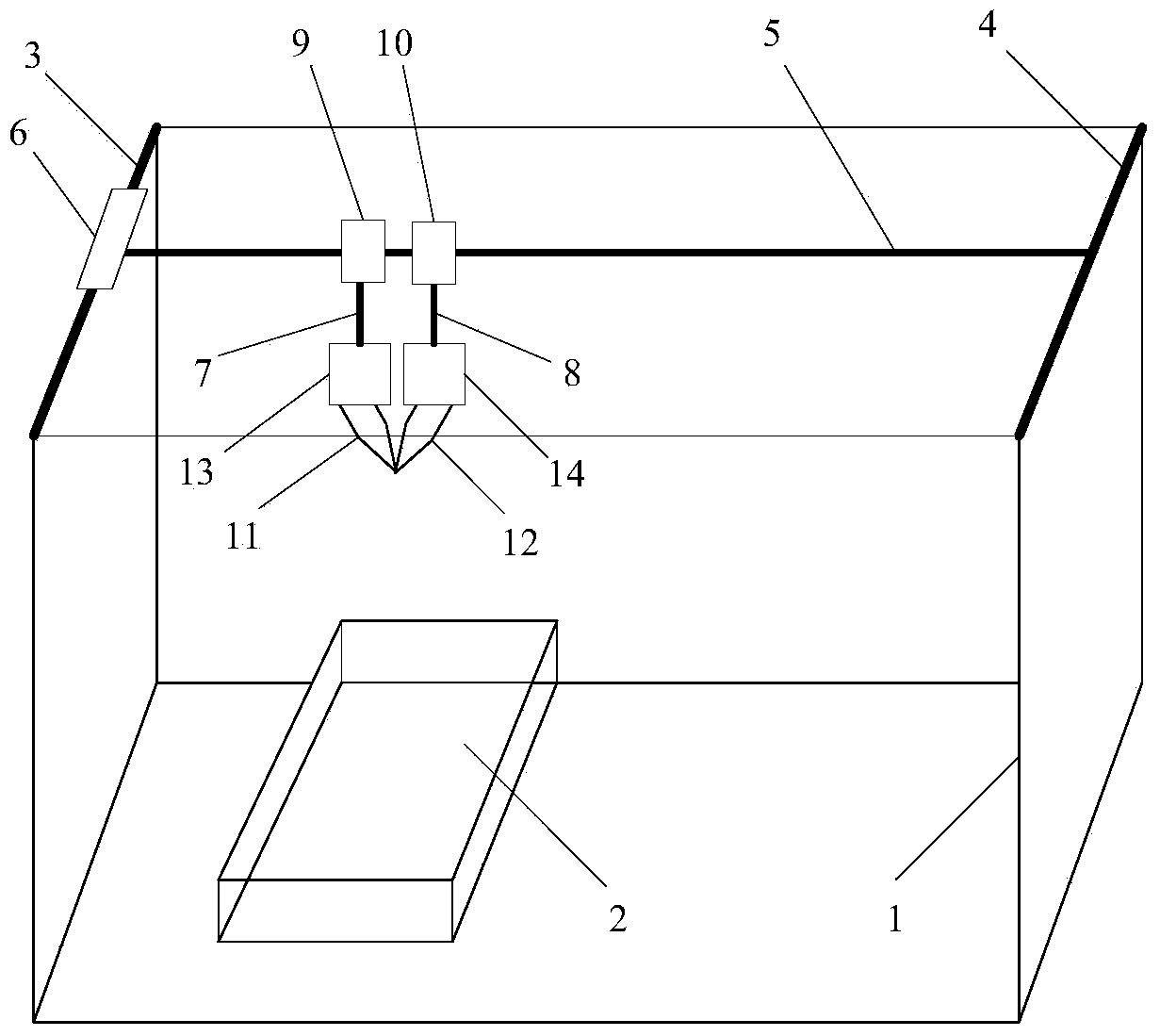

[0015] like figure 1 as shown, figure 1 It is a schematic structural diagram of a horizontal bidirectional printing 3D printer proposed by an embodiment of the present invention.

[0016] refer to figure 1 , the embodiment of the present invention proposes a horizontal two-way printing three-dimensional printer, including: a frame 1, a workbench 2, a first pole 3, a second pole 4, a sliding pole 5, a first driving mechanism 6, a first suspension Rod 7, second boom 8, second drive mechanism 9, third drive mechanism 10, first spray head 11, second spray head 12, fourth drive mechanism 13 and fifth drive mechanism 14, printing material box, heating mechanisms and control units;

[0017] The workbench 2 is located at the bottom of the frame 1, the first pole 3 and the second pole 4 are arranged on the top of the frame 1 in parallel and above the workbench 2, and the plane where the first pole 3 and the second pole 4 are located is on the same plane as the workbench. 2 The surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com