Raised Pad manufacturing method

A production method and operation technology, applied in the field of press bearings, can solve the problems of increasing production costs, using a large amount of ink, and low production efficiency, and achieving the effect of shortening production time, reducing the use of ink, and improving product yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

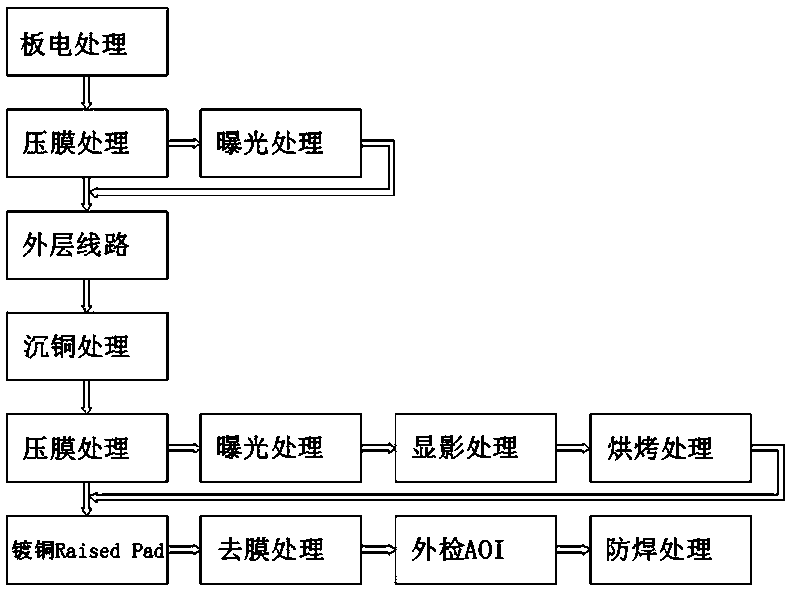

[0033] The method for making the Raised Pad of the present invention will be further described in detail below in conjunction with specific embodiments and accompanying drawings.

[0034] refer to figure 1 According to a non-limiting embodiment of the present invention, a method for manufacturing a Raised Pad includes manufacturing an outer layer circuit, and the manufacturing of the outer layer circuit includes the following steps.

[0035] S1: Board electroplating treatment. After the PCB board is drilled for the inner layer, it enters the board electroplating process, and the entire board is electroplated by electroplating, so that the entire board surface and the walls of the drilled holes are coated with a layer of metal copper, increasing the board surface and The thickness of the copper layer on the hole wall is used to connect the inner layers of the circuit and realize multi-layer interconnection. The plate electrical treatment is produced by copper plating through a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com