Digital inkjet printing ink based on gynura bicolor extract

A technology of digital inkjet and printing ink, which is applied in the field of development of natural plant dyes, can solve the problems of harmful chemical components of printing ink, unfavorable skin, complicated process, etc., achieve good water vapor permeability, reduce environmental pollution problems and improve health Problems, Effects of Conferring Comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) Wash and dry the Avalokitesvara at first, and crush it to 70 meshes;

[0033] (2) Add the pulverized Avalokitesvara powder obtained in step (1) into a three-necked flask, and inject a mixed solvent of ethanol and water into the three-necked flask, and then place the three-necked flask in a water bath at 50°C Preheat and soak for 40min,

[0034] Wherein, in the mixed solvent of ethanol and water, the volume ratio of ethanol and water is 7:3,

[0035] The mass ratio of Avalokitesvara powder added to the three-necked flask to the mixed solvent of ethanol and water is 1:15;

[0036] (3) Put the three-neck flask preheated in step (2) into a microwave oven for enhanced microwave extraction, the microwave power is set to 600W, and the microwave extraction time is set to 120s to obtain the extract;

[0037] (4) Centrifuge the extract obtained in step (3) (4000r / min, 10min), and take the supernatant as the dye solution;

[0038] (5) Concentrating the dye solution obtained...

Embodiment 2

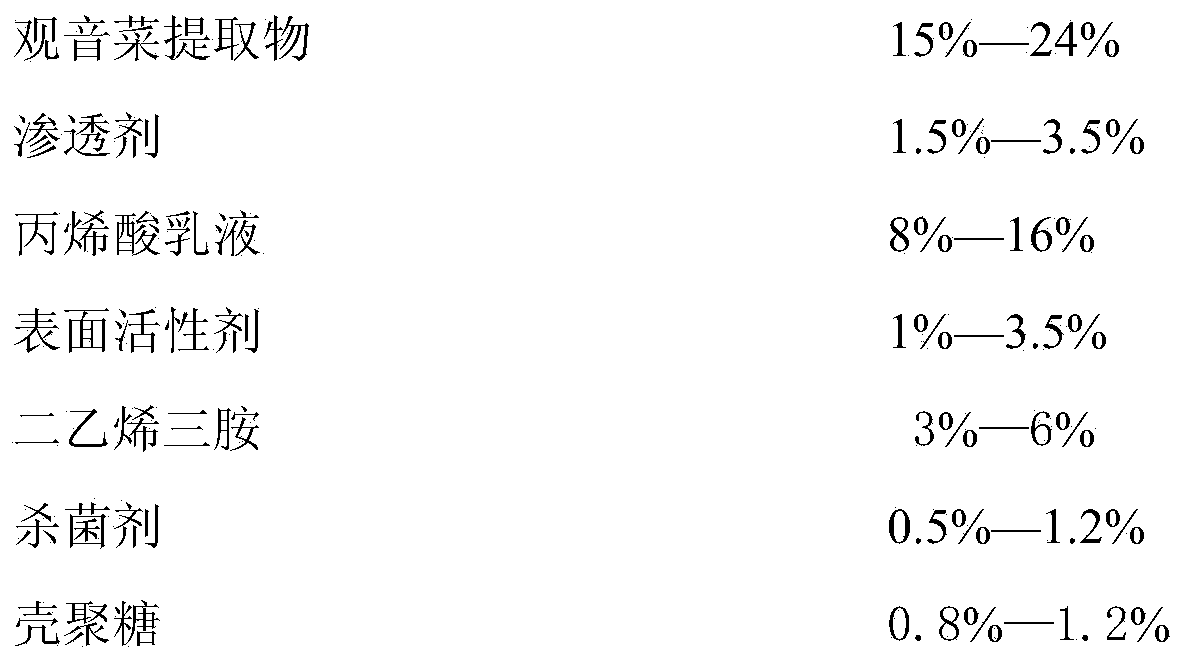

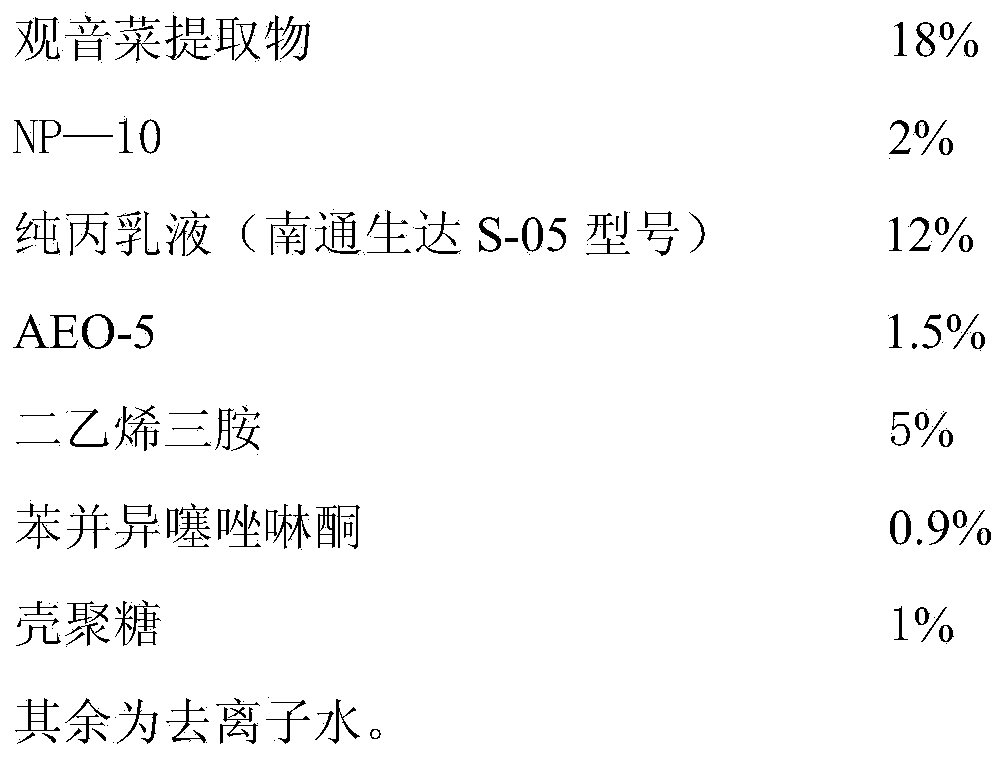

[0044] The Avalokitesvara extract prepared by the method in Example 1 is used as a vegetable dye to prepare digital printing ink, and the weight percentage and process of each component are as follows:

[0045]

[0046]

[0047] The rest is deionized water.

[0048] According to the weight percentage of each component in the above formula, each component is mixed, and the following preparation procedure is the same as that of Example 1.

Embodiment 3

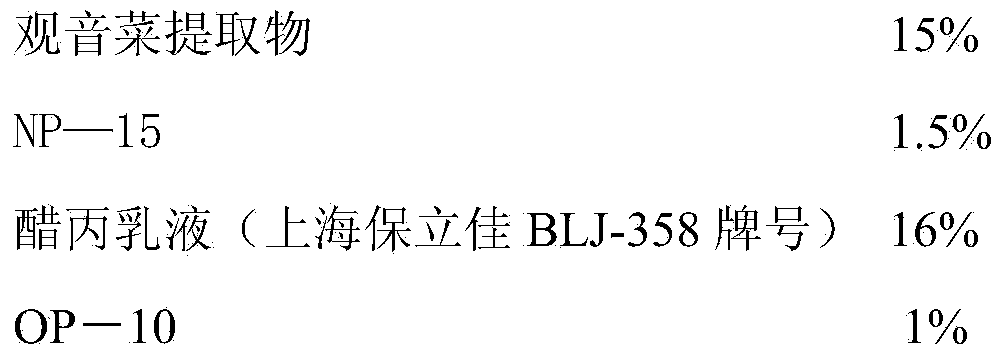

[0050] The Avalokitesvara extract prepared by the method in Example 1 is used as a vegetable dye to prepare digital printing ink, and the weight percentage and process of each component are as follows:

[0051]

[0052] The rest is deionized water.

[0053] According to the weight percentage of each component in the above formula, each component is mixed, and the following preparation procedure is the same as that of Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com