Acid dye and gravure ink as well as preparation method and application of gravure ink

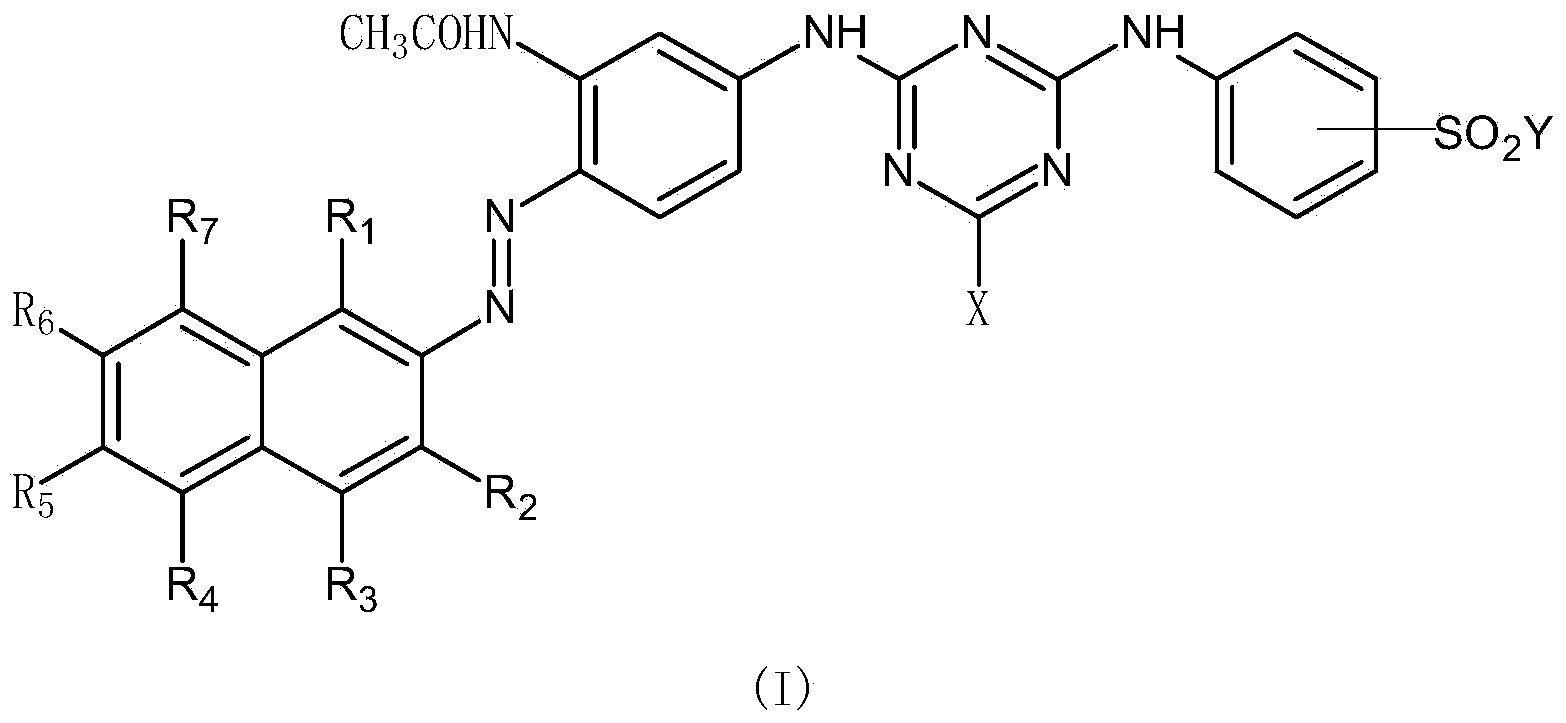

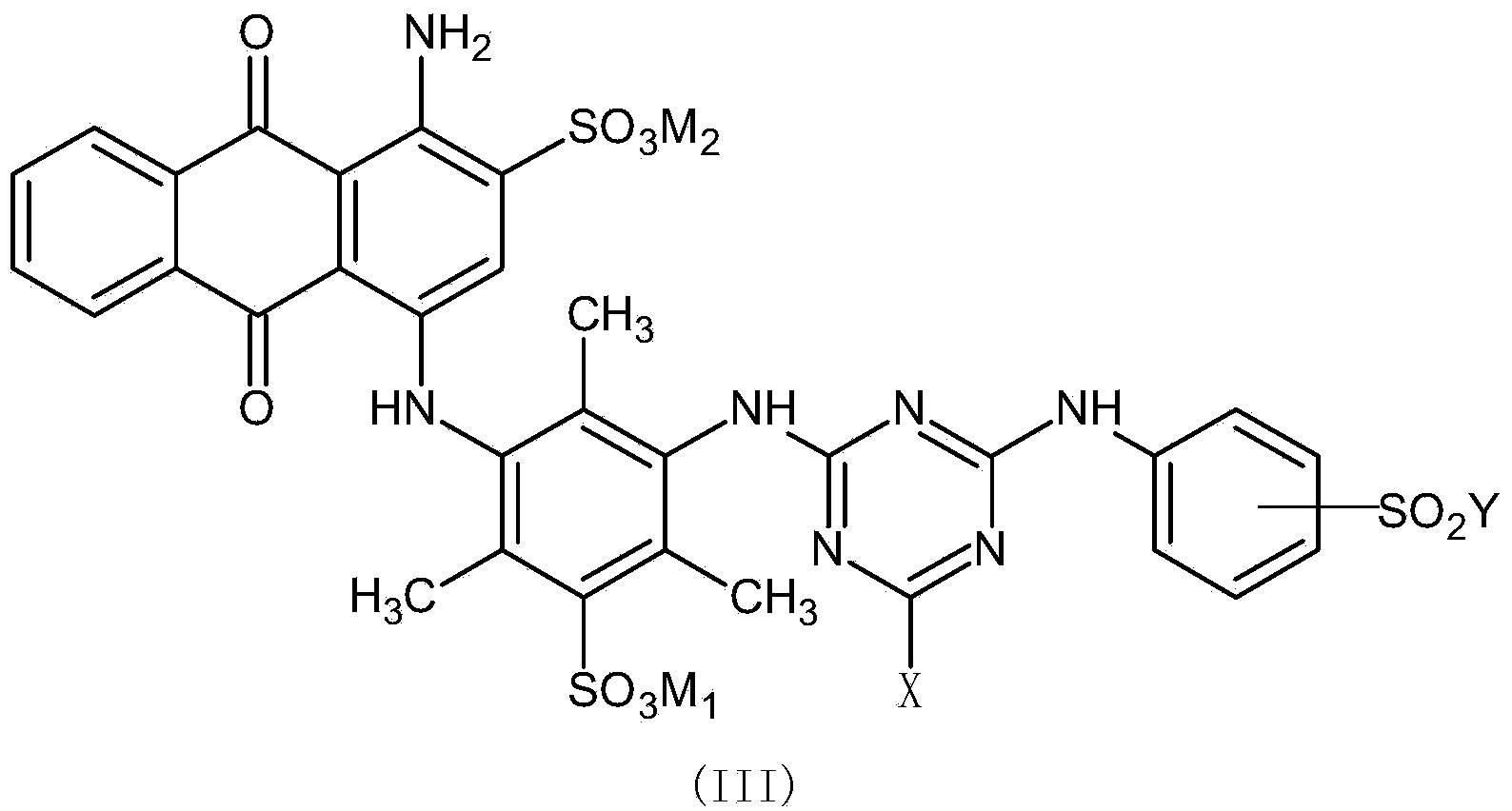

A technology of acid dyes and gravure printing inks, applied in the printing and dyeing industry, can solve the problems of excessive waste water discharge, low dye fixation rate, high dye fixation rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0106] Preparation of acid dye gravure printing ink and its production process of gravure printing 1

[0107] Production materials: Nylon fabric deoiled semi-finished products

[0108] Dyeing chemicals: acid yellow dye shown in formula (I-1), cosolvent, surfactant, pH value stabilizer, viscosity regulator, acid agent, soda ash (2g / L soda ash).

[0109] Production equipment: gravure printing machine, steam box, flat car wash.

[0110] 1. Acid Dye Gravure Ink Preparation

[0111] 1.1 Acid dye gravure ink preparation prescription

[0112]

[0113]

[0114] 1.2 Preparation process of acid dye gravure ink

[0115] Weigh most of the water, add the pH stabilizer, co-solvent, and surfactant into the water under stirring, and stir evenly (for example, the stirring speed is 60 rpm, stirring for 20 minutes) to dissolve them in the water;

[0116] Weigh the acid yellow dye of formula (I-1) and add it to the above solution in batches, stir evenly (for example, the stirring speed ...

Embodiment 2-8

[0129] The acid yellow dye of formula (I-1) in Example 1 is replaced by acid yellow dye of formula (I-2), acid yellow dye of formula (I-3), acid yellow dye of formula (I-4), acid yellow dye of formula (I -1) Mixed acid yellow dye with formula (I-2), mixed acid yellow dye with formula (I-2) and formula (I-3), mix with formula (I-2) and formula (I-4) Acid yellow dye, the mixed acid yellow dye of formula (I-1) and formula (I-2), formula (I-3), all the other are the same as embodiment 1.

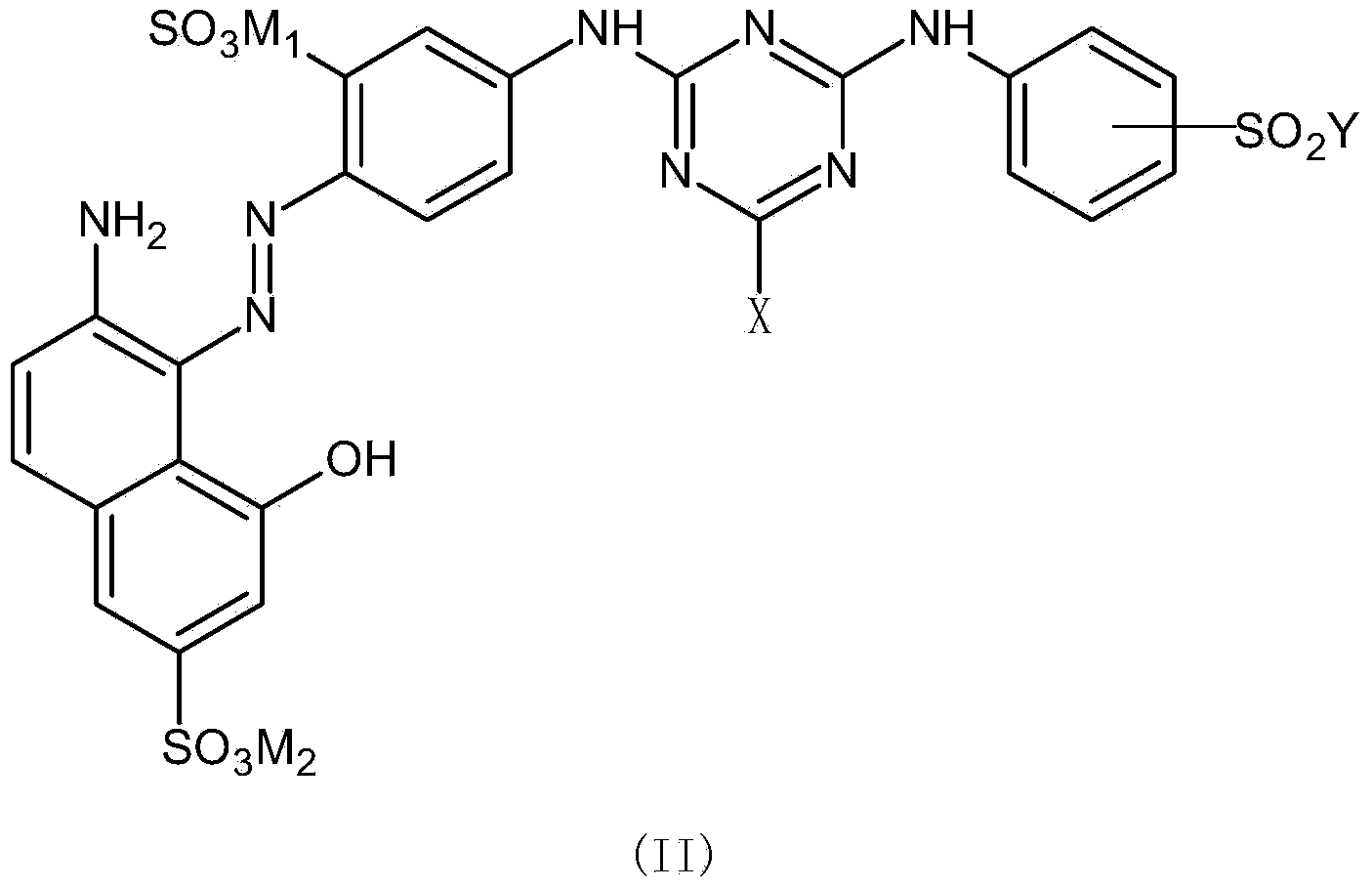

Embodiment 9

[0131] Preparation of acid dye gravure printing ink and its production process of gravure printing 2

[0132] Production materials: Nylon fabric deoiled semi-finished products

[0133] Dyeing chemicals: formula (II-1) acid red dye, cosolvent, surfactant, pH value stabilizer, viscosity regulator, soda lye (2g / L soda ash).

[0134] Production equipment: gravure printing machine, steam box, flat car wash.

[0135] 1. Acid Dye Gravure Ink Preparation

[0136] 1.1 Acid dye gravure ink preparation prescription

[0137]

[0138] 1.2 Preparation process of acid dye gravure ink

[0139] Weigh most of the water, add the pH stabilizer, co-solvent, and surfactant into the water under stirring, and stir evenly (for example, the stirring speed is 80 rpm, stirring for 10 minutes) to dissolve them in the water;

[0140] Weigh the acid red dye of formula (II-1) and add it to the above solution in batches, stir evenly (for example, the stirring speed is 1200 rpm, stirring for 30 minutes)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com