Textile printing method with little amount of water of cotton fabric by utilizing reactive dye

A technology of reactive dyes and printing methods, applied in the field of textile printing, can solve problems such as ecological environment damage, sewage treatment, complex process, etc., and achieve the effects of reducing sewage discharge, reducing content, and improving color fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Embodiment 1: light color I (dye consumption X≤0.5%) printing

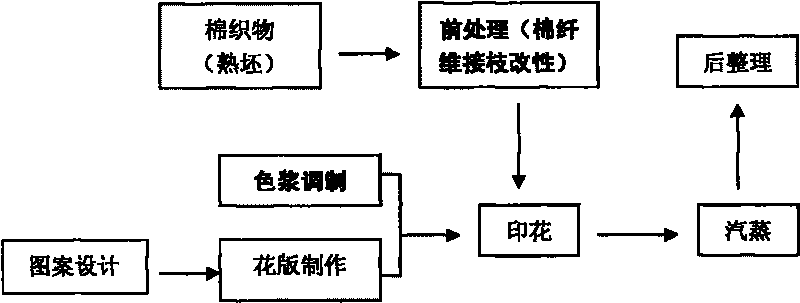

[0040] (1) Printing process, such as figure 1 Shown:

[0041] (2) Formula and process description:

[0042] 1) Pretreatment (cotton fiber graft modification) formula and process:

[0043] Cotton grafting agent HS: 30g / L, double soaking and double rolling (at room temperature, 70-80% liquid), and drying at 105-120°C (3-5min).

[0044] Grafting agent HS for cotton was provided by Zhejiang Huasheng Chemical Co., Ltd.

[0045] 2) Color paste formula and instructions:

[0046] Reactive dye 0.05%, urea 1%, 3-4% synthetic thickener slurry 70%, ammonia water 1%, add water to 100%;

[0047] Due to the low amount of dye used, there is less floating color after printing and steaming, and generally no washing and desizing are required. Therefore, the paste in the color paste is all made of synthetic thickener paste (low solid content, good hand feeling), and the synthetic thickener (polyacrylic acid) is provided ...

Embodiment 2

[0051] Embodiment 2: light color II (dye consumption X≤0.5%) printing

[0052] (1) Printing process, such as figure 1 Shown:

[0053] (2) Formula and process description:

[0054] 1) Pretreatment (cotton fiber graft modification) formula and process:

[0055] Cotton grafting agent HS: 40g / L, double soaking and double rolling (at room temperature, with 70-80% liquid), and drying at 105-120°C (3-5min).

[0056] Grafting agent HS for cotton was provided by Zhejiang Huasheng Chemical Co., Ltd.

[0057] 2) Color paste formula and instructions:

[0058] Reactive dye 0.2%, urea 1.5%, 3-4% synthetic thickener slurry 65%, reinforcing agent 2%, softener 2%; ammonia 2%, add water to 100%;

[0059] Due to the low amount of dye used, there is less floating color after printing and steaming, and generally no washing and desizing are required. Therefore, the paste in the color paste is all made of synthetic thickener paste (low solid content, good hand feeling), and the synthetic thick...

Embodiment 3

[0064] Embodiment 3: light color III (dye consumption X≤0.5%) printing

[0065] (1) Printing process, such as figure 1 Shown:

[0066] (2) Formula and process description:

[0067] 1) Pretreatment (cotton fiber graft modification) formula and process:

[0068] Cotton grafting agent HS: 50g / L, double soaking and rolling (at room temperature, 70-80% liquid), and dry at 105-120°C (3-5min).

[0069] Grafting agent HS for cotton was provided by Zhejiang Huasheng Chemical Co., Ltd.

[0070] 2) Color paste formula and instructions:

[0071] Reactive dye 0.5%, urea 2%, 3-4% synthetic thickener slurry 60%, reinforcing agent 5%, softener 5%; triethanolamine 2%, add water to 100%;

[0072] The same amount of dye is low, and the floating color is less after printing and steaming, and generally no washing and desizing are required. The paste in the color paste is all made of synthetic thickener paste (low solid content, good hand feeling), and the synthetic thickener (polyacrylic aci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com