Preparation method of MWT solar cell

A solar cell and texturing technology, which is applied in the direction of circuits, electrical components, and final product manufacturing, can solve the problems of not achieving optimal cell efficiency results, unsatisfactory cleaning effects, etc. Improves the effect of passivation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

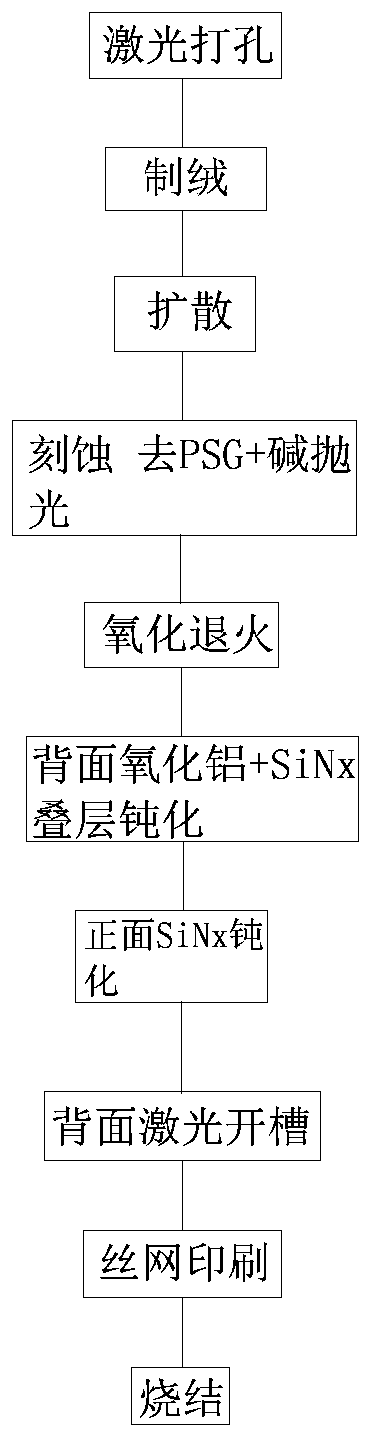

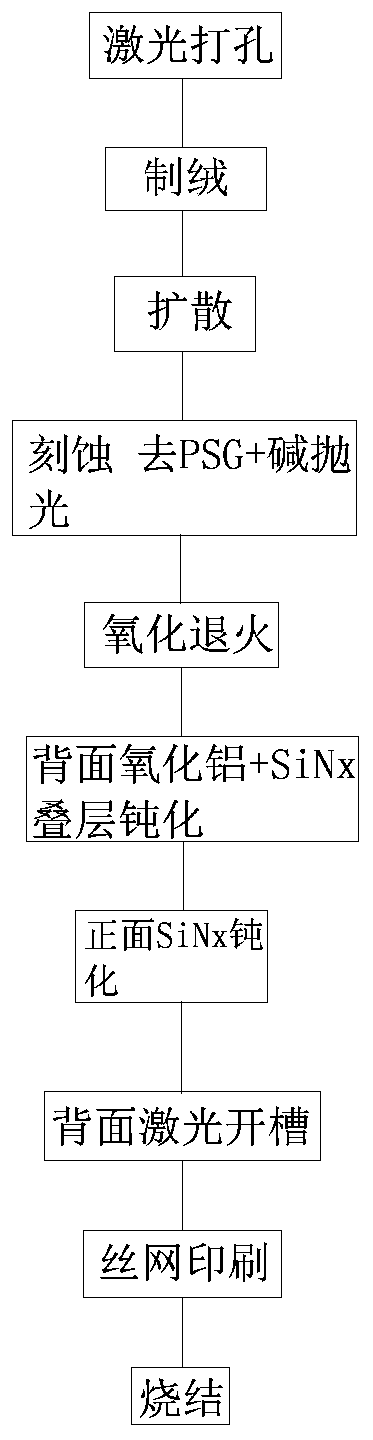

[0030] According to this embodiment figure 1 The flow process in prepares MWT solar cell, concrete steps are:

[0031] 1. Silicon wafer: Solar-grade P-type monocrystalline silicon wafer is used as the substrate.

[0032] 2. Laser drilling: According to the 6×6 hole lattice pattern, use a laser to drill holes on the silicon wafer to form circular holes with a diameter of 0.15mm.

[0033] 3. Texturing: the perforated silicon wafer is made of alkali texturing to form a uniform pyramid textured surface with a reflectivity of 11.2%.

[0034] 4. Diffusion: Place the textured silicon wafers back to back for single-sided phosphorus diffusion. The diffusion temperature is 850°C, the diffusion time is 90min, and the square resistance is 90Ω / □.

[0035] 5. Etching: 1) After the silicon wafer is diffused, use a chain machine under the protection of a water film to remove the back of the silicon wafer and the phosphorosilicate glass ( PSG), phosphosilicate glass is a by-product of phosp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com