Sawtooth micropore anti-counterfeiting method and printed matter

A technology of printed matter and micro-holes is applied in the anti-counterfeiting field of information query, which can solve the problems of increasing manufacturing cost, reducing production efficiency, and consuming diffusing agent, and achieving the effects of reducing manufacturing difficulty, improving production efficiency and reducing manufacturing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

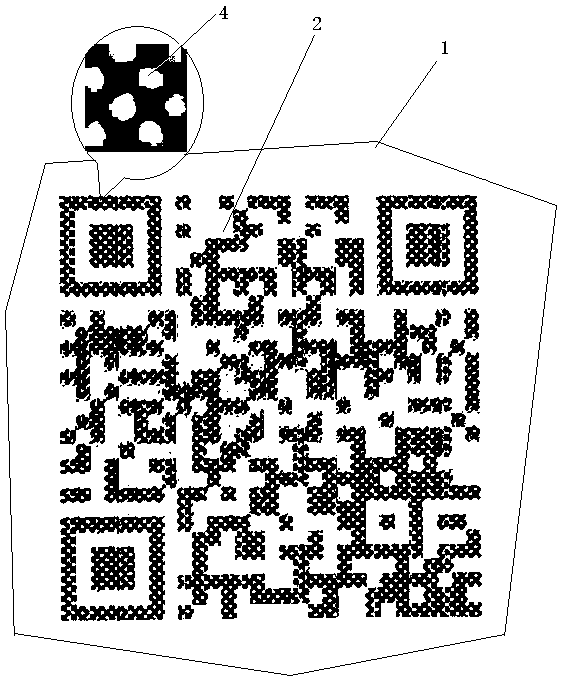

[0058] produce a figure 1 Print shown (1).

[0059] At least one unique code (2) is spray-printed for each printed matter (1).

[0060] The first step is to generate a batch of unique coding (2) electronic image files in the computer in advance, and preset some 0.15mm wide square artificial microholes (7) on the coding (2) electronic images, see Figure 8 .

[0061] The second step is to use a liquid ink with a surface tension of Y, such as UV inkjet ink, to print the code (2) of the artificial micropore (7) preset with a square onto the printed matter (1) whose surface energy is C On the surface, where C>Y; for example, pre-print a partially wet coating with a surface energy C greater than 48 dynes / cm, and then use a liquid ink with a surface tension Y less than 24 dynes / cm to code (2) or / and graphics (3) are printed on the partial wetting coating; all in all, the selected liquid ink can infiltrate the selected printing surface, that is, the greater the difference betwe...

Embodiment 2

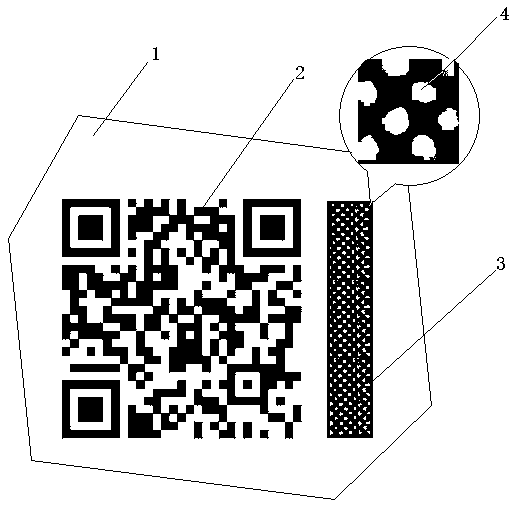

[0067] produce a figure 2 Print shown (1).

[0068] Each printed matter (1) is spray-printed with at least one unique code (2) and graphic (3).

[0069]The first step is to generate a batch of unique codes (2) and text (3) in the computer in advance, and preset some artificial micropores (7) with a diameter of 0.05mm on the electronic image of the text (3) , see Image 6 .

[0070] The second step is to select a liquid ink with a surface tension of Y, spray-print the code (2) onto the printed matter (1), and spray-print the graphic (3) preset with artificial micropores (7) onto a surface energy of C on the printing surface, where Y>C; for example, pre-print a partial non-wetting coating with a surface energy C greater than 28 dyne / cm, and then use a liquid ink with a surface tension Y less than 48 dyne / cm to print the graphic (3) Spray printing on the partial non-wetting coating; in a word, the selected liquid ink can not infiltrate the selected printing surface, that is,...

Embodiment 3

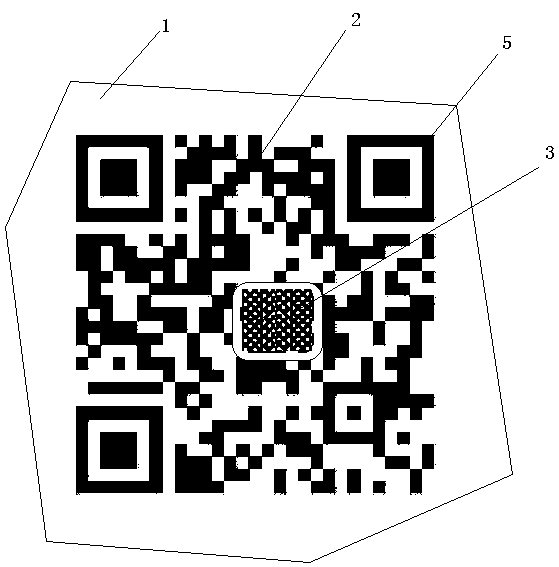

[0078] produce a Figure 5 Print shown (1).

[0079] At least one unique code (2) is spray-printed for each printed matter (1).

[0080] The first step is to generate a batch of unique codes (2) in the computer in advance, and preset some artificial micropores ( 7).

[0081] The second step is to use liquid ink with a surface tension of Y, and print the code (2) onto the printing surface with a surface energy of C, where C>Y; for example, pre-print a surface energy C greater than 38 dyne / centimeters of partially wetted coating, and then spray-print the code (2) onto the partially wetted coating with a liquid ink having a surface tension Y of less than 28 dynes / cm; in general, the greater the difference between C and Y, the better, but C and Y It should not be equal or close; only in this way can the artificial micropores (7) surrounded by the liquid ink shrink naturally and randomly deform under the action of the infiltration force, so that the artificial micropores (7) pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com