Secondary molding plug connector and manufacturing method thereof

A plug connector and connector technology, which is applied in the direction of connection, contact manufacturing, and components of connecting devices, etc., can solve the problems of easy oxidation, unusable use, exposed copper and other problems in environmental testing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

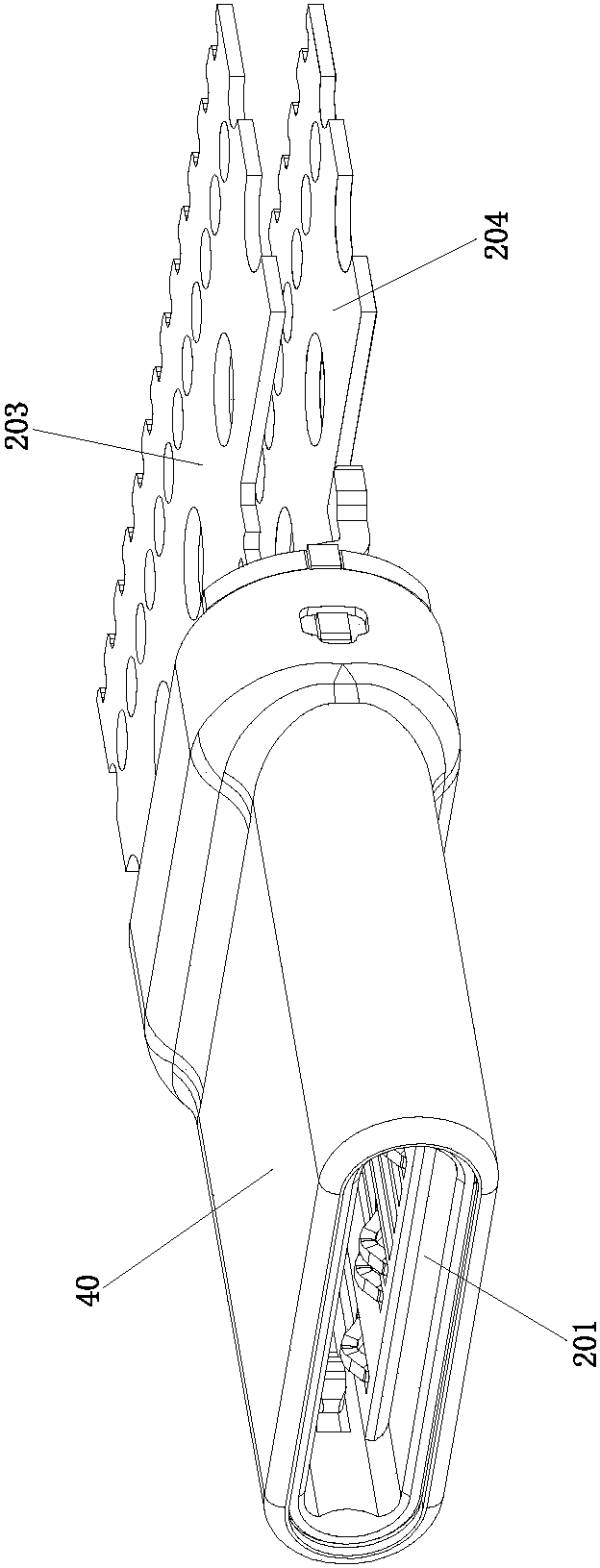

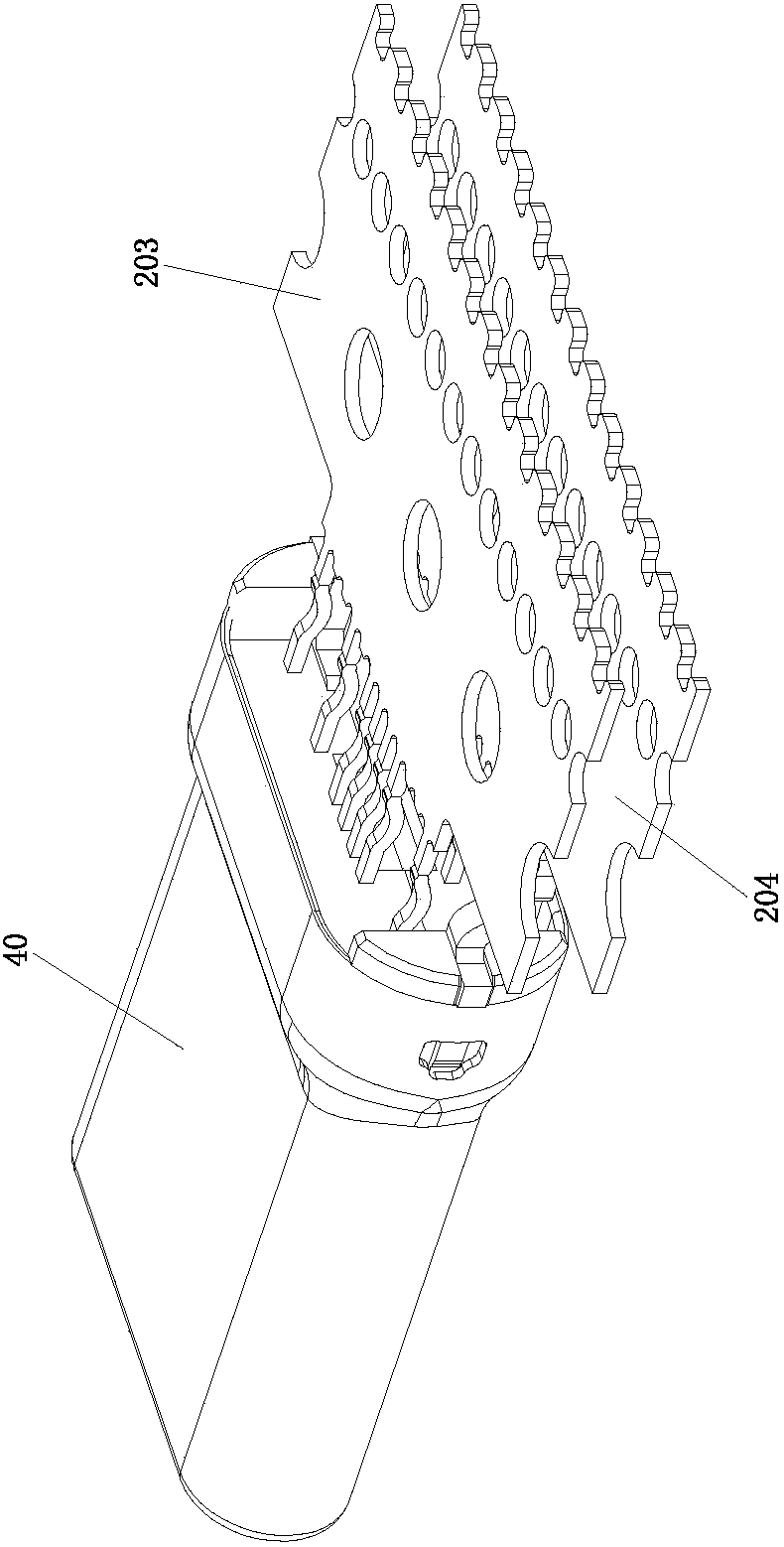

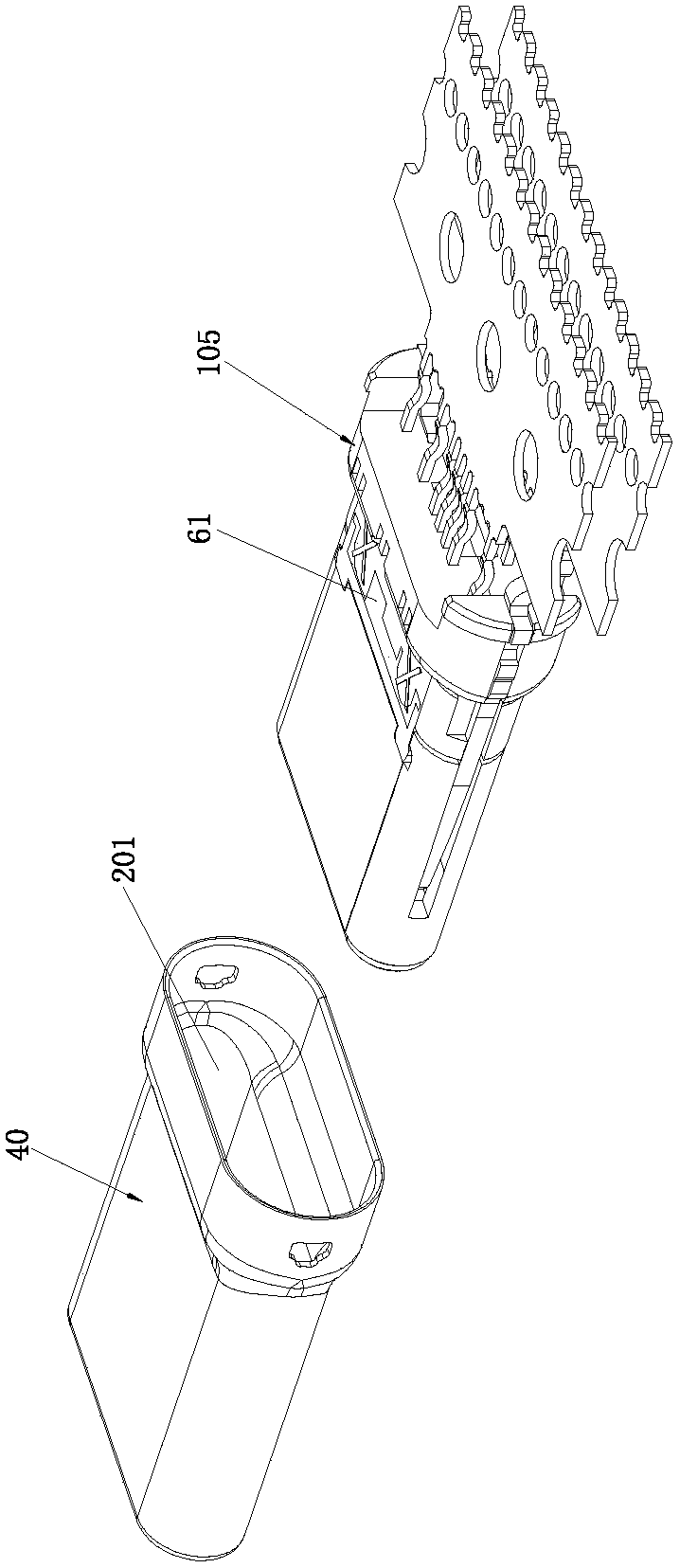

[0067] Please refer to Figure 1 to Figure 10 As shown, it shows the specific structure of the embodiment of the present invention.

[0068] Wherein, the plug connector includes a primary molding upper row terminal module 101, a primary molding lower row terminal module 102, a first insulating body 10 and a shielding shell 40; the primary molding upper row terminal module 101 includes an upper row of terminals 20 and The upper row of second insulating bodies 60, the lower row of terminal modules 102 of the primary molding include the lower row of terminals 30 and the lower row of second insulating bodies 70; the upper row of terminals 20 and the lower row of terminals 30 have contact parts from front to back , connecting portion, welding portion; the connecting portion of the upper row of terminals 20 is insert-molded in the upper row of second insulating body 60 to form a molding upper row terminal module 101; the connecting portion of the lower row of terminals 30 is insert-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com