PH regulator, water-based steel structure anticorrosive coating containing the pH regulator and capable of preventing weld joint flash rust and preparation method

A technology of anti-corrosion coatings and conditioners, applied in anti-corrosion coatings, polyester coatings, coatings, etc., can solve the problems of difficult to completely eliminate rust spots, pressure, poor storage stability, etc., and achieve the effect of avoiding natural loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

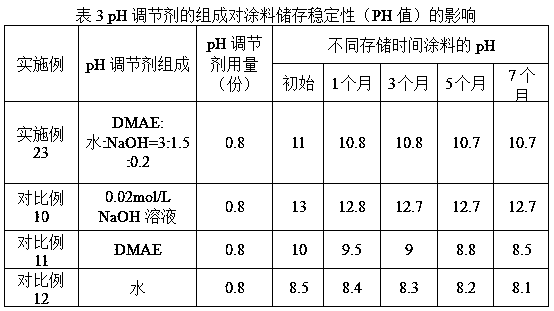

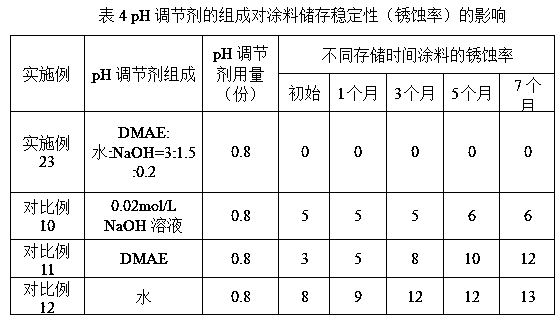

[0053] A pH adjuster is prepared from DMAE, water and sodium hydroxide solution in a mass ratio of 3:1.5:0.2, and the concentration of the sodium hydroxide solution is 0.02mol / L.

Embodiment 2

[0055] A pH regulator is prepared from DMAE, water and sodium hydroxide solution in a ratio of 2:2:0.3, and the concentration of the sodium hydroxide solution is 0.02 mol / L.

Embodiment 3

[0057] A pH adjusting agent is prepared from DMAE, water and sodium hydroxide solution in a ratio of 1:1:0.2, and the concentration of the sodium hydroxide solution is 0.02mol / L.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com