Automatic powdering box for anode of secondary battery

A secondary battery, powder box technology, applied in electrode manufacturing and other directions, can solve the problems of not conforming to the development trend of low-carbon economy and green energy, high use and maintenance costs, restricting the development of secondary batteries, etc., to avoid short circuits or microelectronics. Short circuit, simple and compact structure, and the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with specific drawings and embodiments.

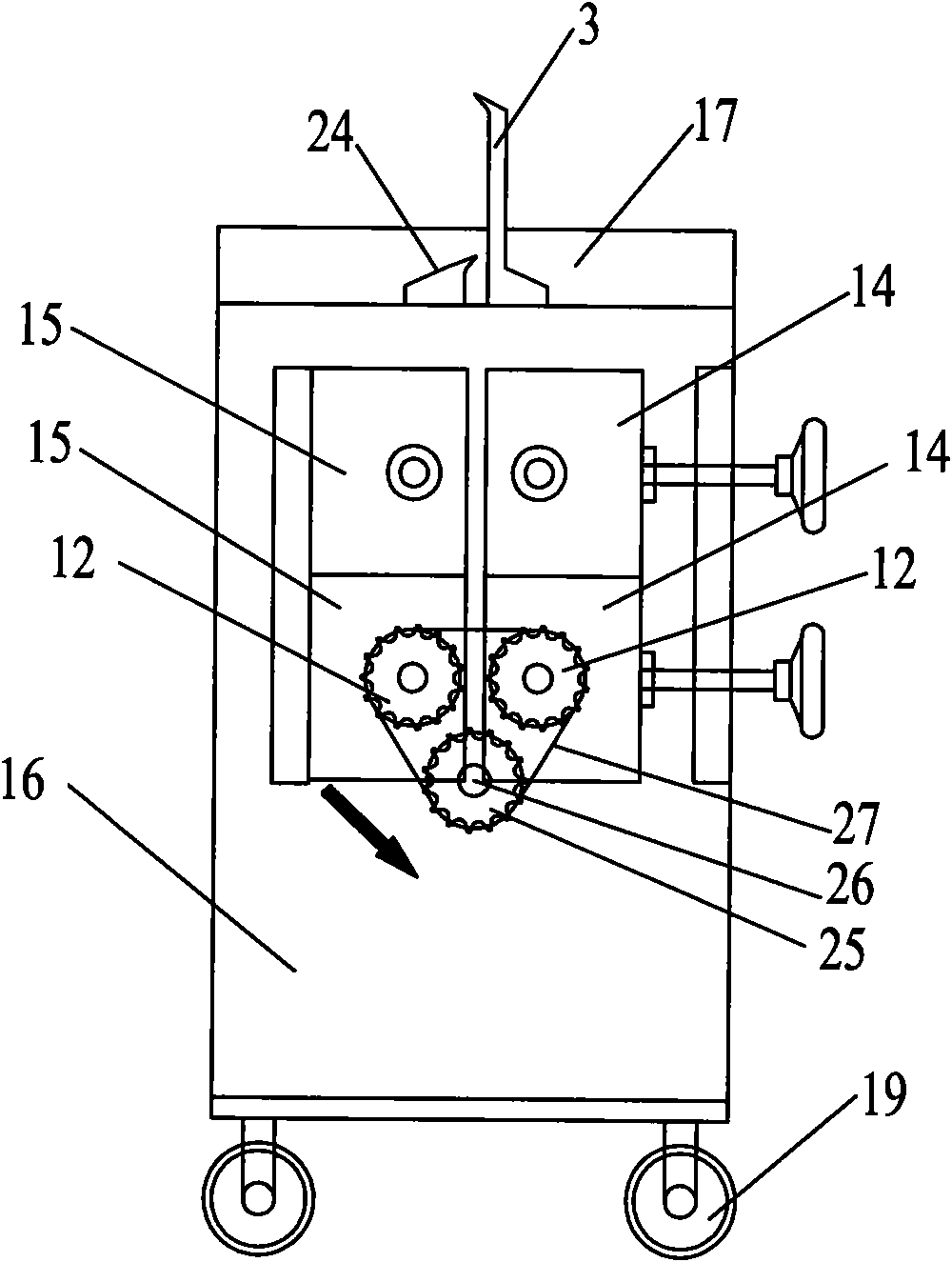

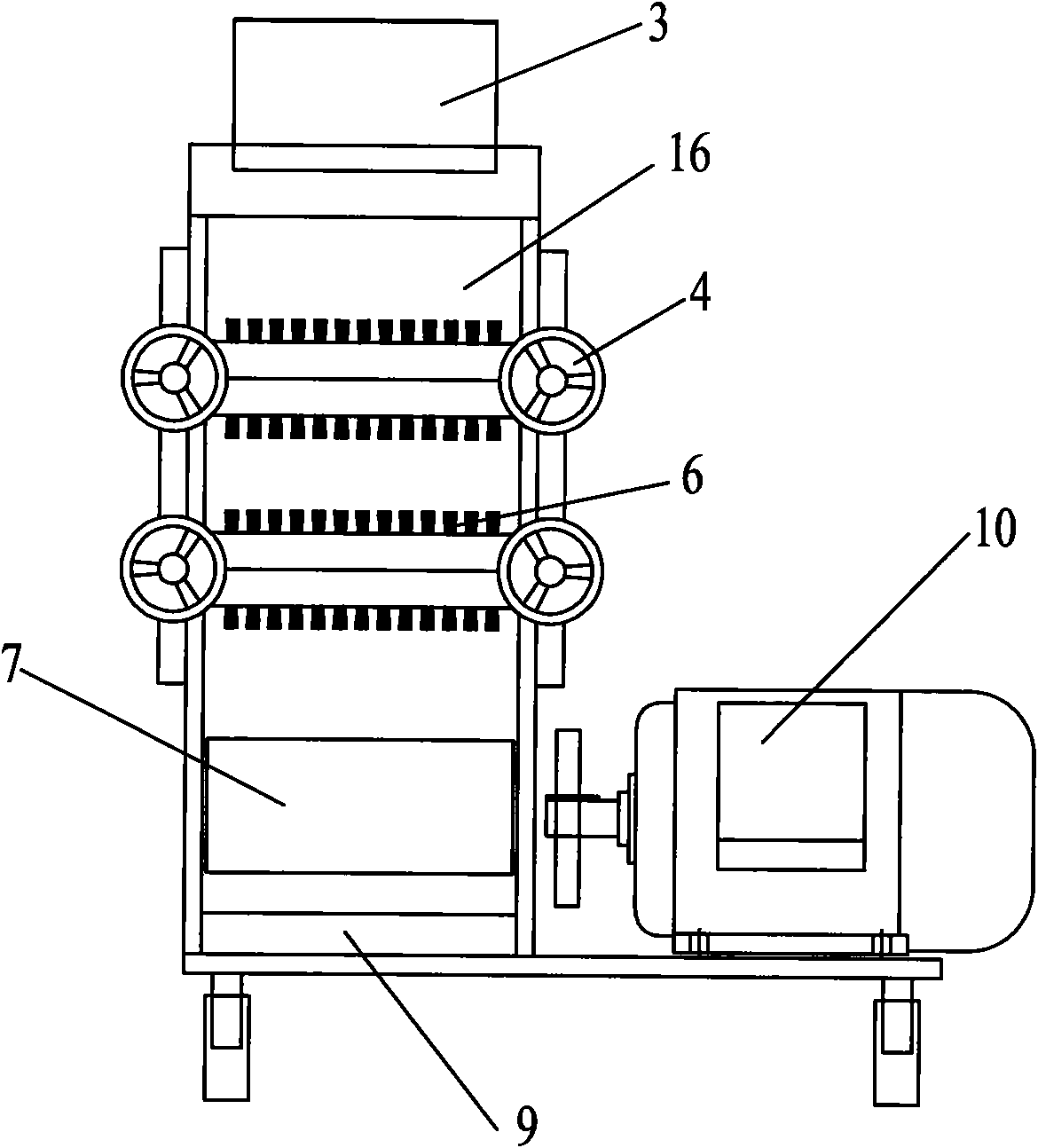

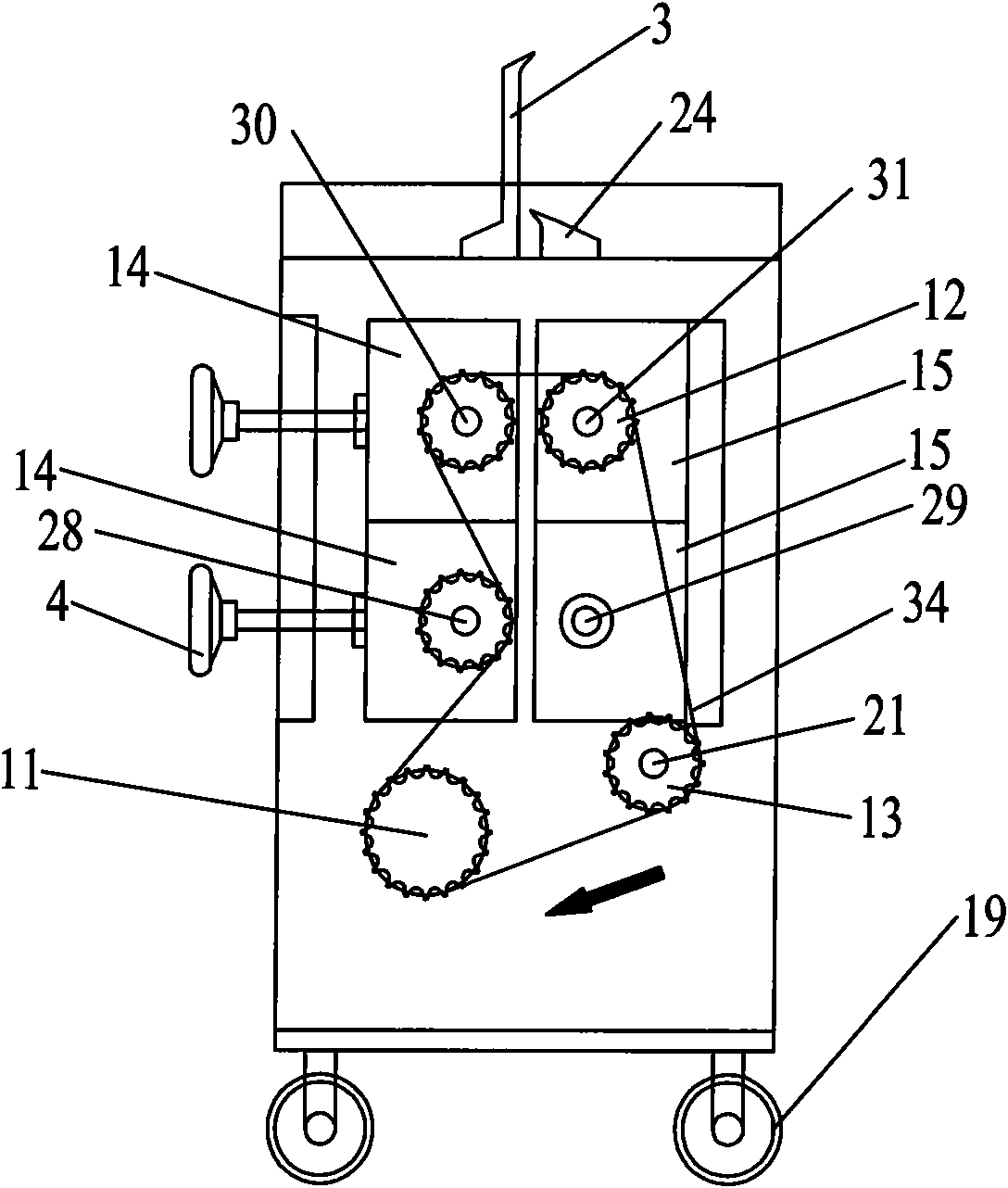

[0014] like Figure 1 to Figure 4 Shown: the present invention comprises foamed nickel 1, rolling mill guide wheel 2, first scraper 3, adjusting hand wheel 4, first fine brush 5, first rough brush 6, powder feed box guide wheel 7, powder cleaning plate 8, Cleaning powder receiving basin 9, reduction motor 10, driving sprocket 11, driven sprocket 12, first tensioning sprocket 13, movable slider 14, fixed slider 15, box body 16, installation block 17, first Silo plate 18, roller 19, guide wheel mounting shaft 20, first tensioning sprocket mounting shaft 21, second silo plate 22, handle 23, second scraper 24, second tensioning sprocket 25, second Tight chain wheel mounting shaft 26, the second chain 27, the first rotating shaft 28, the second rotating shaft 29, the third rotating shaft 29, the fourth rotating shaft 31, the second coarse brush 32, the second fine ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com