Preparation process of lithium battery diaphragm

A lithium battery diaphragm and a preparation process technology, applied in the field of lithium battery diaphragm preparation technology, can solve problems such as short circuit, non-permanent electronic conductivity of the diaphragm, large pore size, etc., achieve uniform pore size distribution, long-lasting ionic conductivity, and improve flexibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

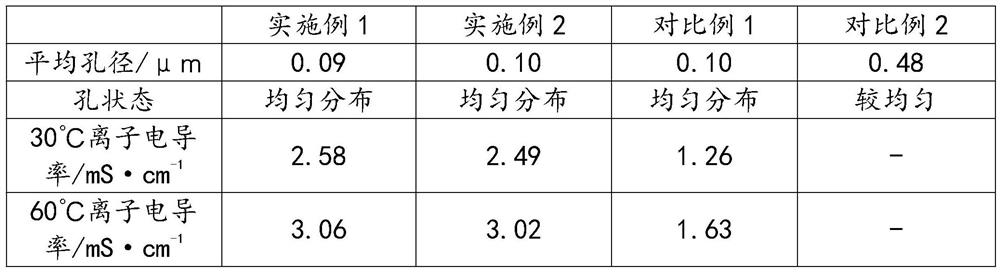

Examples

preparation example Construction

[0023] A preparation process of a lithium battery diaphragm includes the following steps:

[0024] The first step is to dissolve the modified polyimide in N-methylpyrrolidone, fully stir to dissolve, and use a vacuum pump to vacuum and de-air bubbles to obtain a casting solution with a modified polyimide mass fraction of 20-25% ,Store the casting solution at 2-3℃;

[0025] In the second step, electrospinning the casting solution, spinning at a spinning voltage of -4~22kV, a solution advance rate of 10mL / h, room temperature and humidity below 50%, to obtain a prefabricated fiber membrane;

[0026] The third step is to place the nanofiber membrane in a high-temperature oven, and raise the temperature to 300°C at a rate of 3.5°C / min for 8-10 minutes. After the reaction, stop heating and take it out after the temperature drops to room temperature to obtain a fiber membrane;

[0027] The fourth step, put the fiber membrane on the coating machine, use a 4μm gravure roll to coat the boehmite...

Embodiment 1

[0037] A preparation process of a lithium battery diaphragm includes the following steps:

[0038] The first step is to dissolve the modified polyimide in N-methylpyrrolidone, fully stir to dissolve, and use a vacuum pump to vacuum and degas bubbles to obtain a casting solution with a modified polyimide mass fraction of 20%. The casting liquid should be stored at 2-3℃;

[0039] In the second step, electrospinning the casting solution, spinning at a spinning voltage of -4~22kV, a solution advance rate of 10mL / h, room temperature and humidity below 50%, to obtain a prefabricated fiber membrane;

[0040] The third step is to place the nanofiber membrane in a high-temperature oven, and raise the temperature to 300°C at a rate of 3.5°C / min for 8 minutes. After the reaction, stop heating and take it out after the temperature drops to room temperature to obtain a fiber membrane;

[0041] The fourth step is to put the fiber membrane on the coating machine, use a 4μm gravure roll to coat the b...

Embodiment 2

[0043] A preparation process of a lithium battery diaphragm includes the following steps:

[0044] The first step is to dissolve the modified polyimide in N-methylpyrrolidone, fully stir to dissolve, and use a vacuum pump to vacuum and degas bubbles to obtain a casting solution with a modified polyimide mass fraction of 25%. The casting liquid should be stored at 2-3℃;

[0045] In the second step, electrospinning the casting solution, spinning at a spinning voltage of -4~22kV, a solution advance rate of 10mL / h, room temperature and humidity below 50%, to obtain a prefabricated fiber membrane;

[0046] The third step is to place the nanofiber membrane in a high-temperature oven, and raise the temperature to 300°C at a rate of 3.5°C / min for 10 minutes. After the reaction, stop heating and take it out after the temperature drops to room temperature to obtain a fiber membrane;

[0047] The fourth step is to place the fiber membrane on the coating machine, use a 4μm gravure roll to coat th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com