Production of flexible circuit board

A flexible circuit board and manufacturing method technology, applied in the direction of printed circuit, removal of conductive materials by chemical/electrolytic methods, printed circuit components, etc. The effect of solving the insufficient top width and avoiding the phenomenon of micro-short circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the flexible circuit board manufacturing method of the grain soft film bonding manufacturing process provided by the present invention more clear, how to form a copper metal wire structure with an appropriate top width on the flexible circuit board is described in detail in the embodiment of the present invention.

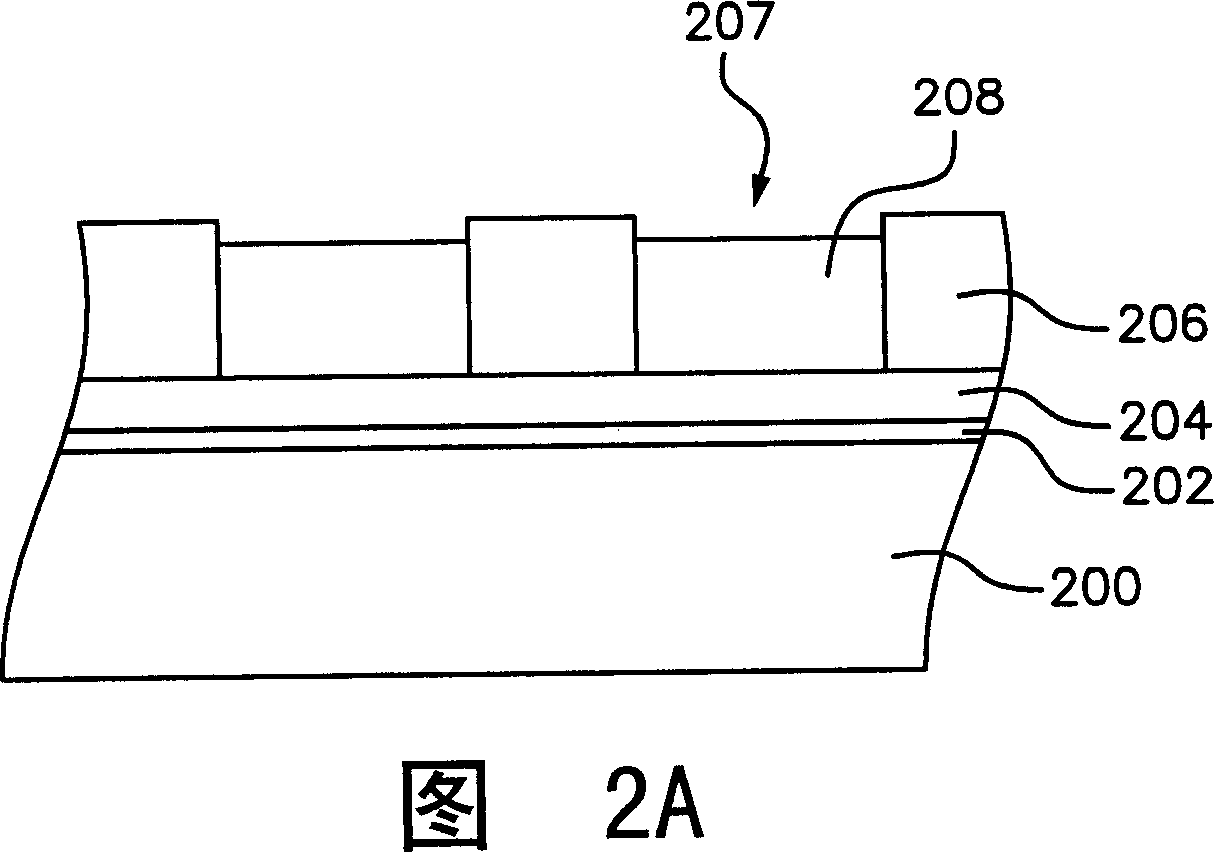

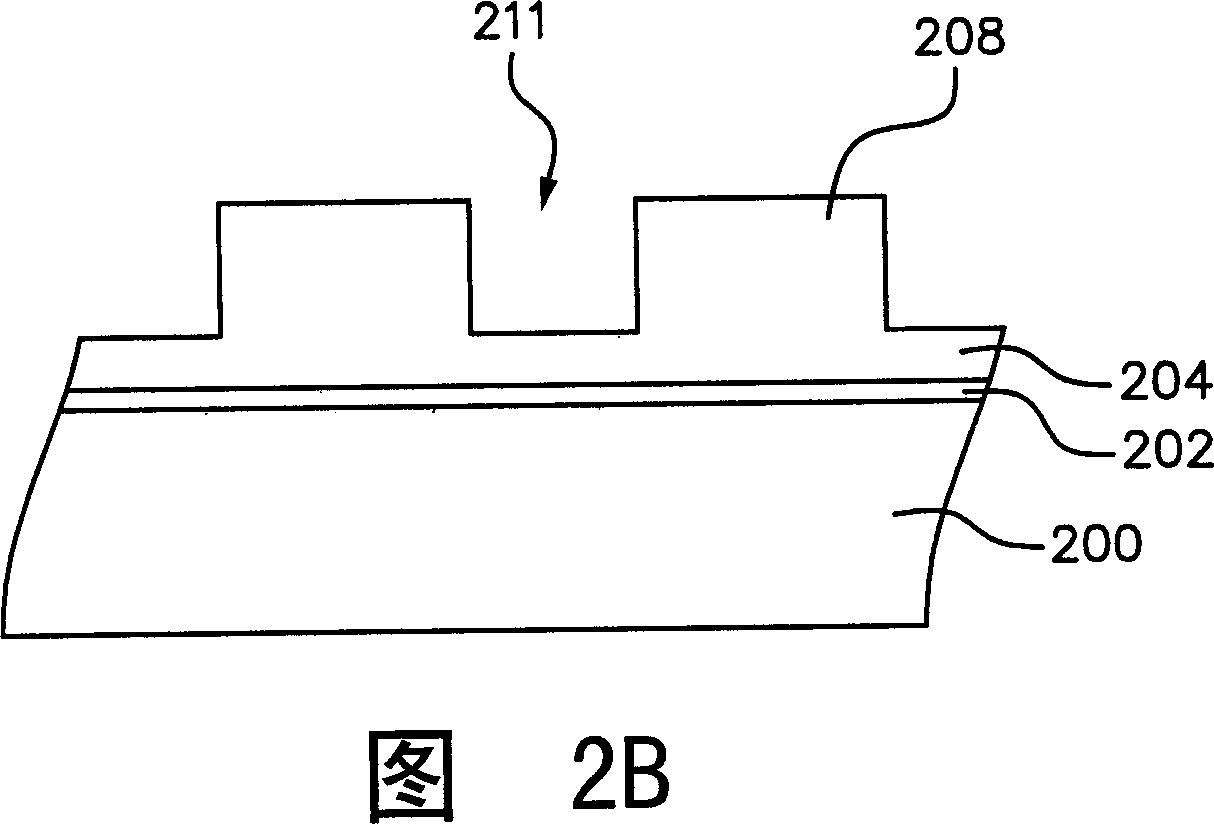

[0024] 3A to 3E are schematic cross-sectional views illustrating the manufacturing process of the flexible circuit board according to the embodiment of the present invention. Referring to FIG. 3A , an alloy layer 302 and a copper metal layer 304 are sequentially provided on a PI substrate 300 . Wherein, the material of the alloy layer 302 may be nickel-chromium alloy, and there is a copper seed layer (not shown in the figure) between the copper metal layer 304 and the alloy layer 302 . A patterned photoresist layer 306 is formed on the copper metal layer 304 , and the patterned photoresist layer 306 has openings 307 . Using the patterned ph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com