Isolating membrane, preparation method thereof, lithium ion secondary battery and device

A technology of separator and porous base film, applied in secondary batteries, batteries, battery pack components, etc., can solve the problems of reducing the weight and energy density of lithium-ion batteries, easy to pierce the separator, and a large proportion of boehmite, etc. Achieve the effects of improving thermal stability and chemical stability, increasing physical area, and excellent heat shrinkage resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

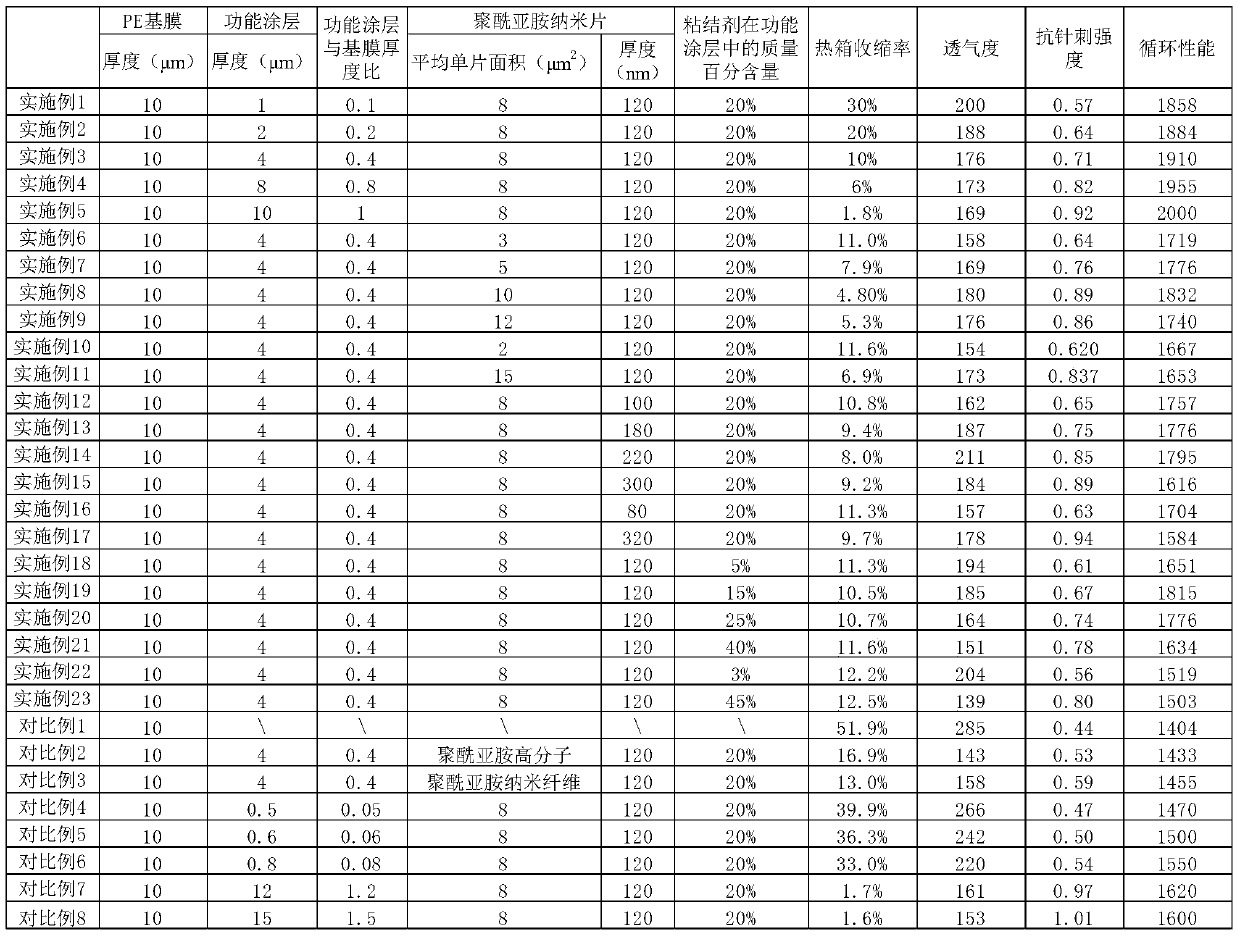

[0025] According to the second aspect of the present application, the embodiment of the present application provides the preparation method of the above-mentioned separator, which includes: (1) mixing polyimide nanosheets, adhesives and deionized water to obtain polyimide nanosheets An aqueous sheet dispersion liquid; wherein, the polyimide nano sheet and the binder have a mass percent content of 6-50%, and the balance is deionized water. (2) coating the aqueous dispersion of polyimide nanosheets on at least one surface of the porous base film to form a functional coating, the thickness ratio of the functional coating to the porous base film is 0.1 to 1.0, Dry to obtain the isolation film.

[0026] In the above-mentioned preparation method provided by the present application, the formulation of the polyimide nanosheet aqueous dispersion is adjusted so that the formed dispersion has very good stability, and the stable slurry is applied to the bare surface by coating technology. ...

Embodiment 1-23

[0034] (1) Preparation of separator

[0035] Mix the polyimide nanosheets, binder and deionized water to obtain an aqueous dispersion of polyimide nanosheets; wherein, the polyimide nanosheets and binder are mixed in the polyimide nanosheet aqueous dispersion The total mass percent content ranges from 6 to 50 percent, wherein the ratio of the polyimide nano sheet to the binder is: 5 to 40:60 to 95 by mass.

[0036] The aqueous dispersion of polyimide nanosheets is coated on both surfaces of the polyolefin base film by coating equipment commonly used in the art to form a functional coating, and the thickness of the functional coating and the porous base film is The ratio is 0.1-1.0, and it is dried at 60-80° C. to obtain a separator.

[0037] (2) Preparation of positive pole piece

[0038] The positive electrode active material lithium cobaltate, the conductive agent conductive carbon, and the binder polyvinylidene fluoride (PVDF) are uniformly mixed at a mass ratio of 96:2:2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com