Heat-conducting lithium ion diaphragm and preparation method thereof

A lithium ion and separator technology, applied in the field of battery separator preparation, can solve the problems of excessive heat that cannot be effectively and quickly dissipated, battery safety performance attenuation, etc., and achieve the effects of high difficulty in dispersion, improved electrochemical performance, and good physical and chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

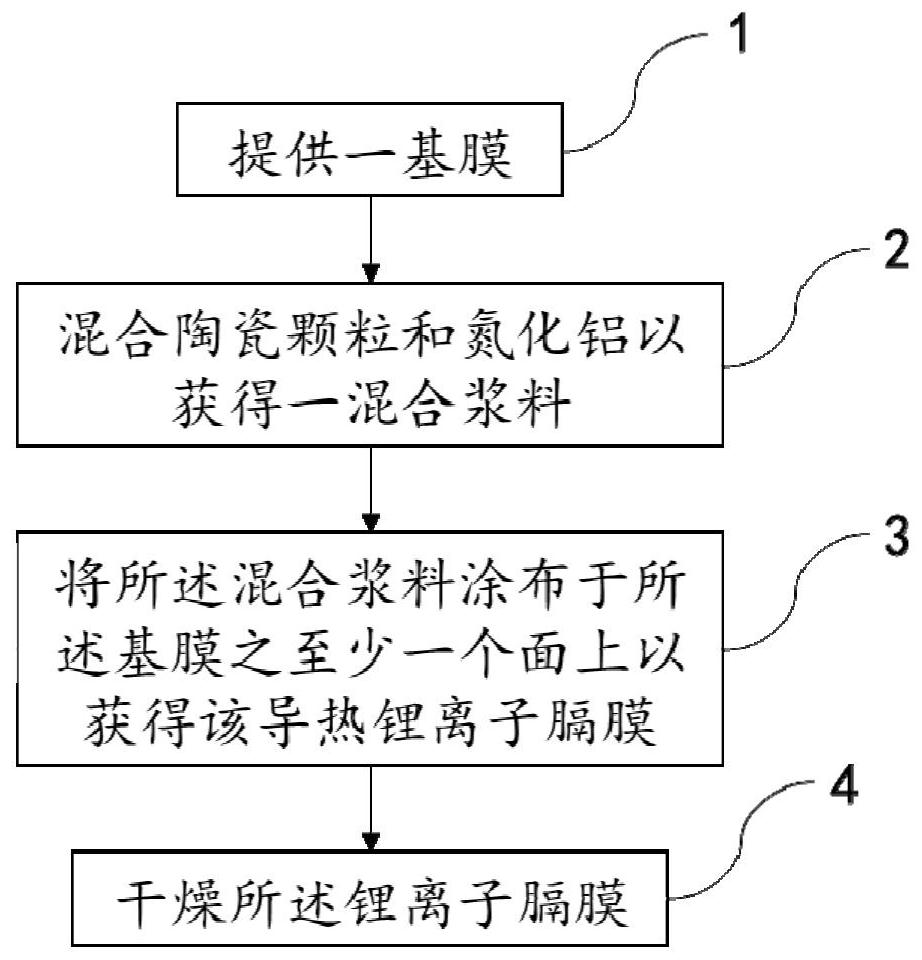

[0038] Another embodiment of the present invention is a method for preparing a thermally conductive lithium-ion separator, which is mainly divided into three steps: provision of wet base film—preparation of coating slurry—slurry coating. For more details, please refer to image 3 , which is a specific flow chart illustrating the preparation method of this embodiment, the method includes steps:

[0039] 1) providing a base film;

[0040] 2) mixing ceramic particles and aluminum nitride to obtain a mixed slurry; and

[0041] 3) Coating the mixed slurry on at least one surface of the base film to obtain the thermally conductive lithium ion diaphragm, wherein the mixed slurry is coated at a coating speed by a wire rod or a gravure roll Cloth, the coating speed is between 50m / min-80m / min.

[0042] In some preferred embodiments, the method further comprises the steps of:

[0043] 4) drying the lithium ion diaphragm, the drying temperature is between 70 ° C and 100 ° C; specifical...

Embodiment 1

[0073] Provide base film: In this example, the provided PE base film is prepared according to the conventional wet process. The base film obtained by this process has high porosity, uniform pore size, high mechanical strength, good safety and can be prepared in thickness Ultra-thin products; in this example, the thickness of the base film is preferably 9 μm and the porosity is 50%. The preparation process of the base film of this thickness is mature, the consistency of the diaphragm is good, the porosity can be adjusted arbitrarily, and it has outstanding mechanical properties and safety performance .

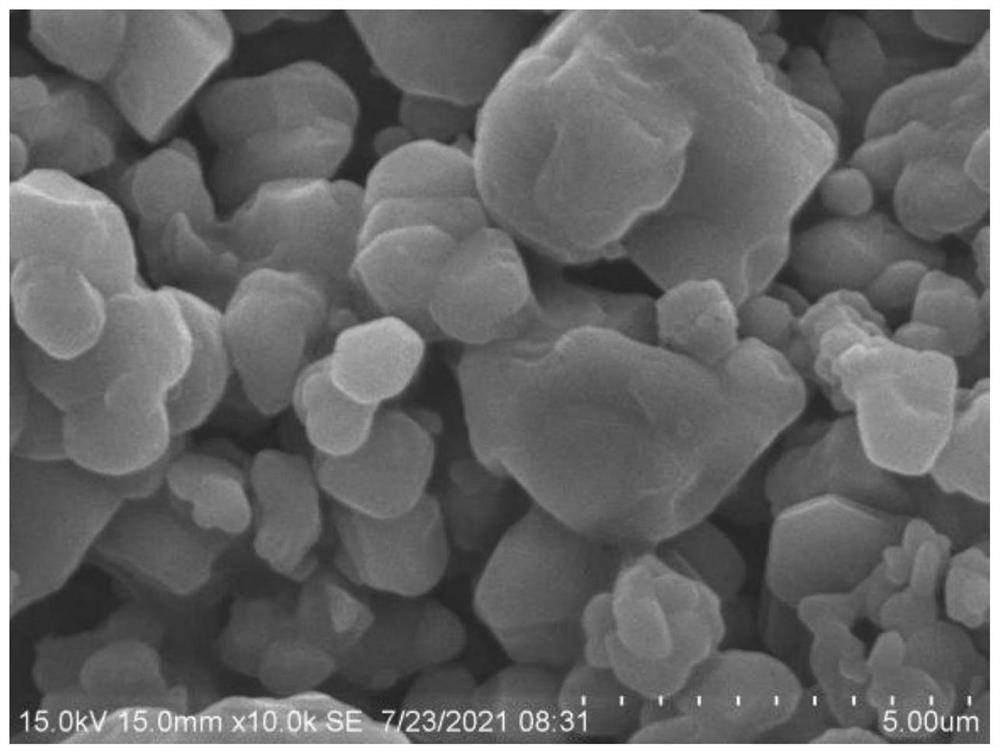

[0074] Preparation of coating slurry: water and carboxymethyl cellulose (Carboxymethyl Cellulose, CMC) are mixed in a ratio of 100:1 to 100:5, and water and CMC are mechanically stirred to obtain a transparent and clear CMC solution. Next, mix ceramic particles and aluminum nitride particles at a weight ratio of 6:1, add them to the CMC solution in batches, and then stir at a c...

Embodiment 2

[0083] The steps of the preparation method are the same as in Example 1, please refer to Table 1, but the following preparation conditions are different:

[0084] The dry weight ratio of organic solvent to inorganic particles is 5.5%.

[0085] The weight ratio of ceramic particles to aluminum nitride is 1:1.5.

[0086] The D50 of aluminum nitride particles is 4μm, and the weight per unit area is 3g / m 2 .

[0087] Ceramic particle D50 is 0.6μm, specific surface area is 10m 2 / g.

[0088] The thermally conductive lithium ion separator prepared in Example 2 has a thermal conductivity of 175W / m K, a thermal shrinkage coefficient of 6% (MD) and 5% (TD) respectively, a moisture content of 679ppm, and an internal resistance of 1.38Ω*cm 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com