Paper base printing circuit board with protective layer and preparation method thereof

A printed circuit board and printed circuit technology, which is applied to printed circuit parts, printed circuit secondary treatment, non-metallic protective layer coating, etc., can solve problems such as key failure, improve reliability, simple production process, avoid The effect of micro-short circuit phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044]A paper-based printed circuit board with a protective layer includes a paper-based printed circuit board with electronic components, and a protective layer. The protective layer is a conformal coating. The components and contents of the conformal coating are: siloxane grafted polyurethane-polyacrylate (PUA) 56%, siloxane modified acrylate 34%, photoinitiator 1173 (2-hydroxyl 2-methylbenzene Proxyl acetone-1) 6.0%, coupling agent dibutyltin dilaurate 0.5%, leveling agent polysiloxane-polyether copolymer 0.5%, defoamer dimethyl polysiloxane 2.25%, wetting agent Cross-linked silicone polyether acrylate 0.25%.

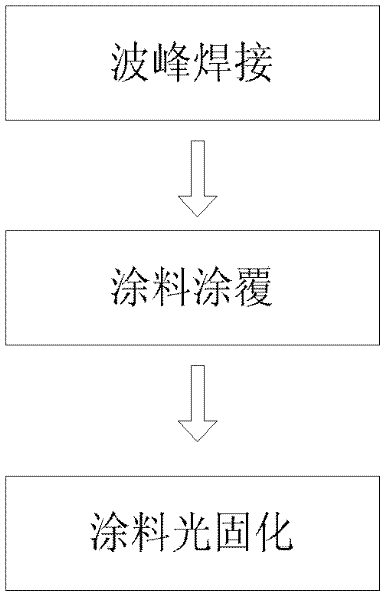

[0045] Such as figure 1 As shown, the paper-based printed circuit board with the protective layer is made through the following steps: (1) electronic components are fixed on the blank board of the paper-based printed circuit board by wave soldering to obtain a paper-based printed circuit board with electronic components (2) coating the conformal coating on the wel...

Embodiment 2

[0050] Compared with Example 1, the difference of this example is that the composition content of the conformal coating is different: 61% of siloxane grafted polyurethane-polyacrylate (PUA), 35% of siloxane-modified acrylate, Photoinitiator 1173 (2-hydroxyl 2-methyl phenylacetone-1) 3.0%, coupling agent dibutyltin dilaurate 0.5%, leveling agent polysiloxane-polyether copolymer 0.1%, defoamer Dimethicone 0.2%, wetting agent cross-linked silicone polyether acrylate 0.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com