Manufacturing method of electrode for battery

一种电池电极、电极的技术,应用在电池电极、电极制造、电解质蓄电池制造等方向,能够解决电池可靠性降低等问题,达到可靠性提高、避免碎屑的产生、避免微短路的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

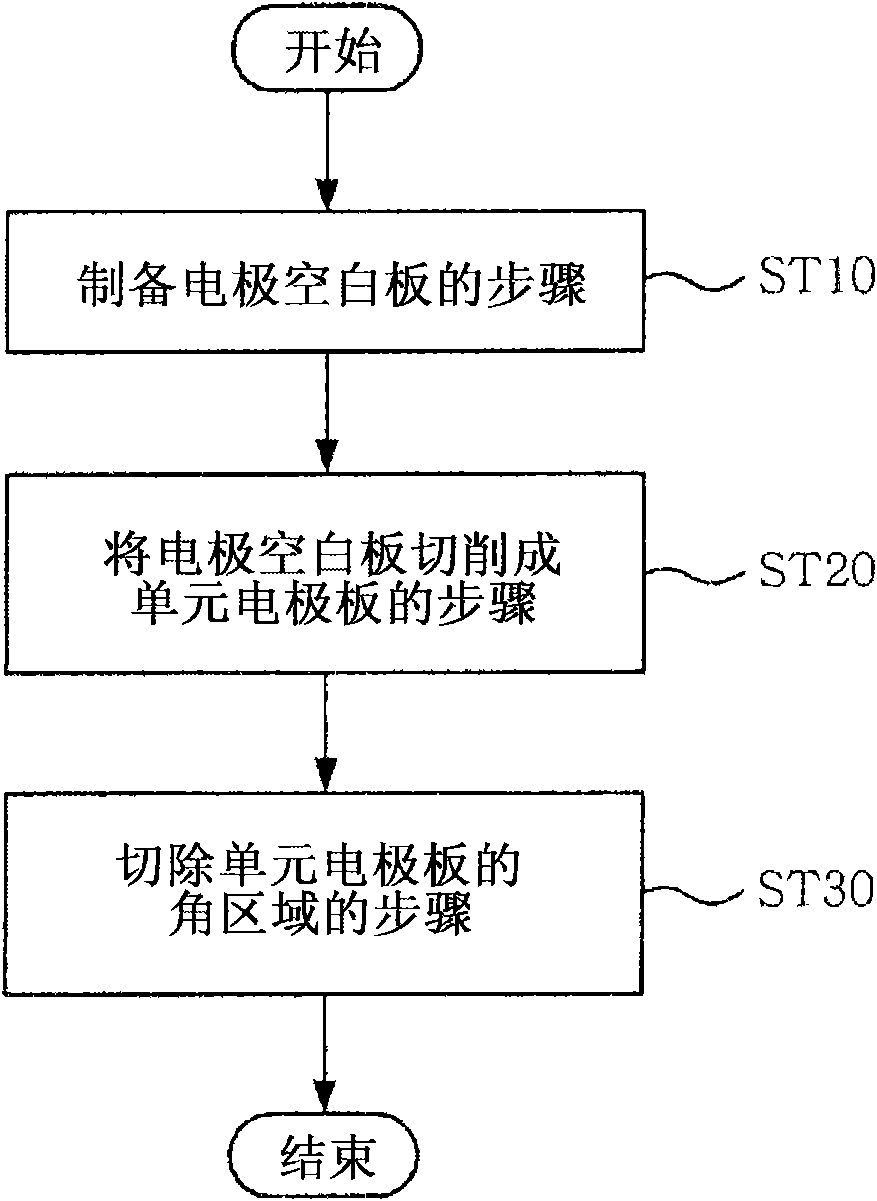

[0044] Hereinafter, a method for fabricating a battery electrode according to an embodiment of the present invention will be described with reference to the accompanying drawings.

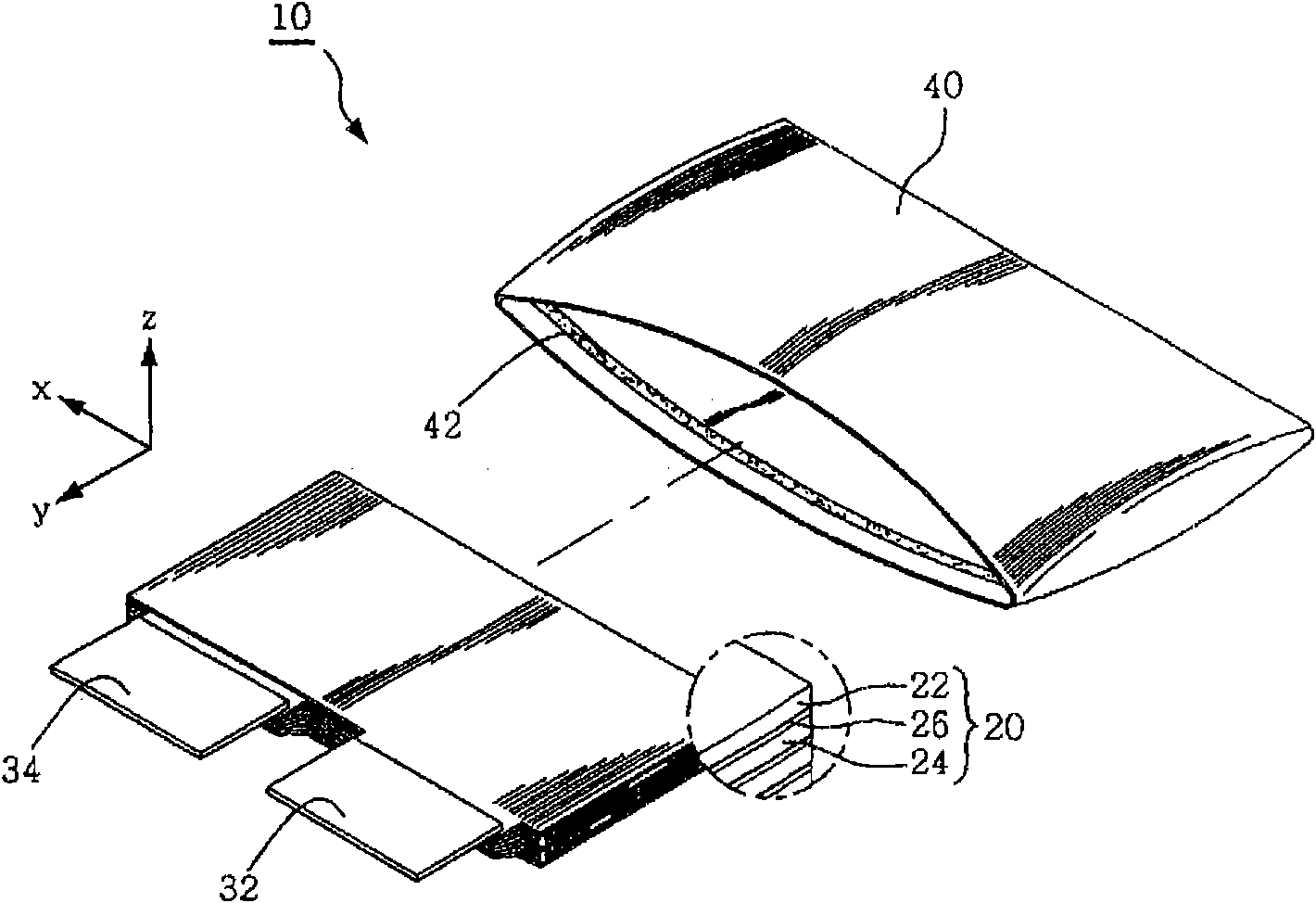

[0045] figure 1 is a perspective view illustrating a lithium secondary battery equipped with electrodes made according to an embodiment of the present invention.

[0046] like figure 1 As shown, the lithium storage battery 10 according to the present invention includes a first electrode 22 (cathode, hereinafter referred to as "positive electrode"), a second electrode 24 (anode, hereinafter referred to as "negative electrode"), and an electrode located between the positive and negative electrodes. The electrode set 20 composed of the separator 26, the first electrode post 32 (hereinafter referred to as "positive electrode post") and the second electrode post 34 (hereinafter referred to as "negative electrode post") connected to the positive electrode 22 and the negative electrode 24 respectively ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com