Production method facilitating orderly collection of fibers

A production method and fiber technology are applied in the production field where fibers are easy to collect neatly, can solve the problems of messy fiber bundles, low labor intensity efficiency, etc., and achieve the effects of convenient operation, simple structure, and improved fiber collection efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

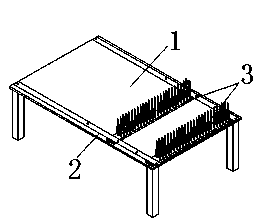

[0023] Embodiment one, such as figure 1 As shown, the production method of the present invention is easy to neatly collect fibers, which includes the following steps: A1: tool preparation step; A2: start collection step; A3: reinforcement step; A4: collection end step.

[0024] Preferably, in the step A1: the grate is placed on the desktop with the grate facing upwards, and the two ends of the grate are pressed with a pressure plate to fix the grate on the desktop.

[0025] Preferably, in the step A2: arrange the loosened fiber bundles in the same direction, and then lay them on the grates evenly and layer by layer.

[0026] Preferably, in step A2, step A21 is also performed: the grate moves between the pressing plate and the tabletop along the fiber pulling direction.

[0027] Preferably, in step A2, step A22 is also performed: the width of the laid fiber bundle is less than or equal to the width of the grate teeth.

[0028] Preferably, in step A3: insert a plurality of gra...

Embodiment 2

[0033] Embodiment two, such as figure 1 As shown, a kind of raw material of the present invention that is easy to collect fibers neatly

[0034] A production method, which includes the following steps: A1: tool preparation step; A2: start collection step; A3: reinforcement step; A4: collection end step.

[0035] Preferably, in the step A1: the grate is placed on the desktop with the grate facing upwards, and the two ends of the grate are pressed with a pressure plate to fix the grate on the desktop.

[0036] Preferably, in the step A2: arrange the loosened fiber bundles in the same direction, and then lay them on the grates evenly and layer by layer.

[0037] Preferably, in step A2, step A21 is also performed: the grate moves between the pressing plate and the tabletop along the fiber pulling direction.

[0038] Preferably, in step A2, step A22 is also performed: the width of the laid fiber bundle is less than or equal to the width of the grate teeth.

[0039] Preferably, i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com