Pineapple picking machine

A technology for picking machines and pineapples, which is applied in the direction of harvesters, agricultural machinery and tools, instruments, etc., can solve the problems of difficult transportation, easy cuts to workers, damage, etc., to improve picking and collection efficiency, reduce picking damage, and increase collection The effect of capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below with reference to the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

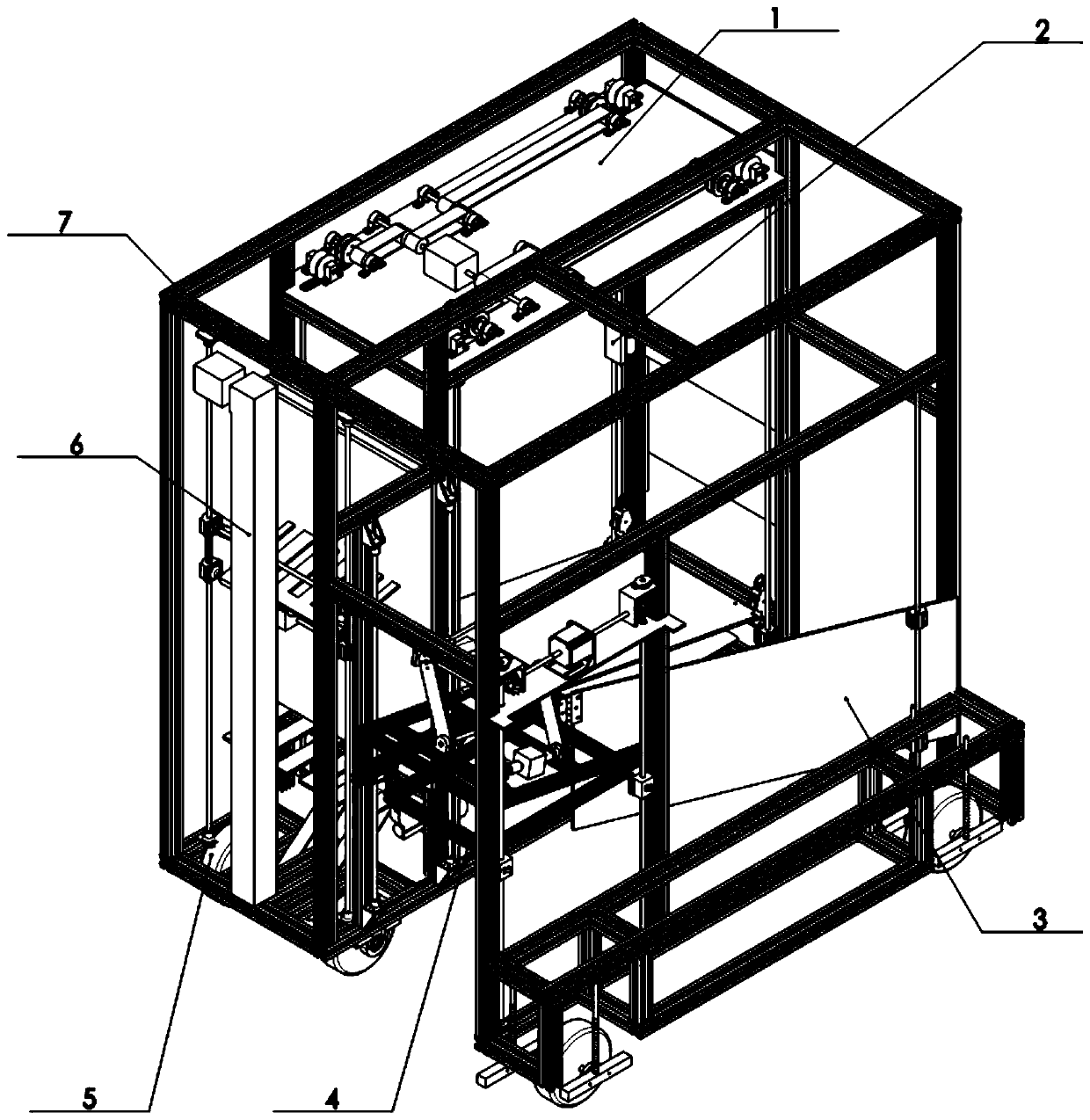

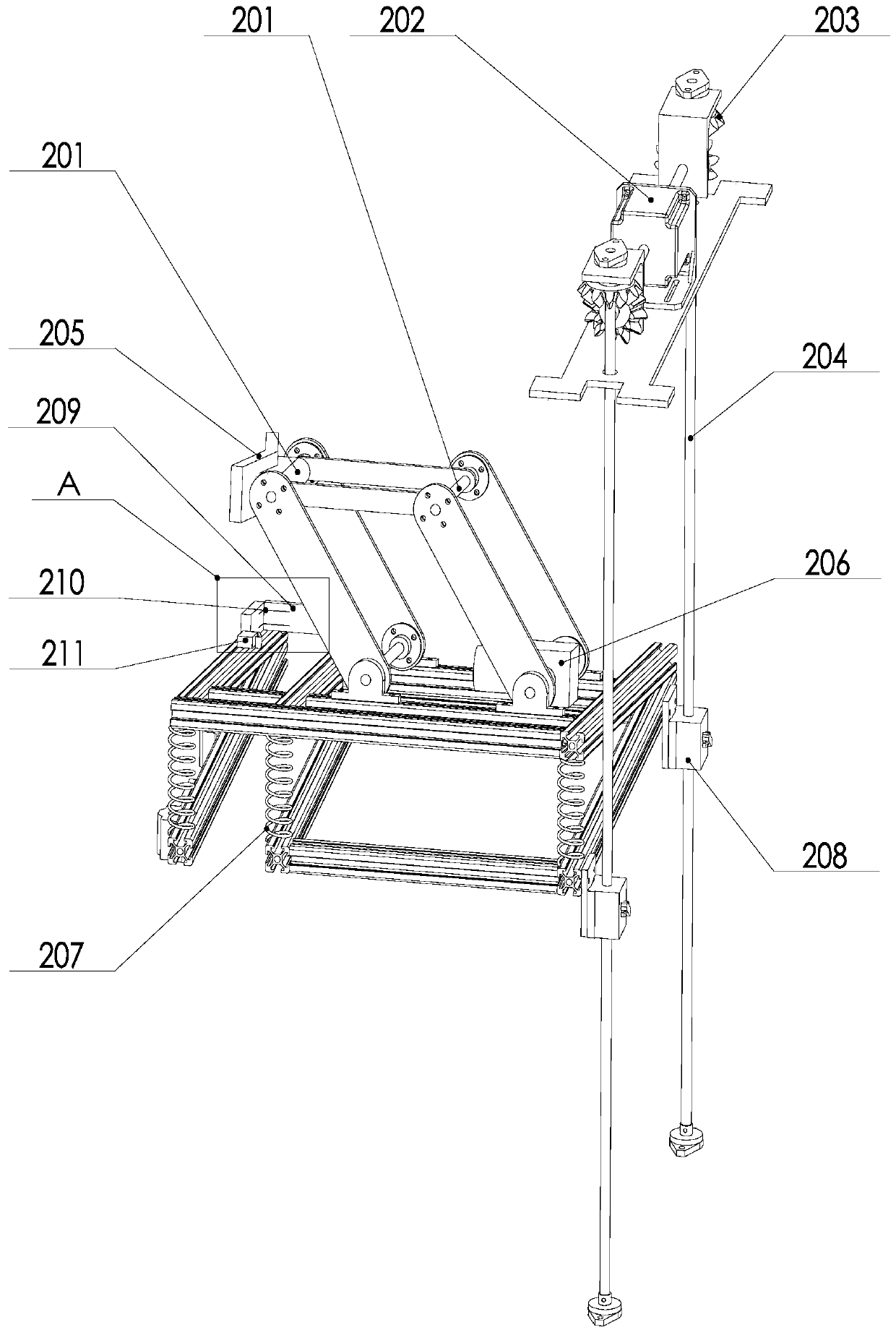

[0029] A pineapple picking machine comprises a traveling device, a picking device, a lifting device, a collecting device, an identifying device, a fruit guiding board and a frame. Wherein the identification device is a camera, which is installed on the top of the frame, and the photographing direction is the advancing direction of the overlooking picker.

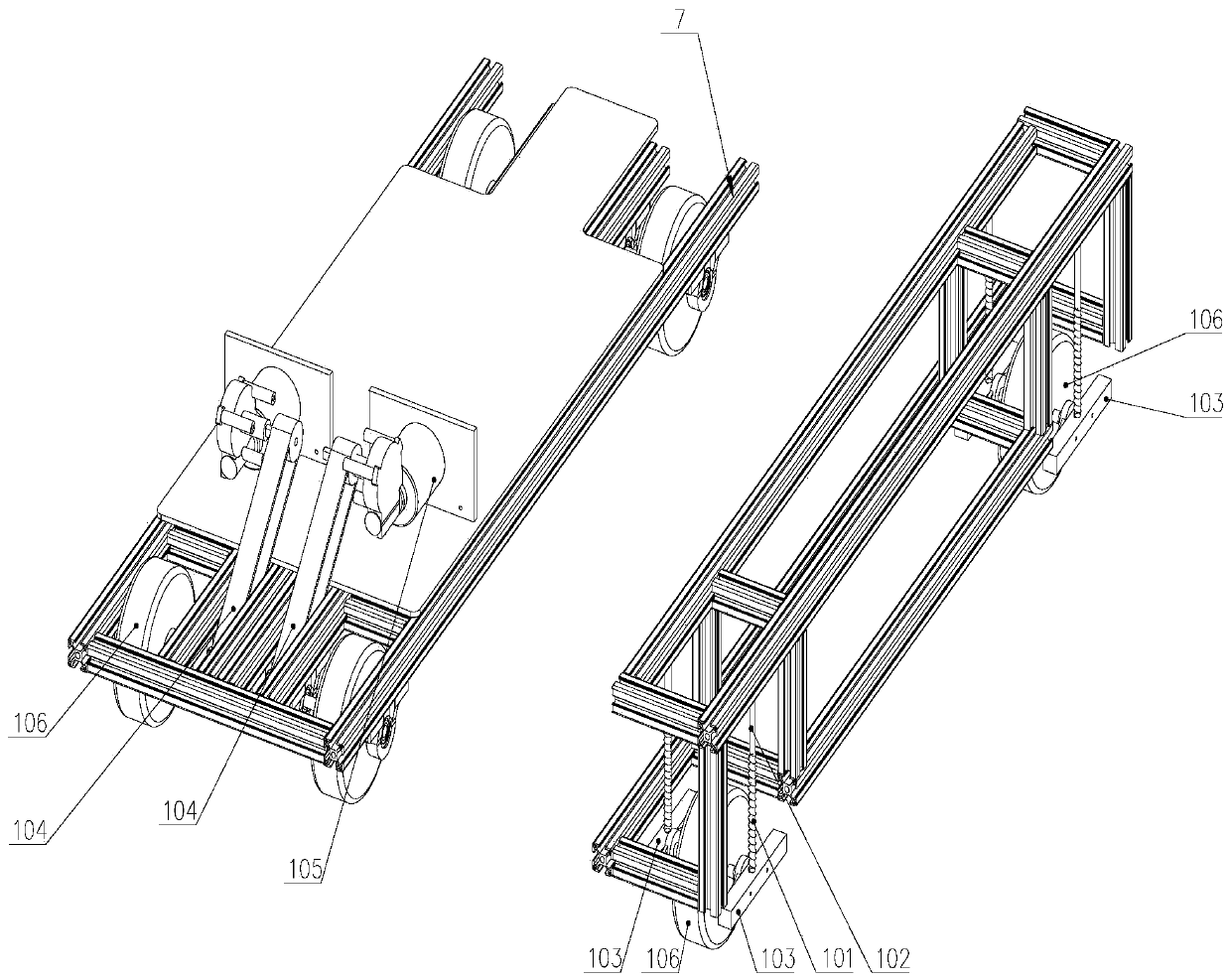

[0030] The traveling device includes: six wheels, two first motors, two synchronous belts, a fixing piece, a first limit optical axis, and a first spring. The six wheels are installed on the bottom of the frame respectively, arranged in two rows and three rows along the forward direction of the picker, and the two wheels on the left rear are driving wheels. The first motor, the synchronous belt and the driving wheel are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com