Power integrated gearbox

An integrated, gear box technology, applied in the transmission of mechanical power, wind turbines, motors and other directions that are consistent with the wind direction, can solve the problems of reducing the power collection capacity, not reaching the highest performance of the wind turbine, and increasing the rotation. Speed, high performance, the effect of increasing collection capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Attached below Figure 1-8 The present invention is further described with embodiment:

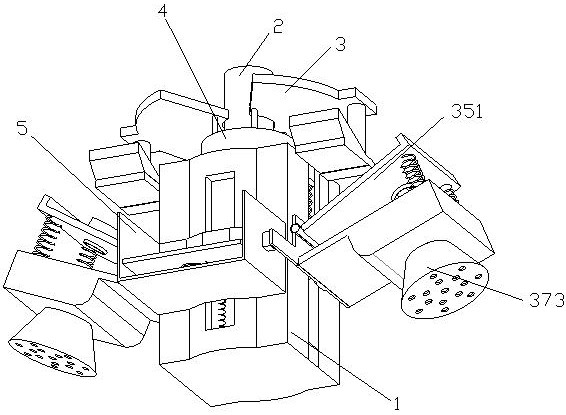

[0032] A power-integrated gearbox, comprising a body 1, the output end of the body 1 is connected with a rotating shaft 2, and one side of the rotating shaft 2 is connected with a first pushing mechanism 3; the connection between the rotating shaft 2 and the body 1 is provided with a protective mechanism 4 ; The upper end of the body 1 is connected with a second pushing mechanism 5 . A gear assembly for speed regulation is installed inside the body 1 .

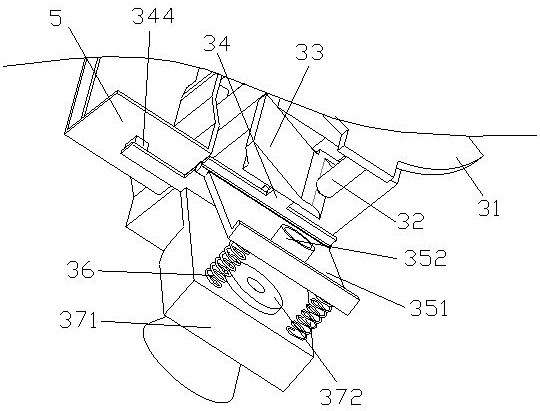

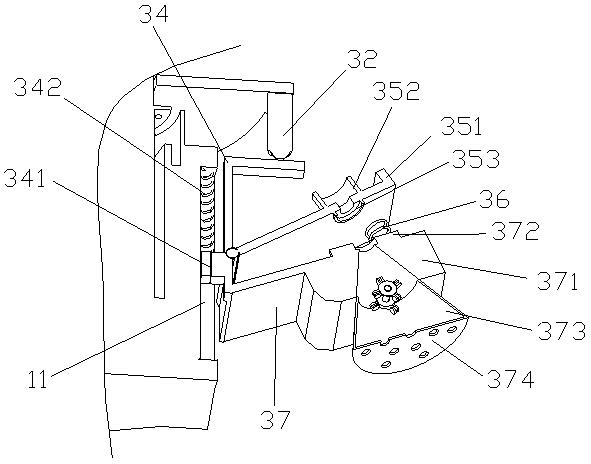

[0033]In this embodiment, the first pushing mechanism 3 includes an auxiliary fan blade 31 connected to the outer surface of the rotating shaft 2, and a push rod 32 is connected to both sides of the auxiliary fan blade 31, and one end of the push rod 32 is connected to There is a push convex plate 33, the lower part of one side of the push convex plate 33 is connected with a transmission plate 34, one side of the transmission plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com