High-speed impeller

An impeller, high-speed technology used in parts of pumping devices for elastic fluids, non-variable displacement pumps, machines/engines, etc., to reduce airflow resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Below in conjunction with specific embodiment, content of the present invention is described in further detail:

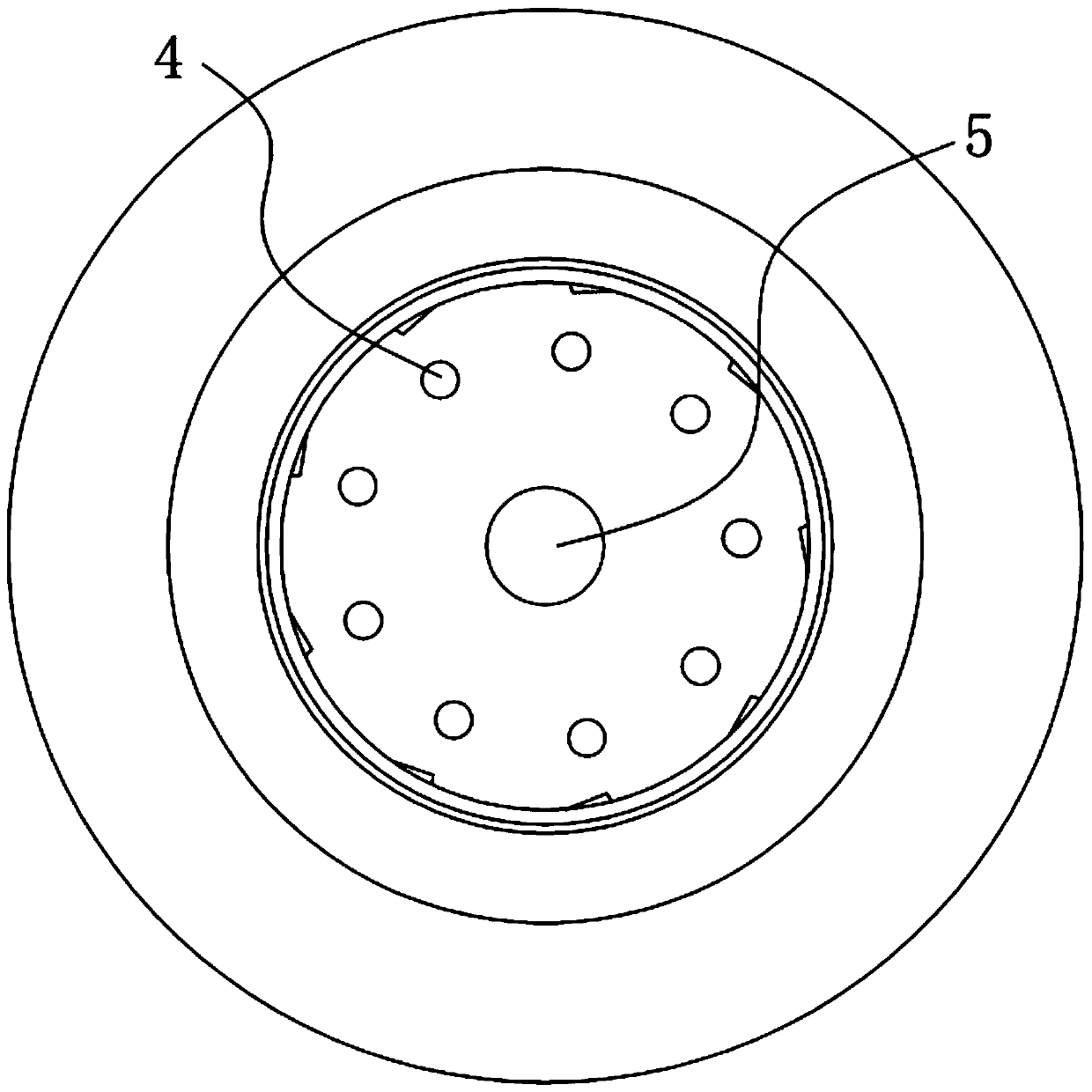

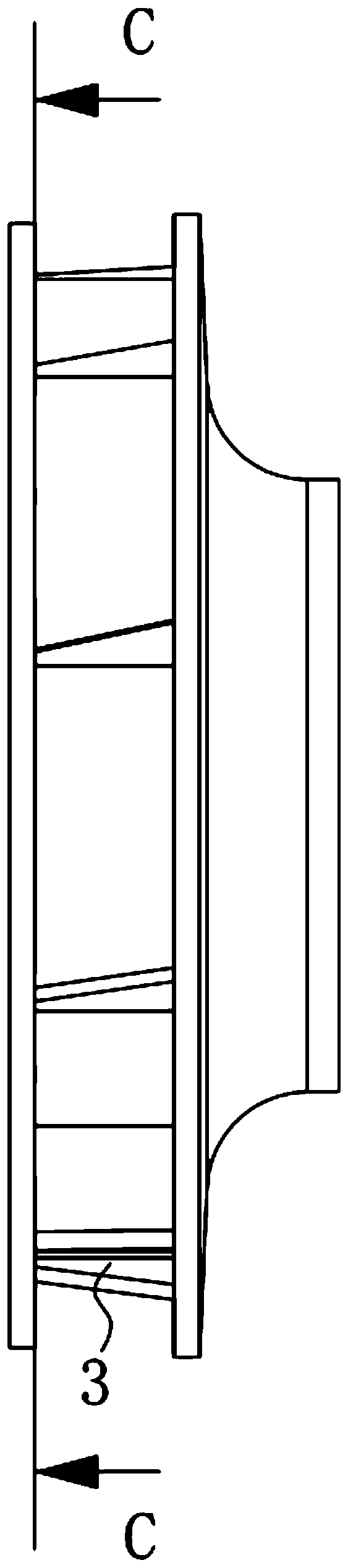

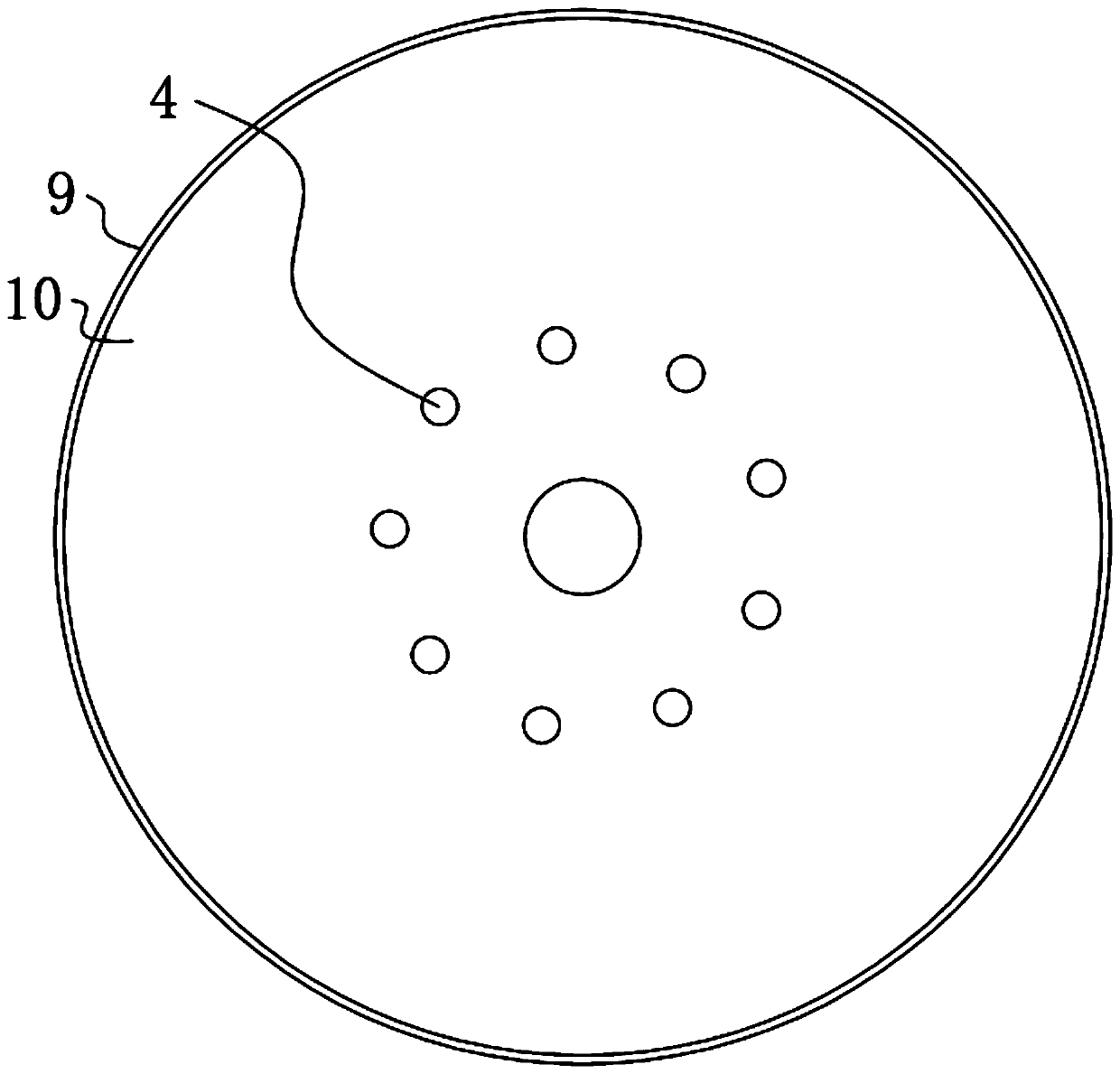

[0040] In order to achieve the purpose of the present invention, a high-speed impeller includes: an impeller body, including an upper disk 1 and a lower disk 2 coaxially arranged, and the upper disk 1 and the lower disk 2 are connected by several blades 3 in an annular array , the upper plate 1 is equipped with an air inlet 6, the lower plate 2 is fixed to the rotating motor; the pressure relief hole 4 runs through a pair of parallel surfaces of the lower plate 2, and several pressure relief holes 4 are formed around the axis of the lower plate 2 itself Annular array; skirts, including the upper skirt 9 respectively located on the edge of the upper disk part 1 and extending radially, and the lower skirt 10 extending radially along the edge of the lower disk part 2, and the blades 3 are located between the pressure relief hole 4 and the skirt between sides. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com