Cutting off recovery device for linear cutting molybdenum wires

A technology of recovery device and cutting device, which is applied in the direction of accessory devices, electric processing equipment, electrode manufacturing, etc., can solve the problems of long hours and energy of operators, and achieve the effects of improving disassembly efficiency, convenient storage, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with specific embodiments.

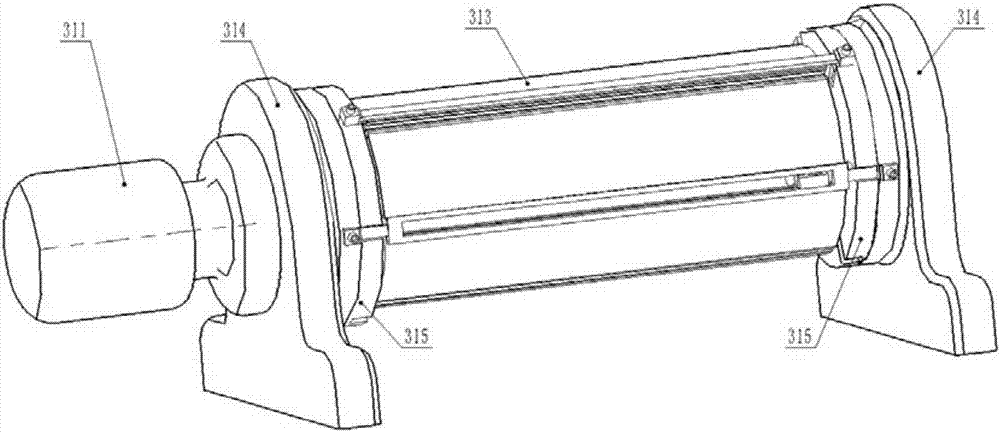

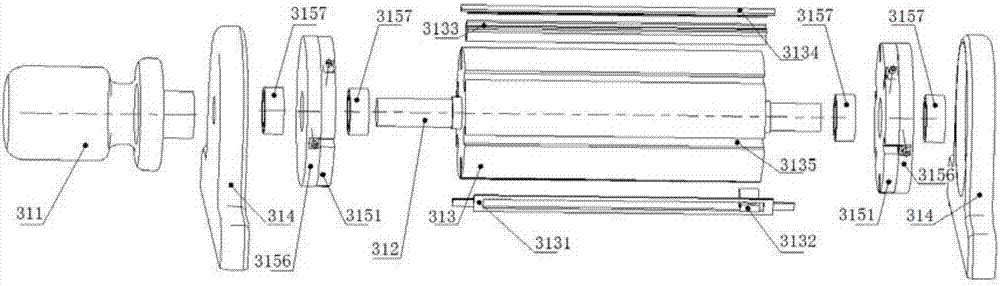

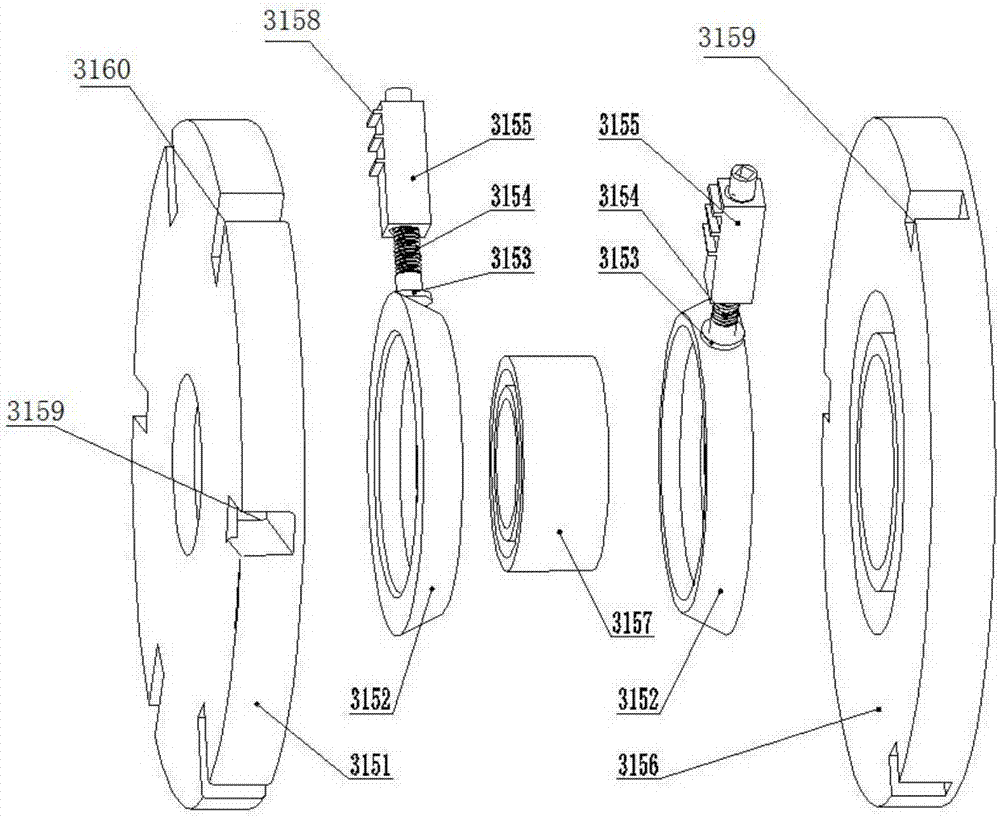

[0034] combine figure 1 , figure 2 , the present invention proposes a wire cutting molybdenum wire cutting and recovery device, which includes a wire tube 313, guide grooves 3135 uniformly distributed along the circumferential direction of the outer wall of the wire tube through the axial direction, and guide grooves 3135 spaced apart on the outer wall of the wire tube extending radially along the wire tube The cutting devices respectively arranged in the direction and the wire receiving devices arranged in the guide grooves 3135 between adjacent cutting devices; Cooperating with the guide groove 3135, the molybdenum wire wound on the wire drum 313 can be cut off. The wire receiving device is sleeved with a pressing device for pressing and cutting the electrode wire in the axial direction of the wire drum. Both ends of the barrel 313 are symmetrically provided ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com