Automatic screening machine suitable for LED product detection

A screening machine and product technology, applied in the field of screening machines, can solve the problems of being unable to passively control the neat arrangement, unable to control the guiding arrangement, and unable to take out the products at the same time, so as to achieve the effect of smooth movement and convenient extraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

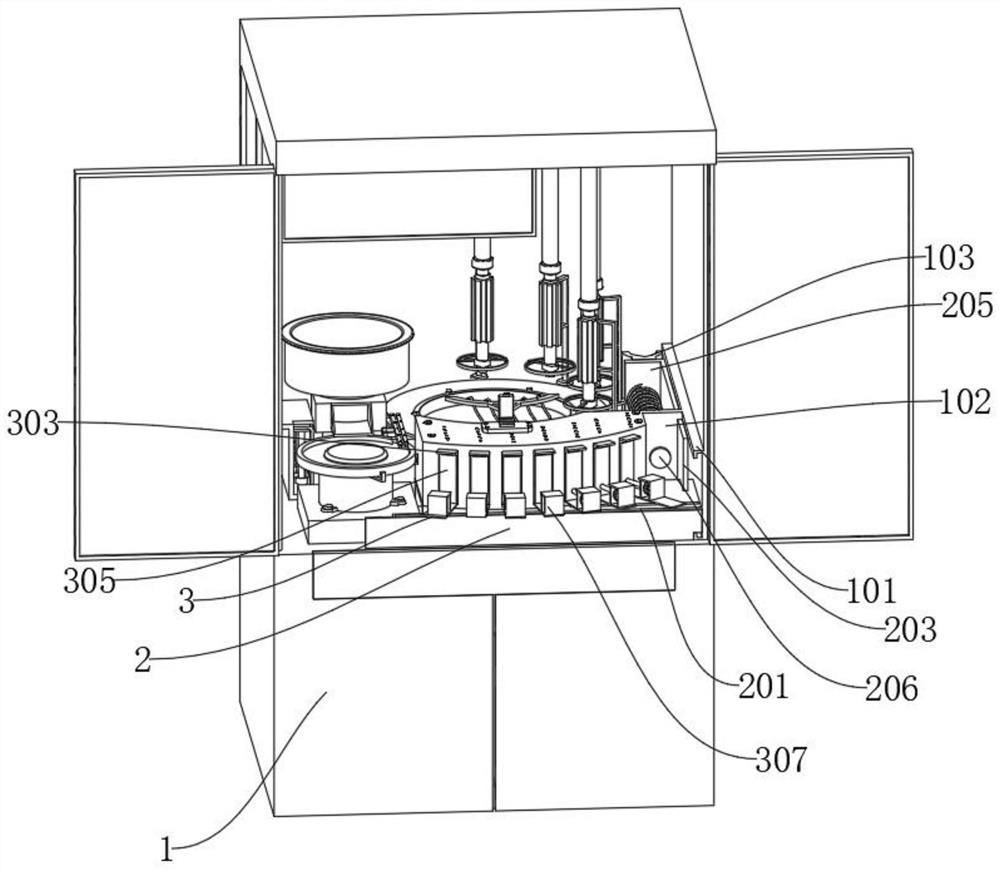

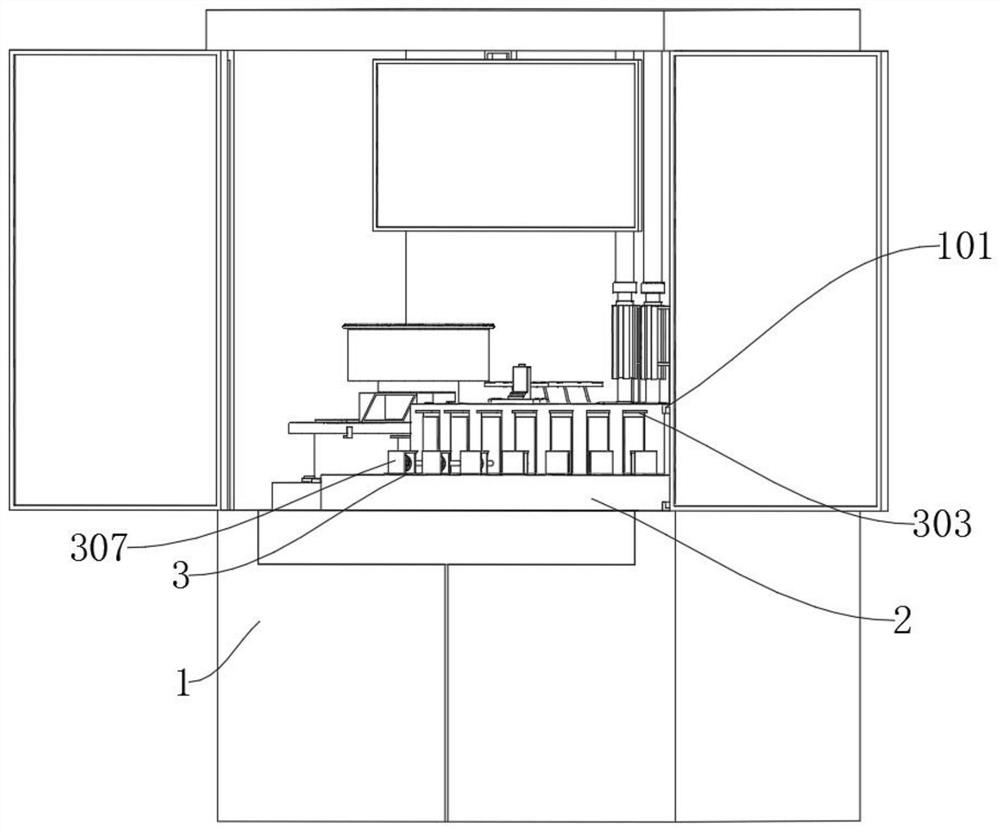

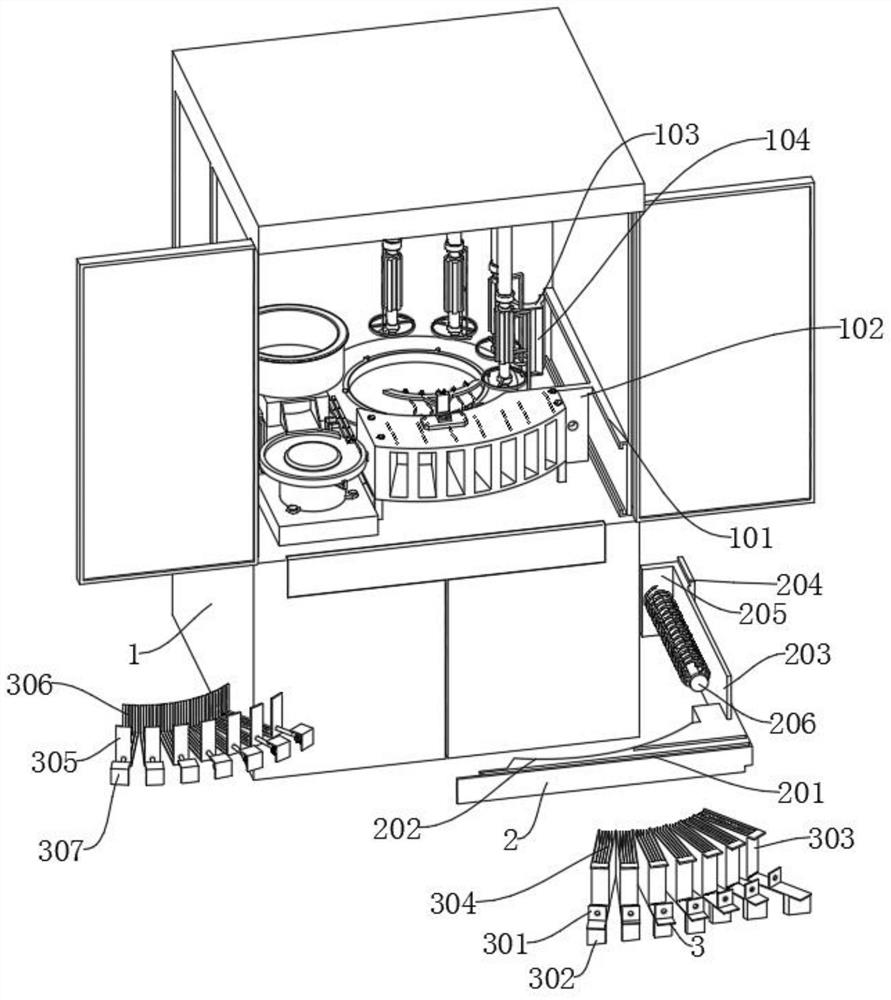

[0028] as attached figure 1 to attach Figure 8 Shown:

[0029] The invention provides an automatic screening machine suitable for LED product detection, which includes a main body 1; the main body 1 is the body of the automatic screening machine, the main body 1 is a rectangular structure, and a puller 2 is installed on the bottom of the front end of the main body 1; the puller 2, the puller 2 is an L-shaped plate-shaped structure, and the pulling part 2 plays the role of driving the control board 3 to move together, and then conveniently takes out the storage part 303, and the top of the pulling part 2 is equipped with the control board 3; the control board 3, the control board 3 includes Leveling mechanism, the inner end of the control panel 3 is connected with a leveling mechanism, the control panel 3 is a rectangular plate structure, the control panel 3 plays the role of driving the storage parts 303 to be installed together, and then it is convenient to collect the prod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com