Method for using cloth hanging and cooling machine

A cloth cooling machine and hanging cloth technology, applied in the direction of winding strips, function indication, thin material processing, etc., can solve the problems of uncoordinated cloth pulling speed, inconvenient production and work, crepe marks, hand marks, etc., to achieve guaranteed Improve product quality, improve production efficiency, and facilitate neat packaging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0089] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

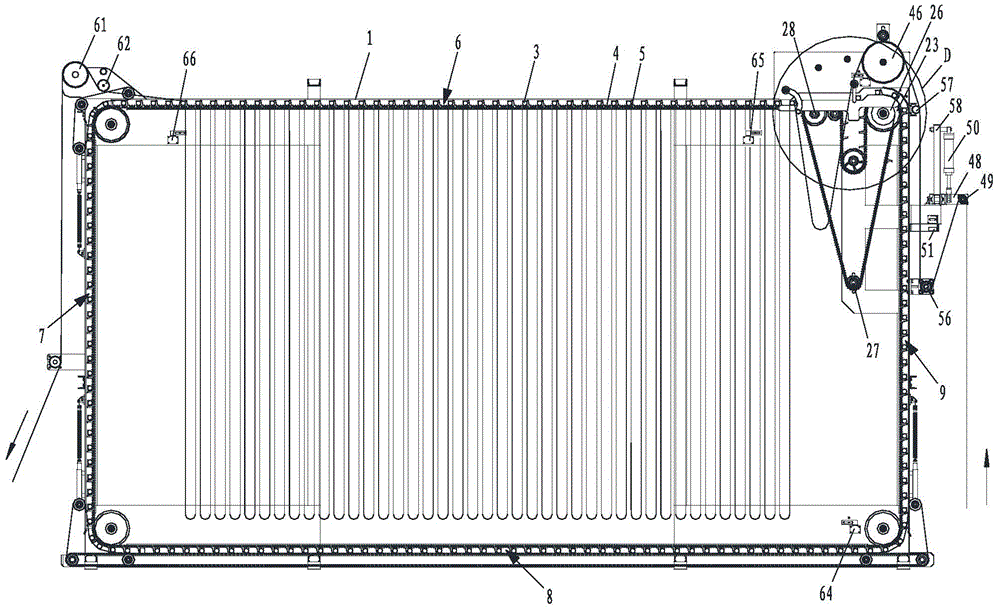

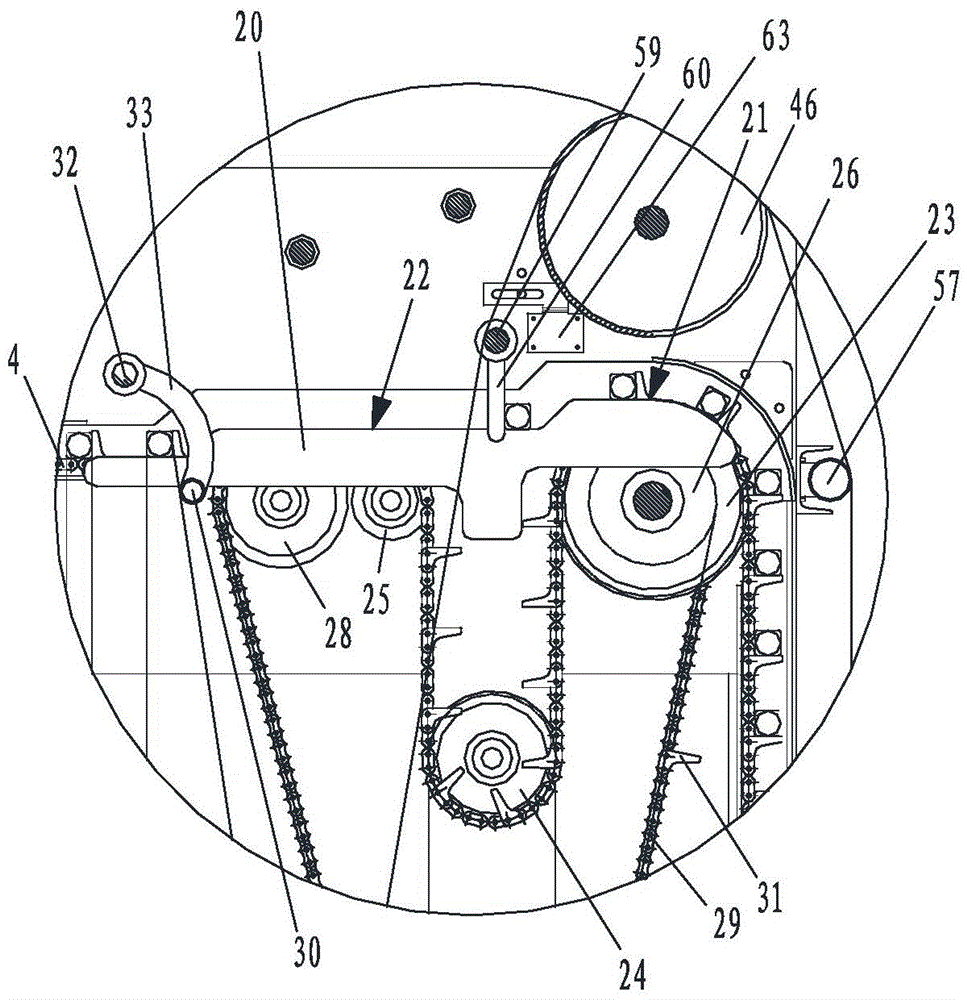

[0090] combine figure 1 with figure 2 As shown, the fully automatic hanging cloth and cooling cloth machine, including the rack. The rack is square and includes a left wall panel 1 and a right wall panel 2.

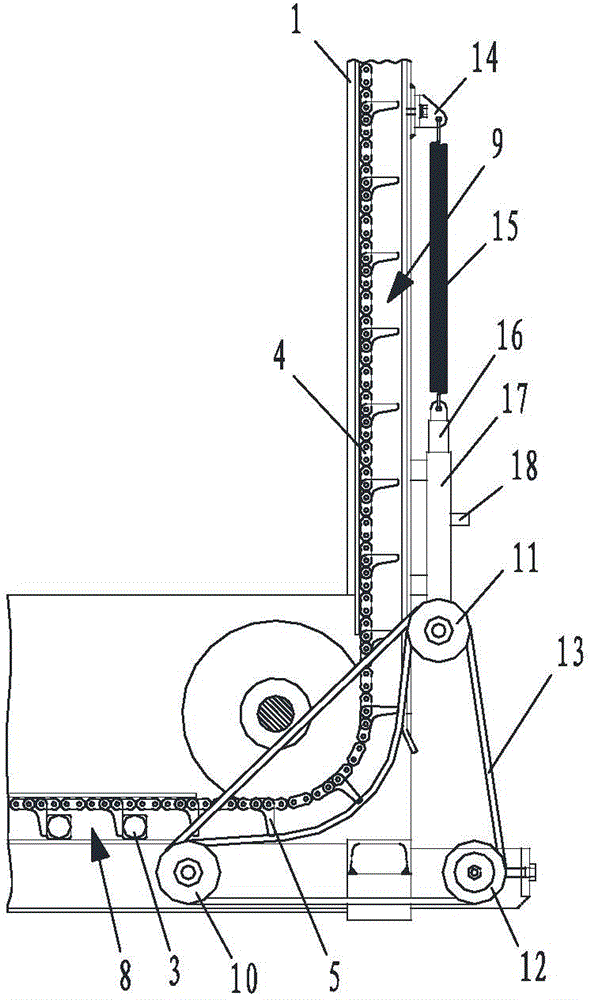

[0091] A circular guide rail is respectively arranged on the left side wallboard 1 and the right side wallboard 2, and a circular conveying chain is arranged inside each circulating guide rail, and a plurality of first lever teeth are arranged on each circulating conveying chain.

[0092] Cloth hanging rod 3 is arranged on the inside of two circulating guide rails across.

[0093] Such as figure 1 As shown, a circular guide rail is set on the left wallboard 1, a circular conveying chain 4 is arranged inside the circulating guide rail, and a plurality of first lever teeth 5 are arranged on the circular conveying chain 4.

[0094] The c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com