Automatic grading and encasement packaging system for solar cell modules

A solar cell, automatic binning technology, applied in packaging, packaging machines, transportation and packaging, etc., can solve the problems of unstable packing quality, high work intensity of employees, secondary damage to products, etc., to reduce the work intensity of employees, The effect of saving labor costs and improving sorting accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

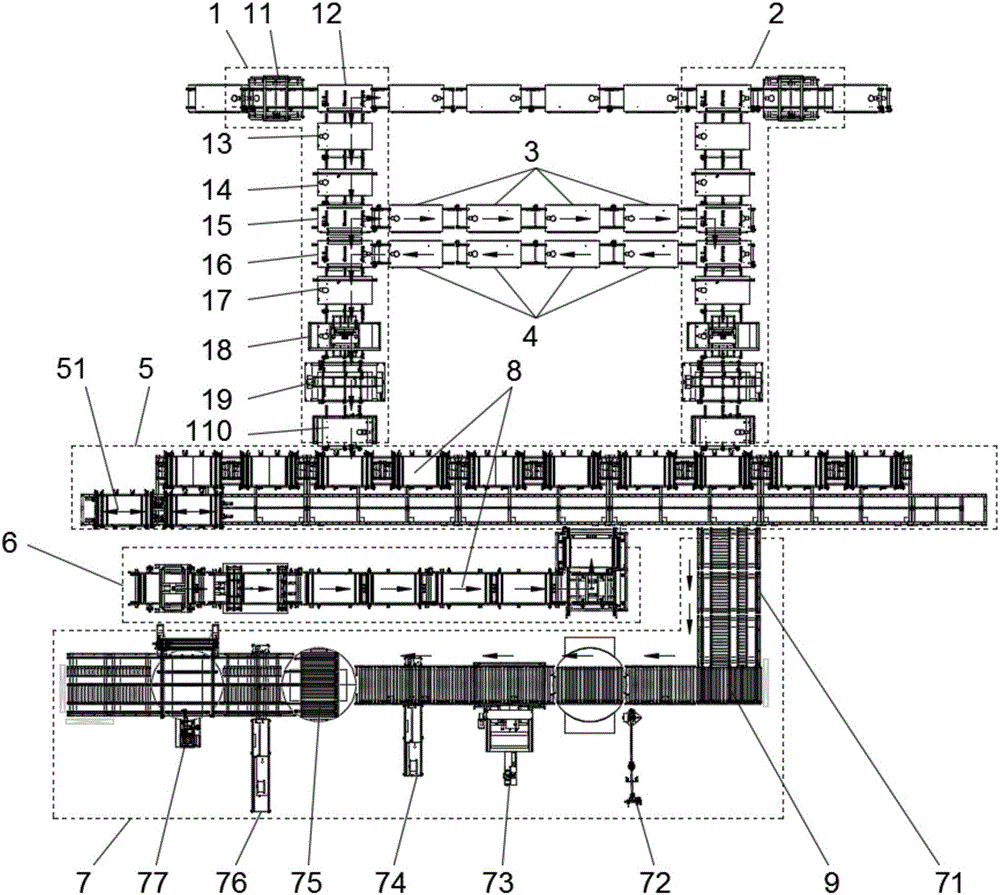

[0017] Such as figure 1 As shown, the automatic binning and packaging system for solar cell modules includes the first feeding and sorting line 1, the second feeding and sorting line 2, the first feeding and the second feeding working line 3, the second feeding and sorting line The second feeding is transferred to the first feeding work line 4, the stack insertion and transfer work line 5, the empty stack loading work line 6 and the full stack unloading work line 7; wherein, the first feeding and sorting work line 1 is composed of 90-degree conveying steering unit 12, first code-reading and grading unit 13, second code-reading and grading unit 14, grading transfer unit 15, confluence conveying unit 16, conveying unit 17, horizontally reversible 180-degree unit 18, Composed of a turning unit 19, a normalizing unit 110 and a control system; the second feeding and sorting work line 2 and the first feeding and sorting working line 1 are mirror images of each other; the first feedi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com