Surface self-cleaning carbon nitride Fenton-photocatalytic nanofiltration membrane and preparation method thereof

A carbon nitride-based, photocatalytic technology, applied in the direction of chemical instruments and methods, membranes, membrane technology, etc., can solve problems such as difficulty in forming a homogeneous membrane, difficulty in eliminating membrane pollution, etc., achieve mild operating conditions, and improve anti-pollution performance , the effect of simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Embodiment 1, preparation of the Fenton-photocatalytic nanofiltration membrane based on carbon nitride and iron-containing Fenton reagent

[0048] A method for preparing a Fenton-photocatalytic nanofiltration membrane based on carbon nitride and iron-containing Fenton reagents, the method comprising the following steps:

[0049] Step 1: Using melamine as a nitrogen-containing precursor, thermal polymerization was carried out in a high-temperature furnace at 550° C. for 4 hours to prepare graphite-phase carbon nitride.

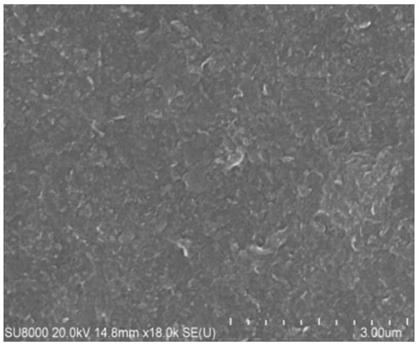

[0050] Step 2: Disperse the graphene carbon nitride in step 1 in an isopropanol solvent, use an ultrasonic device to perform liquid phase stripping, and centrifuge at a high speed of 5000 rpm for 10 minutes to remove the bulk phase that has not been fully stripped carbon nitride to obtain well-dispersed carbon nitride nanosheets as a film-forming solution.

[0051] Step 3: Prepare a Fenton-like reaction precursor solution by using ferric chloride and ph...

Embodiment 2

[0056] Embodiment 2, preparation of the Fenton-photocatalytic nanofiltration membrane based on carbon nitride and iron-containing Fenton reagent

[0057] A method for preparing a Fenton-photocatalytic nanofiltration membrane based on carbon nitride and iron-containing Fenton reagents, the method comprising the following steps:

[0058] Step 1: Urea is used as a nitrogen-containing precursor, and thermal polymerization is carried out in a high-temperature furnace at 550° C. for 4 hours to prepare graphite-phase carbon nitride.

[0059] Step 2: The graphene carbon nitride in step 1 is subjected to molecular tailoring in a concentrated sodium hydroxide solution, the reaction solution is treated by dialysis to remove impurity ions, and the solution after dialysis is centrifuged at 1500 rpm for 10 Minutes, a well-dispersed carbon nitride sol was obtained as a film-forming solution.

[0060] Step 3: Prepare a Fenton-like reaction precursor solution with ferric chloride and phosphot...

Embodiment 3

[0065] Embodiment 3, preparation of Fenton-like photocatalytic nanofiltration membrane based on carbon nitride and iron-containing Fenton reagent

[0066] A method for preparing a Fenton-photocatalytic nanofiltration membrane based on carbon nitride and iron-containing Fenton reagents, the method comprising the following steps:

[0067] Step 1: Using melamine as a nitrogen-containing precursor, thermal polymerization was carried out in a high-temperature furnace at 550° C. for 4 hours to prepare graphite-phase carbon nitride.

[0068] Step 2: The graphene carbon nitride in step 1 is subjected to molecular tailoring in a concentrated sodium hydroxide solution, the reaction solution is treated by dialysis to remove impurity ions, and the solution after dialysis is centrifuged at 1500 rpm for 10 Minutes, a well-dispersed carbon nitride sol was obtained as a film-forming solution.

[0069] Step 3: Using ferric chloride as the Fenton-like reagent precursor, mix the carbon nitride ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com