Method for adsorbing chromium and iron ions in industrial ferrochrome ore liquid through ion exchanging resin.

A technology of ion exchange resin and cation exchange, which is applied in the field of adsorbing chromium iron ions and iron ions in industrial chromite liquid, using ion exchange resin to adsorb chromium in industrial chromite liquid, and the treatment field of industrial chromite liquid, which can solve the problem. The adsorption of chromite liquid has not seen reports and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Industrial chromite liquid: simulated industrial chromite liquid prepared by selective acid solution, in which the concentration of chromium ion is 13.28 mg / mL, and the concentration of iron ion is 13.05 mg / mL.

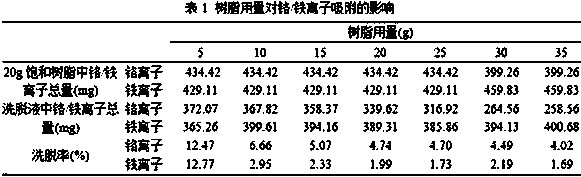

[0038]Adsorption of chromium and iron: put 35g of resin (001×7 cation exchange resin) in a 250 mL Erlenmeyer flask, and then add 25 mL of chromite solution. Shake at room temperature (130 r min -1 ) for 45 min, and after reaching adsorption equilibrium, the obtained solution was centrifuged at 8000 rpm, and the contents of chromium and iron ions in the filtrate were determined to be 8.20 mg / mL and 9.76 mg / mL, respectively.

[0039] Elution of chromium and iron: desorption after resin adsorption reaches saturation. Weigh 20g of saturated resin and use 30mL of 10% ammonium sulfate solution as the eluent. -1 Oscillate at a constant temperature shaker for 2 hours, collect the eluent, and measure the contents of chromium and iron ions in the solution to be 1.42 mg...

Embodiment 2

[0041] Industrial chromite liquid: simulated industrial chromite liquid prepared by selective acid solution, in which the concentration of chromium ion is 13.28 mg / mL, and the concentration of iron ion is 13.05 mg / mL.

[0042] Adsorption of chromium and iron: put 70g of resin (001×7 cation exchange resin) in a 250 mL Erlenmeyer flask, and then add 50 mL of chromite solution. Shake at room temperature (120 r min -1 ) for 45 min, and after reaching adsorption equilibrium, the obtained solution was centrifuged at 6000 rpm, and the contents of chromium and iron ions in the filtrate were determined to be 9.47 mg / mL and 9.56 mg / mL, respectively.

[0043] Elution of chromium and iron: desorption after resin adsorption reaches saturation. Weigh 20g of saturated resin and use 30mL of 10% ammonium sulfate solution as the eluent. -1 Oscillate at a constant temperature shaker for 2 hours, collect the eluate, and measure the contents of chromium and iron ions in the solution to be 0.92 m...

Embodiment 3

[0045] Industrial chromite liquid: choose acid-soluble industrial chromite liquid, in which the concentration of chromium ion is 13.28 mg / mL, and the concentration of iron ion is 13.05 mg / mL.

[0046] Adsorption of chromium and iron: put 35g of resin (001×7 cation exchange resin) in a 500 mL Erlenmeyer flask, and then add 25 mL of chromite solution. Shake at room temperature (100 r min -1 ) for 45 min, and after reaching adsorption equilibrium, the obtained solution was centrifuged at 7000 rpm, and the contents of chromium and iron ions in the filtrate were determined to be 8.99 mg / mL and 9.70 mg / mL, respectively.

[0047] Elution of chromium and iron: desorption after resin adsorption reaches saturation. Weigh 20 g of saturated resin, use 30 mL of pure water as eluent, -1 Oscillate at a constant temperature shaker for 2 hours, collect the eluent, and measure the contents of chromium and iron ions in the solution to be 0.99 mg / mL and 0.70 mg / mL, respectively. It can be calc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com