Preparation and detection method of ultralow carbon aluminum carbon fireproof material

A technology of aluminum-carbon refractory material and detection method, which is applied in the direction of analyzing materials, material thermal development, material analysis using wave/particle radiation, etc., can solve the problems of thermal shock resistance and slag erosion resistance of refractory products, etc. Achieve the effect of improving thermal shock resistance and slag corrosion resistance, which is beneficial to mass production, and has good thermal shock resistance and slag resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

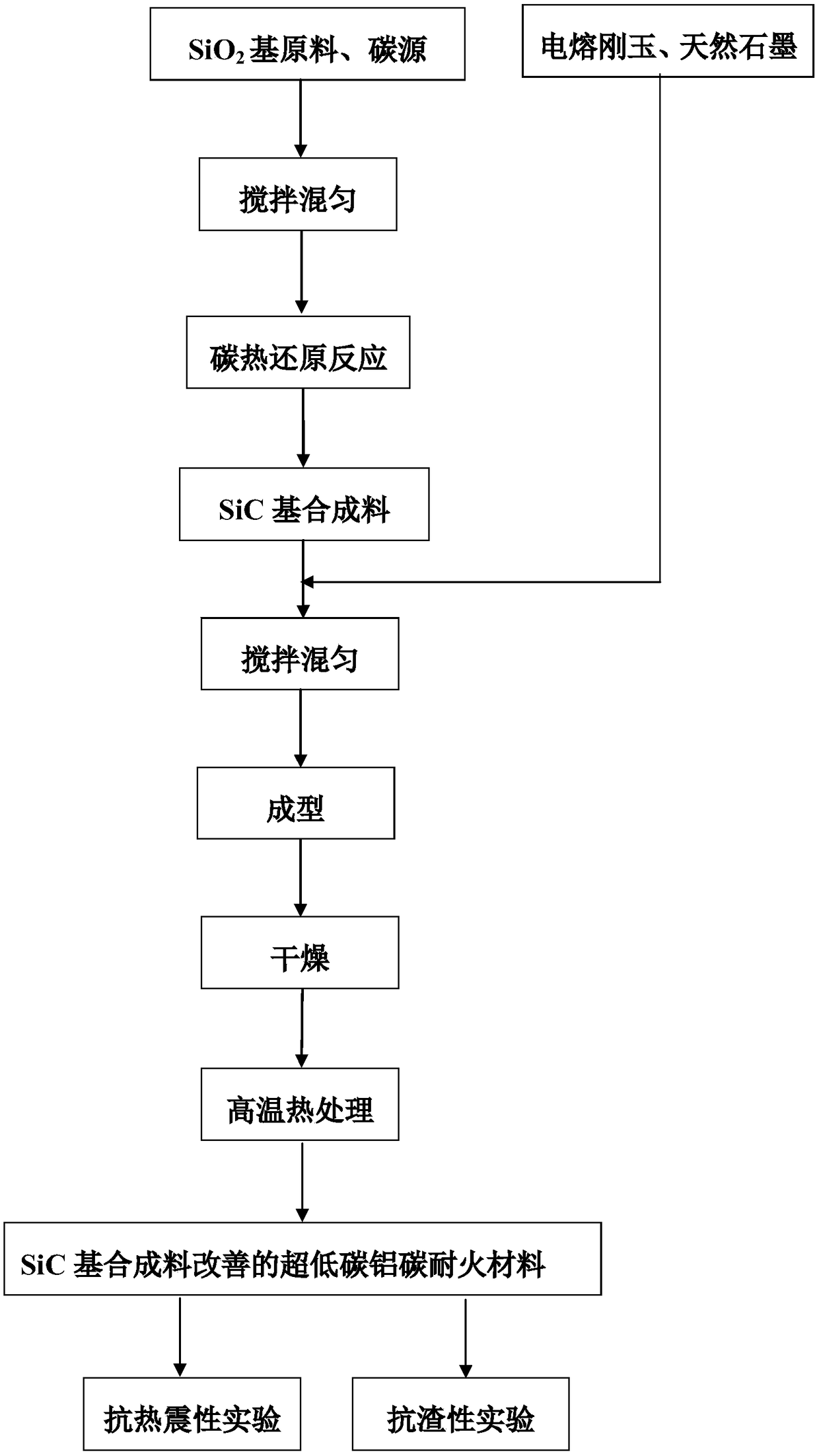

[0040] A method for preparing and detecting an ultra-low-carbon aluminum-carbon refractory material, comprising the following steps:

[0041] Step 1. SiC-Al 2 o 3 Synthesis of composite micropowder:

[0042] (1) pyrophyllite and carbon black are weighed according to the mass ratio of 1000:200, and stirred and mixed;

[0043] (2) Put the mixed raw materials into a high-temperature furnace, heat at 1650°C for 4 hours, and carry out carbothermal reduction reaction under argon to synthesize SiC-Al 2 o 3 Composite micropowder;

[0044] (3) SiC-Al 2 o 3 The composite micropowder is kept at 700°C for 2 hours in air to remove excess carbon;

[0045] Step 2, SiC-Al 2 o 3 Preparation and thermal shock resistance test of improved ultra-low carbon aluminum-carbon refractory samples:

[0046] (1) Fused corundum, natural graphite, SiC-Al 2 o 3 The composite micropowder is weighed according to the mass ratio of 930:20:50, and the liquid phenolic resin of 1% (mass fraction) of the...

Embodiment 2

[0060] A preparation and detection method of an ultra-low-carbon aluminum-carbon refractory material, the same as in Example 1, except that:

[0061] (1) Pyrophyllite and carbon black used in step 1(1) are changed into fly ash and gac, and its mass proportion is 1000:500;

[0062] (2) Preparation of SiC-Al in step 1(2) 2 o 3 The temperature of the composite micropowder is 1600°C;

[0063] After testing, the main crystal phases of the obtained composite micropowder are β-SiC, α-Al 2 o 3 , also contains a small amount of FeSi; the particle size of the micropowder is about 1 μm. Adding it to ultra-low carbon aluminum-carbon refractory materials, it is found that the thermal shock resistance and slag resistance of the refractory products are better. The number of thermal shock cycles is 15, the strength retention rate is 40.6%, and the thickness of the erosion layer is 0.8mm.

Embodiment 3

[0065] A preparation and detection method of an ultra-low-carbon aluminum-carbon refractory material is the same as in Example 1, except that the raw materials for preparing the SiC-based synthetic material are coal gangue and carbon black, and the mass ratio is 1000:400.

[0066] After testing, the resulting SiC-Al 2 o 3 The main crystal phases of composite micropowder are β-SiC, α-Al 2 o 3 ; The particle size of the micropowder is about 1 μm. Adding it to ultra-low carbon aluminum-carbon refractory materials, it is found that the thermal shock resistance and slag resistance of the refractory products are better. The number of thermal shock cycles is 18, the strength retention rate is 45.6%, and the thickness of the erosion layer is 0.5mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com