High-temperature-resistant ceramic brake pad and production process thereof

A production process and technology of brake pads, applied in the direction of friction linings, other chemical processes, mixers, etc., can solve the problem of unpredictable high temperature resistance of ceramic brake pads, and achieve excellent sound absorption, low density, and good impact resistance intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A high temperature resistant ceramic brake pad, such as Figure 5 As shown, it includes a steel back 21, the top outer wall of the steel back 21 is provided with a sound-absorbing sheet 22, and the top outer wall of the sound-absorbing sheet 22 is bonded with a heat insulating layer 23, and the top outer wall of the heat insulating layer 23 is provided with a friction material 24.

[0032] The friction material 24 includes the following raw materials by weight: 5-7 parts of sepiolite fiber, 10-15 parts of asbestos fiber, 6-8 parts of potassium carbonate whisker, 1-2 parts of brass fiber, wollastonite 4-5 parts, 4-8 parts of aramid fiber, 10-15 parts of aluminum silicate fiber, 3-7 parts of corundum, 5-8 parts of zircon, 2-3 parts of cryolite, 2-3 parts of feldspar, 7-9 parts of vermiculite, 8-9 parts of graphite, 1-4 parts of antimony disulfide, 5-7 parts of talc, 2-4 parts of mica, 6-8 parts of barite, 5-6 parts of foamed iron powder, 6-7 parts of boron modified pheno...

Embodiment 2

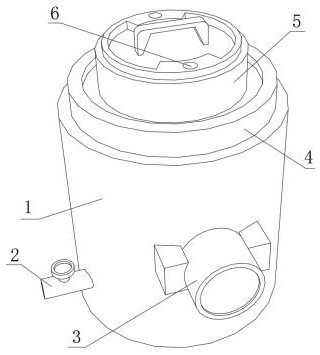

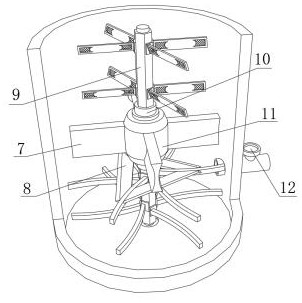

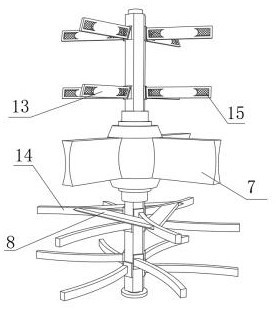

[0040] A production process of high temperature resistant ceramic brake pads, such as Figure 1-4As shown, in order to promote the uniform mixing of raw materials; this embodiment adds a mixing device on the basis of embodiment 1, including a main body box 1, a discharge pipe 2, a heat preservation cover 4, a feeding cylinder 5 and two exhaust Hole 6, the front outer wall of the main body box 1 is fixed with a motor 3 through a bracket, and the output shaft coupling of the motor 3 is connected with a mixing mechanism, the main body box 1, the heat preservation cover 4 and the feeding cylinder 5 are therefore connected to each other through a sealing ring , the discharge pipe 2 is connected to the side of the main body box 1 by threads, the top outer wall of the discharge pipe 2 is fixed with a valve 12 by threads, and the two exhaust holes 6 are respectively opened on the outer walls of both sides of the top of the feed cylinder 5; use , open the feeding cylinder 5, pour the v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com