Braking material for medium and low-speed maglev trains and preparation method thereof

A technology for magnetic levitation trains and braking materials, applied in mechanical equipment, metal processing equipment, gear transmission mechanisms, etc., can solve the problems of low friction coefficient, short material life, poor matching, etc., achieve high heat capacity, reduce apparent hardness, Effect of improving load resistance performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

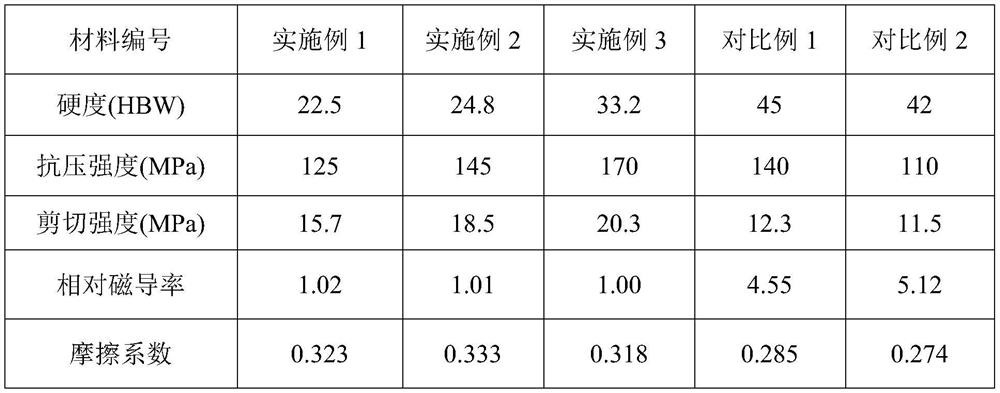

Embodiment 1

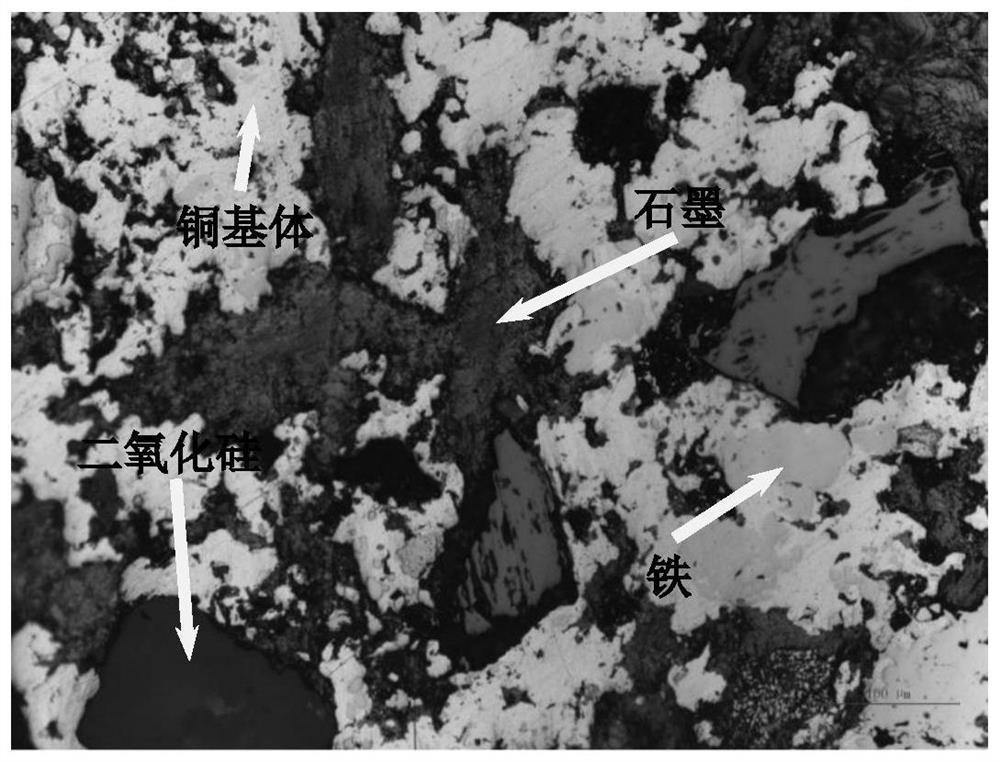

[0041] The component weight percentages of the brake material for the middle and low speed maglev trains of the present embodiment: 50% of copper powder, 4% of zinc powder, 4% of aluminum powder, 3% of molybdenum powder, 1% of tungsten disulfide powder, 18% of graphite powder, Magnesia powder 9%, zirconia powder 11%.

[0042] According to the weight percentage of each component and the total weight of the ingredients, weigh the copper powder, molybdenum powder and tungsten disulfide powder, mix well, and sieve through a 200-mesh standard sieve for premixing. According to the weight percentage of each component and the total weight of the ingredients, the remaining raw materials of all the components are weighed and poured into the above-mentioned premixed material. Add kerosene with a weight of 1.5% of the total weight of the ingredients into all the raw materials that have been batched, and then mix the powder well, put the powder into a three-dimensional mixer and mix for 6 ...

Embodiment 2

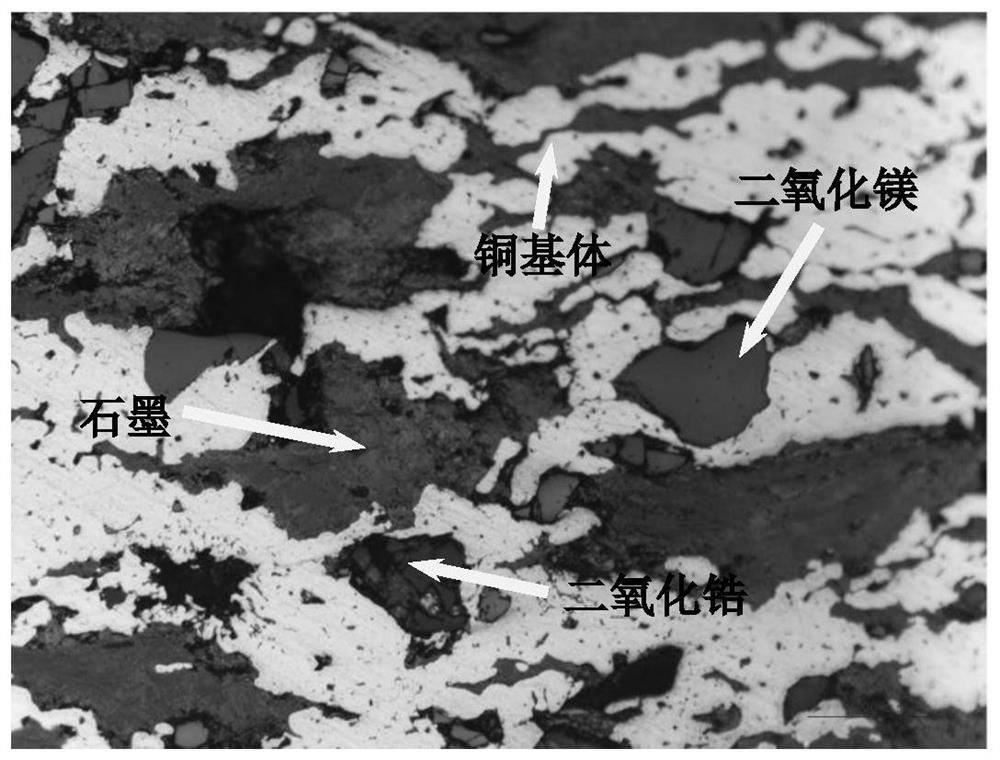

[0044] The component weight percentages of the brake material for the middle and low speed maglev trains of the present embodiment: 57% of copper powder, 6% of zinc powder, 1% of aluminum powder, 4% of molybdenum powder, 4% of tungsten disulfide powder, 10% of graphite powder, Magnesia powder 6%, zirconia powder 12%.

[0045] According to the weight percentage of each component and the total weight of the ingredients, weigh the copper powder, molybdenum powder and tungsten disulfide powder, mix well, and sieve through a 200-mesh standard sieve for premixing. According to the weight percentage of each component and the total weight of the ingredients, the remaining raw materials of all the components are weighed and poured into the above-mentioned premixed material. Add kerosene with a weight of 0.8% of the total weight of the ingredients into all the raw materials that have been prepared, and then mix the powder evenly, then put the powder into a three-dimensional mixer and mi...

Embodiment 3

[0047] The component weight percentages of the brake material for the middle and low speed maglev trains of the present embodiment: 65% of copper powder, 1% of zinc powder, 5% of aluminum powder, 1% of molybdenum powder, 2% of tungsten disulfide powder, 11% of graphite powder, Magnesia powder 10%, zirconia powder 5%.

[0048] According to the weight percentage of each component and the total weight of the ingredients, weigh the copper powder, molybdenum powder and tungsten disulfide powder, mix well, and sieve through a 200-mesh standard sieve for premixing. According to the weight percentage of each component and the total weight of the ingredients, the remaining raw materials of all the components are weighed and poured into the above-mentioned premixed material. Add kerosene with a weight of 1.0% of the total weight of the ingredients into all the raw materials that have been batched, and then mix the powder evenly. Put the powder into a three-dimensional mixer and mix for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com