Preparation method and application of carbon-ceramic friction material

A friction material, carbon ceramic technology, applied in the direction of friction linings, brake parts, brake discs, etc., can solve the problems of reduced creep resistance, brittle composite materials, high porosity of composite materials, and achieve stable friction coefficient. , the effect of improving mechanical properties and high friction coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

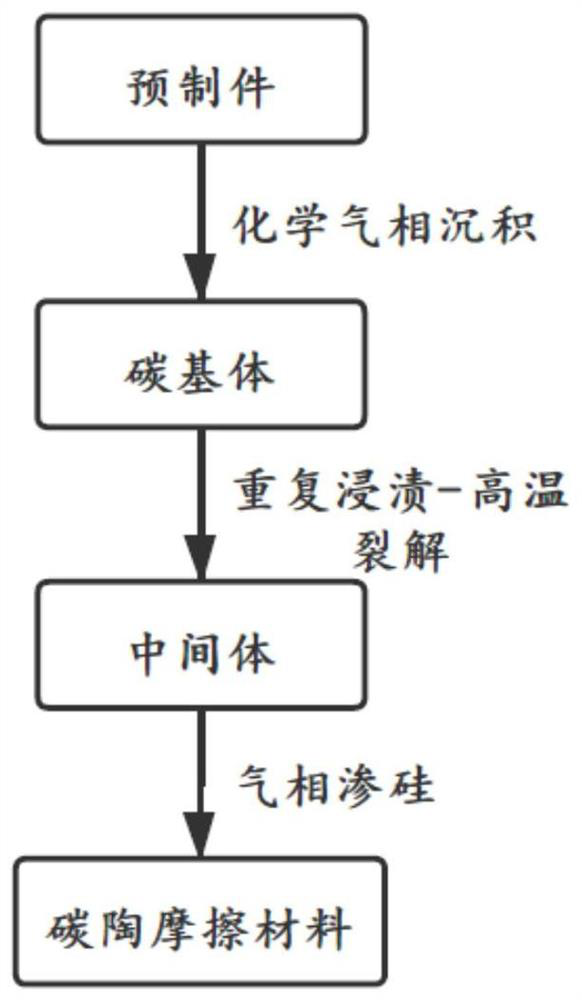

[0030] Embodiment 1 of the present invention provides a method for preparing a carbon-ceramic friction material, comprising the following steps:

[0031] A) Obtain a prefabricated part made of carbon fiber;

[0032] B) using propylene as the carbon source gas and argon as the carrier gas, depositing and densifying the preform by using a chemical vapor deposition infiltration process to prepare a carbon matrix;

[0033] C) Using polycarbosilane as a silicon source to prepare an impregnating solution, place the carbon substrate in the impregnating solution for impregnation, after impregnating for a predetermined time, pass through a protective gas for pyrolysis, and repeat the impregnation-pyrolysis operation until the obtained Intermediates of predetermined density;

[0034] D) Place silicon particles in a graphite crucible, place the intermediate in the graphite crucible with a graphite rod, and separate the intermediate from the silicon particles, heat the silicon particles ...

Embodiment 2

[0040] Embodiment 2 of the present invention provides a method for preparing a carbon-ceramic friction material, comprising the following steps:

[0041] A) Obtain a prefabricated part made of carbon fiber;

[0042]B) using propylene as the carbon source gas and argon as the carrier gas, depositing and densifying the preform by using a chemical vapor deposition infiltration process to prepare a carbon matrix;

[0043] C) Using polycarbosilane as a silicon source to prepare an impregnating solution, place the carbon substrate in the impregnating solution for impregnation, after impregnating for a predetermined time, pass through a protective gas for pyrolysis, and repeat the impregnation-pyrolysis operation until the obtained Intermediates of predetermined density;

[0044] D) Place silicon particles in a graphite crucible, place the intermediate in the graphite crucible with a graphite rod, and separate the intermediate from the silicon particles, heat the silicon particles t...

Embodiment 3

[0050] Embodiment 3 of the present invention provides a method for preparing a carbon-ceramic friction material, comprising the following steps:

[0051] A) Obtain a prefabricated part made of carbon fiber;

[0052] B) using propylene as the carbon source gas and argon as the carrier gas, depositing and densifying the preform by using a chemical vapor deposition infiltration process to prepare a carbon matrix;

[0053] C) Using polycarbosilane as a silicon source to prepare an impregnating solution, place the carbon substrate in the impregnating solution for impregnation, after impregnating for a predetermined time, pass through a protective gas for pyrolysis, and repeat the impregnation-pyrolysis operation until the obtained Intermediates of predetermined density;

[0054] D) Place silicon particles in a graphite crucible, place the intermediate in the graphite crucible with a graphite rod, and separate the intermediate from the silicon particles, heat the silicon particles ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com